Automatic thermoregulator device of grain drier

A grain dryer and automatic adjustment technology, applied in the direction of drying gas arrangement, dryer, heating device, etc., can solve the problems of slow temperature adjustment response speed and low temperature control accuracy, and achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

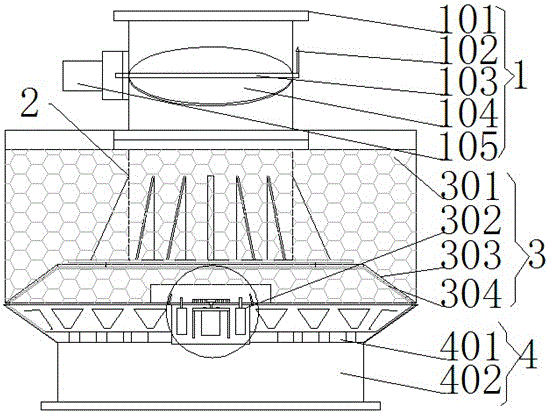

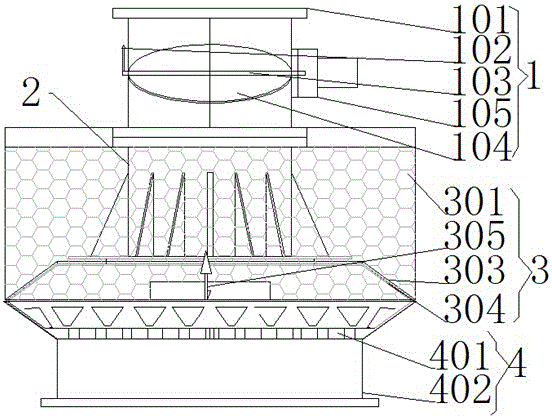

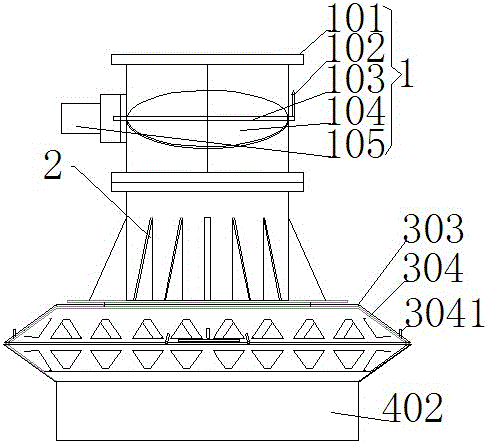

[0023] An automatic thermostat device for a grain dryer, comprising a hot air locker 1, a hot air pipe 2, a cold air intake volume control mechanism 3, and a diversion mechanism 4, the hot air locker 1 is connected to the hot air pipe 2, and the hot air The pipe 2 is connected to the cold air intake volume control mechanism 3, the air guide mechanism 4 is connected to the cold air intake volume control mechanism 3, and the hot air shutoff device 1 is composed of a hot air cylinder shell 101, an indicator arrow 102, a circular shaft 103, a damper plate 104, and a stroke Composed of motor 105, the hot air tube shell 101 is provided with a stroke motor base, and the stroke motor base is provided with a shaft hole, and the shaft hole runs through the hot air tube shell 101 symmetrically, and the shaft hole on the hot air tube shell 101 is flexibly connected to the circle Shaft 103, one end of the round shaft 103 protrudes out of the stroke motor base and is connected to the stroke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com