A device for testing electronic peeling film and its application

A peeling film and electronic technology, which is applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., to achieve the effect of reducing radiation dose, improving development efficiency, and reducing device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

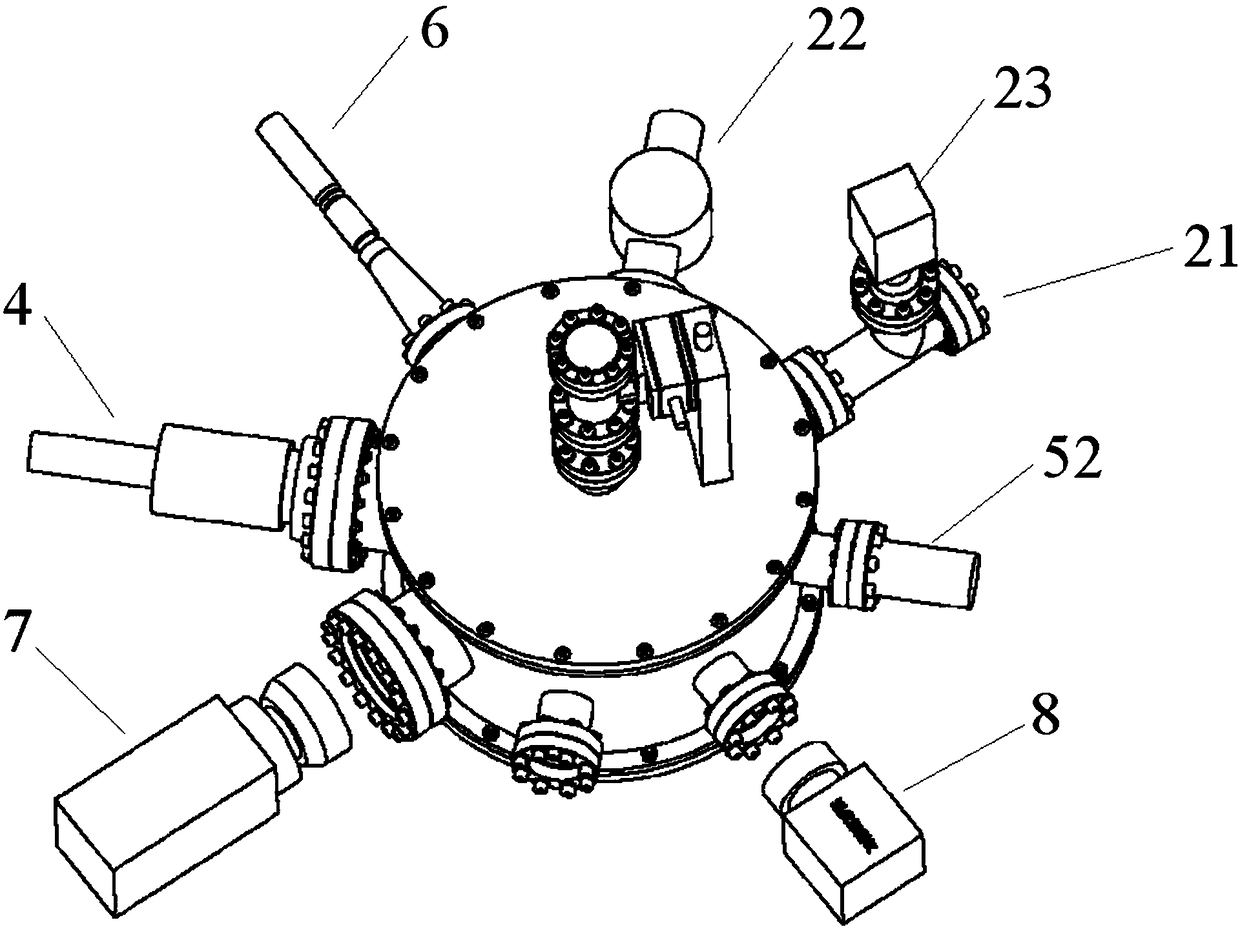

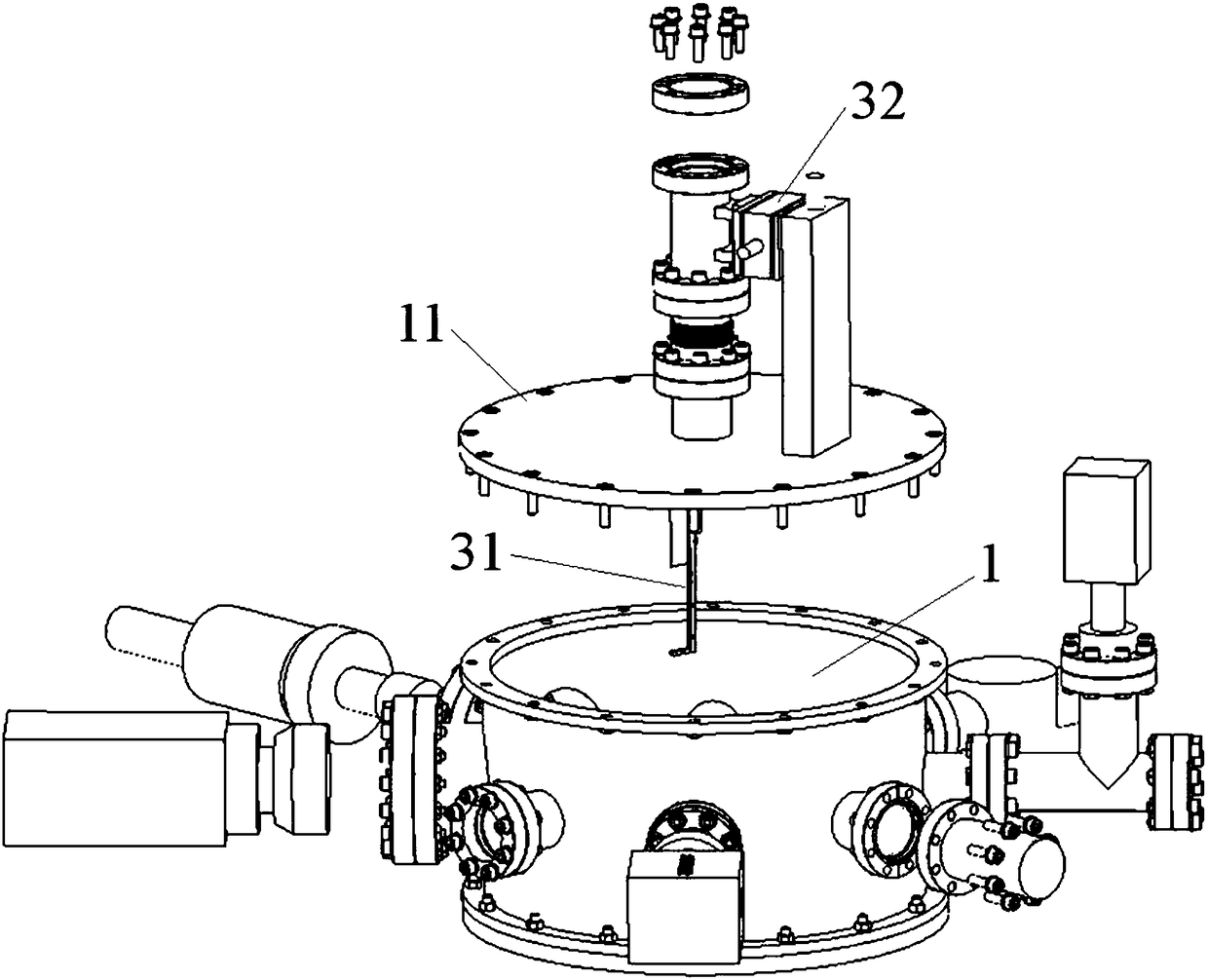

[0033] The electronic peeling film test device in this example, such as figure 1As shown, it includes a cavity 1, a vacuuming device, an electronic peeling film clamping assembly, an electron gun 4, a first Faraday cup, a second Faraday cup 52, an illumination device 6, an imaging device 7, a temperature detection device 8, and an electronic shielding block. The cavity 1 has an openable top cover 11, which forms a closed sealed cavity after the top cover 11 is closed; in this example, the side wall of the cavity 1 is provided with eight external interfaces for connecting vacuum equipment, Electron gun 4, first Faraday cup, second Faraday cup 52, lighting equipment 6, camera equipment 7, temperature detection equipment 8, electronic shielding block, etc. Wherein, the vacuuming equipment is made up of molecular pump 21 and ion pump 22, and molecular pump 21 and ion pump 22 are respectively installed on the two external interfaces on the side wall of chamber body 1, and vacuum is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com