Roll-dividing brake structure

A brake disc, active technology, applied in the direction of brake actuator, engine, elastic engine, etc., can solve the problems of multi-maintenance cost, parts wear, increase the heat generation of the body, etc., so as to reduce the start-up time and reduce the energy loss. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

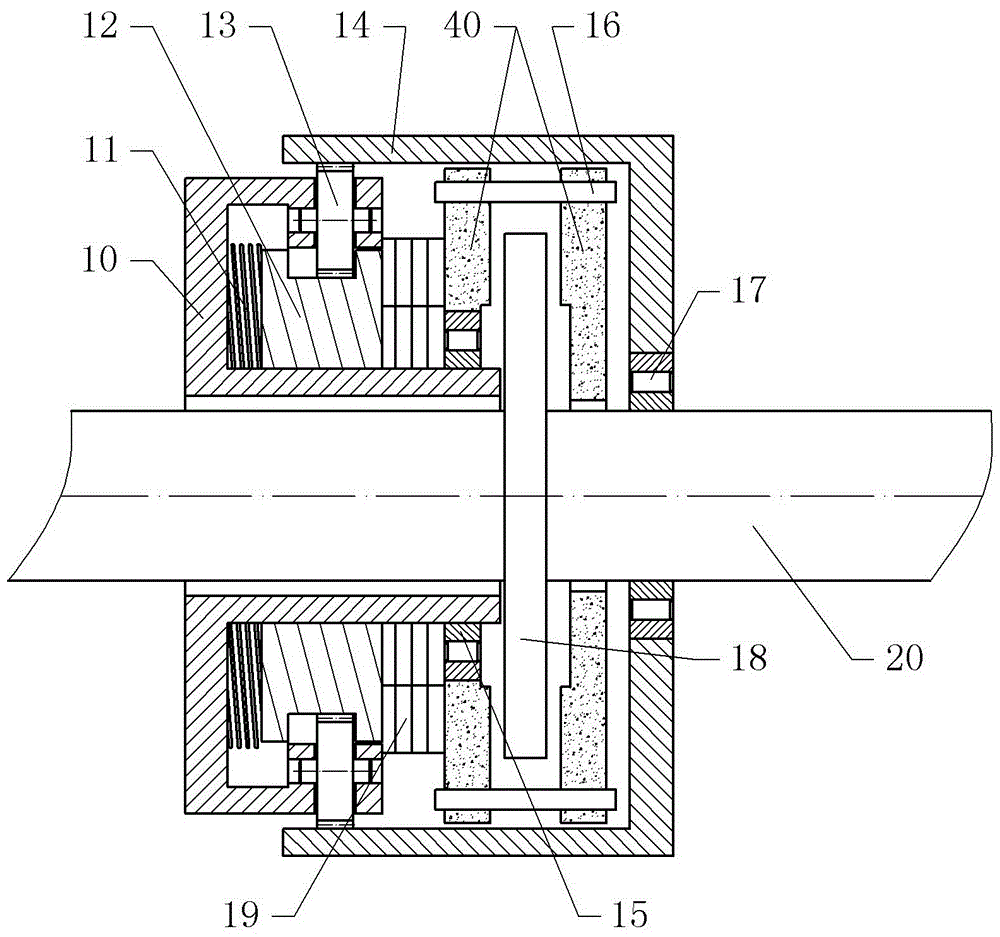

[0018] The reference signs in the accompanying drawings of the description include: housing 10, torsion spring 11, driving turntable 12, planetary wheel 13, passive turntable 14, one-way device 15, connecting shaft 16, one-way device two 17, brake disc 18 , clutch 19, output shaft 20, friction disc 40.

[0019] The embodiment is basically as figure 1 Shown:

[0020] The sub-volume brake structure of the present embodiment includes a housing 10, a hydraulic cylinder and a brake disc 18, the brake disc 18 is fixed on the output shaft 20, the sides of the brake disc 18 are provided with friction discs 40, and the hydraulic cylinder is installed on the on the housing 10, and the hydraulic cylinder can press the friction disc 40 on the brake disc 18; the friction disc 40 is rotationally connected with the housing 10, and a one-way device 15 is provided between the friction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com