Motor direct-connected reduction mechanism

A deceleration mechanism and direct-connection technology, applied in the field of motor direct-connection deceleration mechanism, can solve the problems of inconvenient installation and use, complex overall structure, large space occupation, etc., and achieve convenient installation, simple overall structure, and space occupation. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

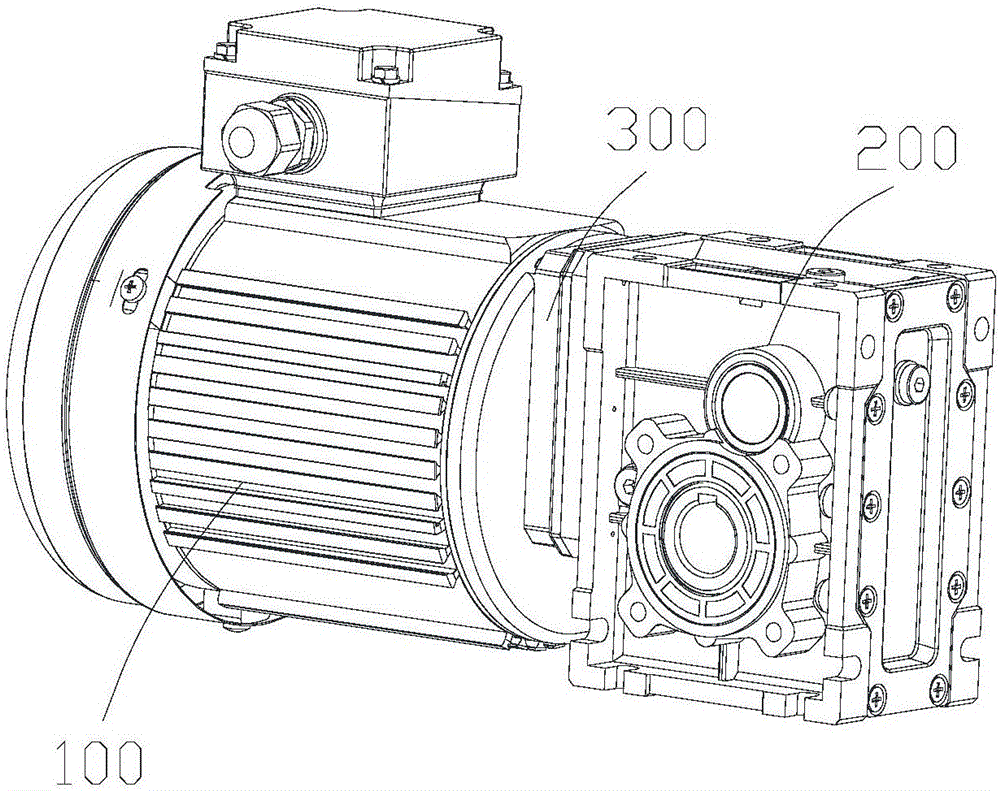

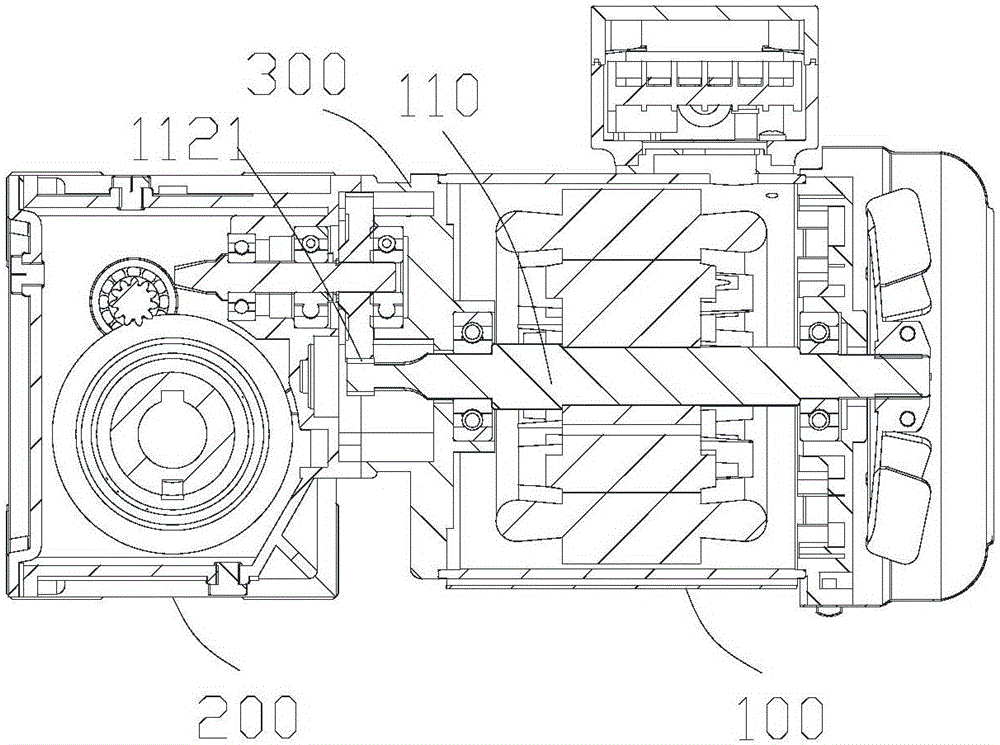

[0041] see figure 1 with figure 2 , this embodiment provides a motor direct connection deceleration mechanism, that is, the motor and the reducer are connected in a direct connection manner, the motor direct connection deceleration mechanism includes a motor main body 100, a reducer