Multistage constant voltage intermittent charge control method

A charging control method and constant voltage charging technology, which is applied in the field of battery management, can solve the problems that the charging intermittent time cannot completely eliminate the battery charging side reaction, increase the initial charging current, prolong the charging time, etc., to weaken the battery polarization reaction , Improve the charging acceptance rate and shorten the charging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

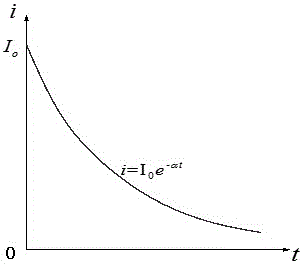

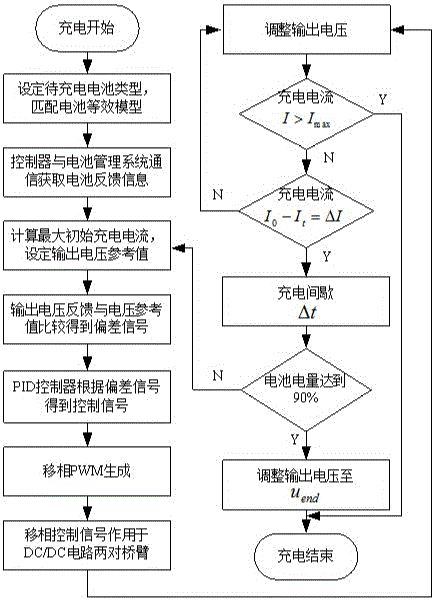

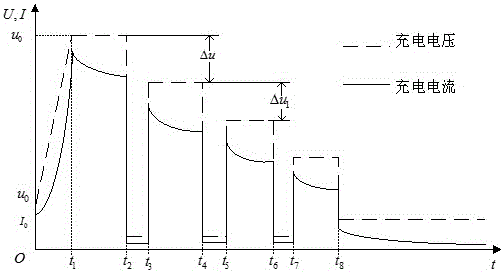

[0032] like Figure 2-4 As shown, this embodiment provides a multi-level constant-voltage intermittent charging control method, which adopts a step-by-step step-down constant-voltage charging method, so that the charging current in the charging sections of each level decreases in the form of an exponential curve, Improve the acceptance rate of charging. During the step-down charging process, a constant small voltage charging interval is used to eliminate the battery polarization reaction. This method can shorten the charging time and ensure that the charging process will not affect the battery performance.

[0033] In this embodiment, the multi-level constant voltage intermittent charging control method divides the charging process of the battery into three stages, namely: charging start, charging adjustment and charging completion, and the respective charging voltages are determined according to the characteristics of each stage, so that the charging The current infinitely ap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap