Sleeve phase change heat storage heat exchanger

A phase change heat storage and heat exchanger technology, applied in the field of heat exchange, can solve the problems of small heat exchange area, low heat release and heat storage efficiency, low thermal conductivity, etc., and achieve the effect of increasing heat dissipation area and strengthening natural convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

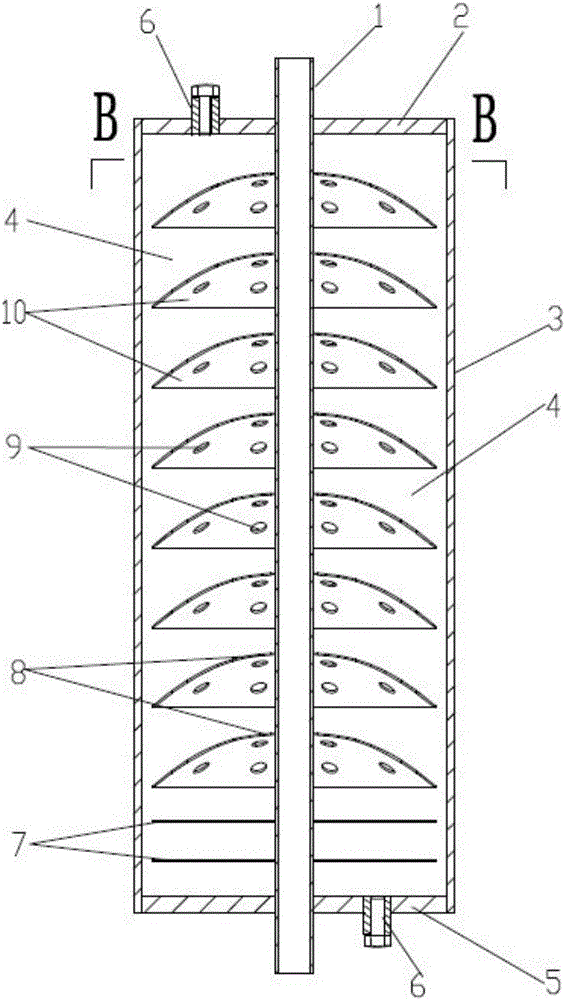

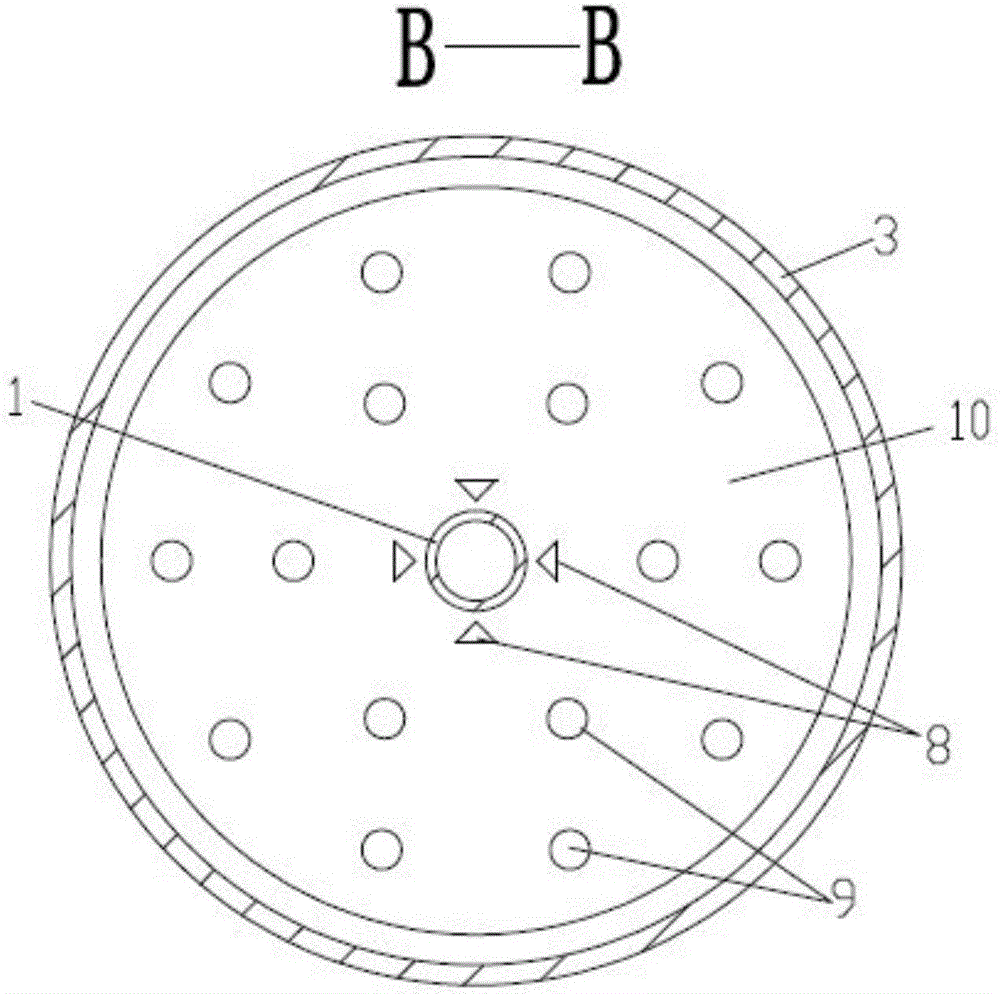

[0015] See figure 1 , 2 . The high-temperature heat exchange fluid can be hot water from a solar water heater, and the heat storage phase change material can be paraffin, fatty acid or molten salt. The preferred heat storage phase change material is paraffin, and the paraffin is stored in the inner sleeve cavity 4 . The solar hot water enters from the upper port of the standpipe 1 and flows out from the lower port of the standpipe 1. At the beginning, the paraffin in the inner cavity 4 of the outer casing is solid. Transferred to paraffin, the paraffin gradually melts after absorbing the heat. When the paraffin is completely melted, the heat storage process of the phase change heat storage heat exchanger is completed, and the heat is stored in the paraffin in the form of latent heat. The reason for adopting the rotating parabolic heat dissipation fins 10 is that, firstly, from the optimization analysis of the heat dissipation per unit weight, it can be known that under a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com