Flexible multi-junction solar cell and fabrication method thereof

A technology of multi-junction solar cells and flexible solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficulty in meeting heat dissipation requirements and low thermal conductivity, and reduce chip application difficulties, reduce weight, and quality Light and flexible cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

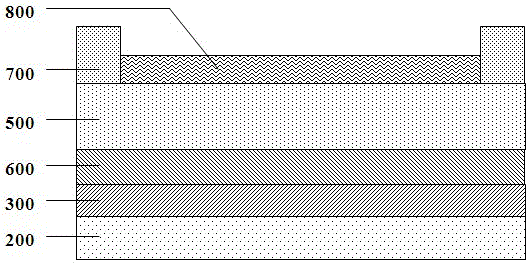

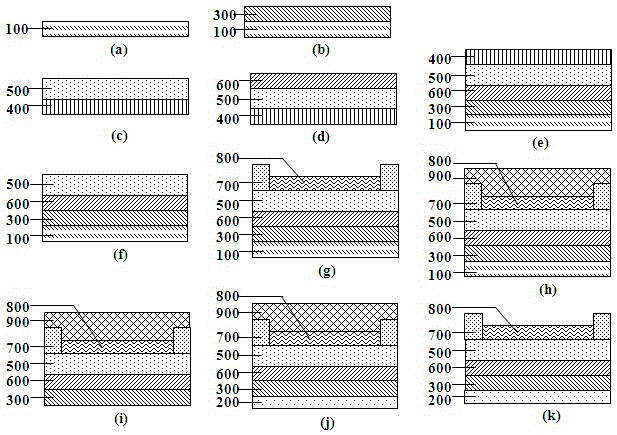

[0033] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention should not be limited thereby. Please see figure 1 , according to a flexible multi-junction solar cell implemented in the present invention, its structure is a flexible metal thin film substrate 200, bonding metals 300 and 600, a multi-junction cell epitaxial structure 500, an upper electrode 700 and an anti-reflection film from bottom to top 800. Combine below figure 2 The multi-junction solar cell is described in detail with the specific fabrication method.

[0034] see figure 2 (a) to (d), provide the first substrate 100 and the flip-chip grown multi-junction cell epitaxial structure, and form a bonding metal layer on the surface of the first substrate 100 and the epitaxial layer 500 of the multi-junction cell epitaxial structure respectively . Specifically, the first substrate 100 is made of a rigid material that can be rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com