main body 200 and a gearbox 300, and the motor main body 100 passes through The gear box 300 is connected to the reducer, and the speed of the motor body 100 is changed to output through the reducer, so as to meet the requirements of different environments.

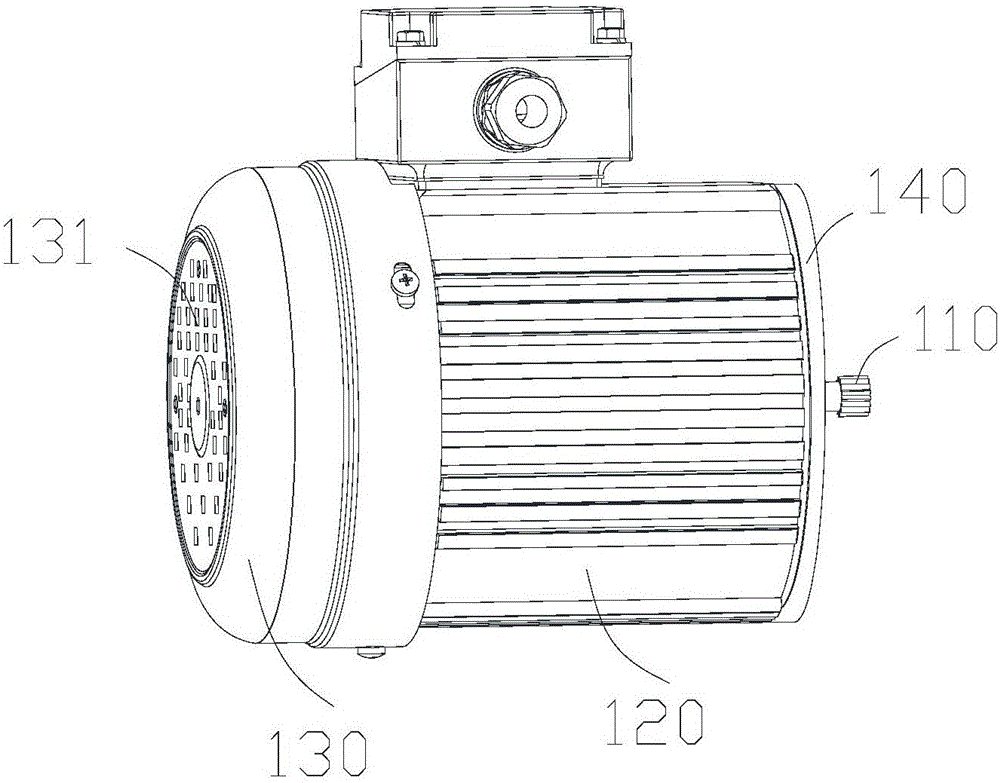

[0042] see image 3, the motor main body 100 is a power output mechanism, and the motor is an electromagnetic device that realizes electric energy conversion or transmission according to the law of electromagnetic induction. In this embodiment, the working principle and internal structure of the motor are not improved. In order to avoid repetitive and cumbersome descriptions, The working principle and internal structure of the motor will no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com