Snow and ice removal system for high-voltage line

A high-voltage line, ice and snow technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of high equipment cost, inconvenient installation, unsafe high-altitude work by operators, etc., to achieve excellent anti-icing, simple structure, The effect of excellent ice and snow removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

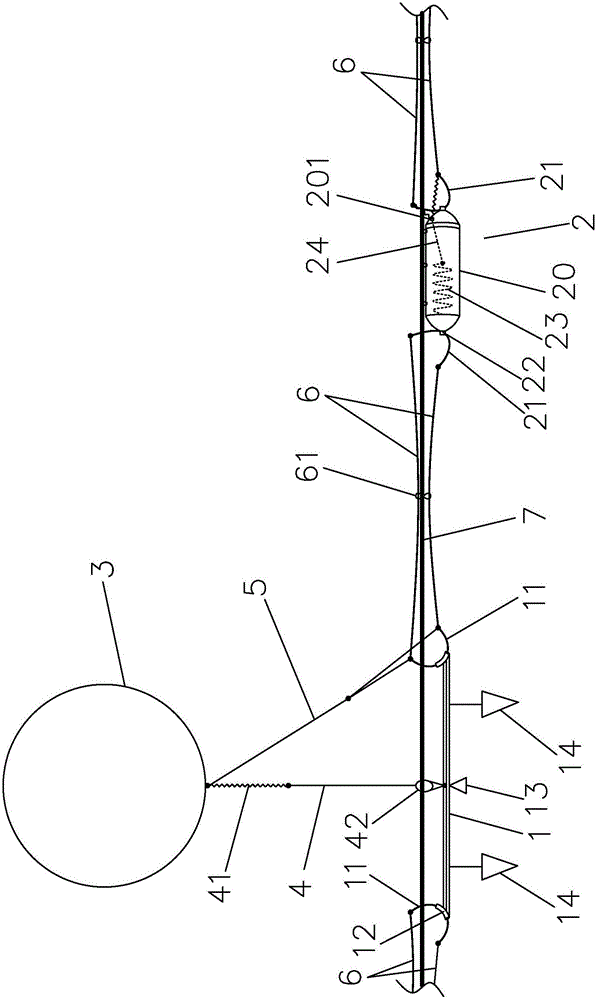

[0027] The present invention relates to a high-voltage line deicing system, which mainly includes balancers 1 and vibrator 2 arranged alternately on the high-voltage line 7, figure 1 Only a small unit consisting of a balancer 1 and a vibrator 2 is given. The snow and ice removal system in this case is composed of a plurality of small units arranged along the high-voltage line 7 . The small units are described in detail below.

[0028] A hydrogen balloon 3 is hung on the balancer 1. Specifically, the center of the balancer 1 is connected to the hydrogen balloon 3 through a connecting line 4. The connecting line 4 has an elastic section 41, and the lower end of the connecting line 4 is set There is a collar 42 that runs through the high voltage line 7 . The balancer 1 mainly relies on the ring to hang below the high-voltage line 7. Of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com