Ultrathin backlight module and touch all-in-one machine based on ultrathin backlight module

A backlight module and all-in-one machine technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of thick products, heavy touch all-in-one machine products, difficulty in designing all-in-one machine solutions, etc., and reduce the number of materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

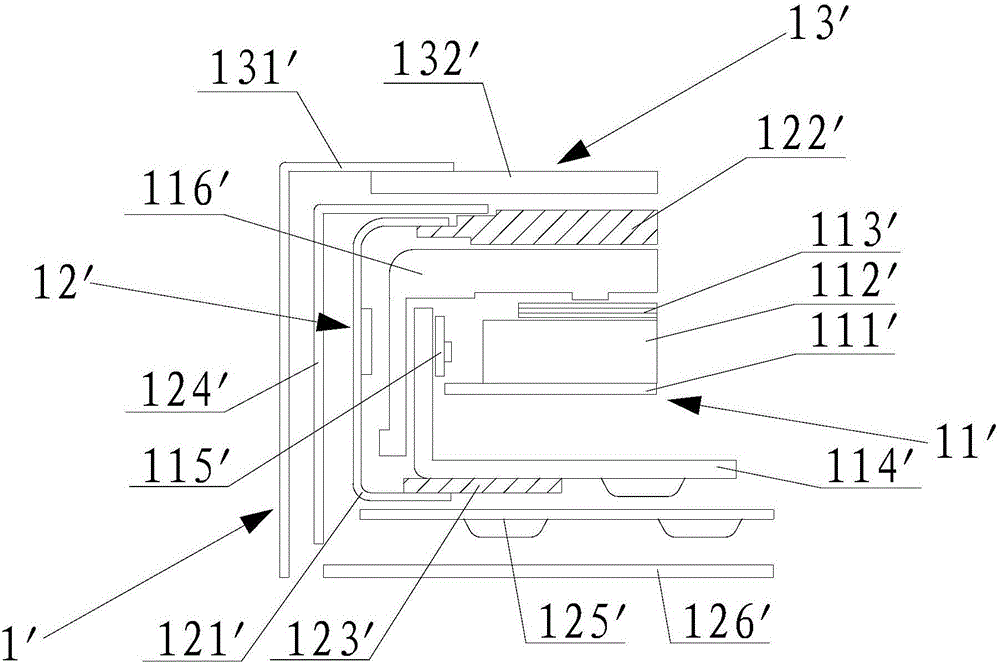

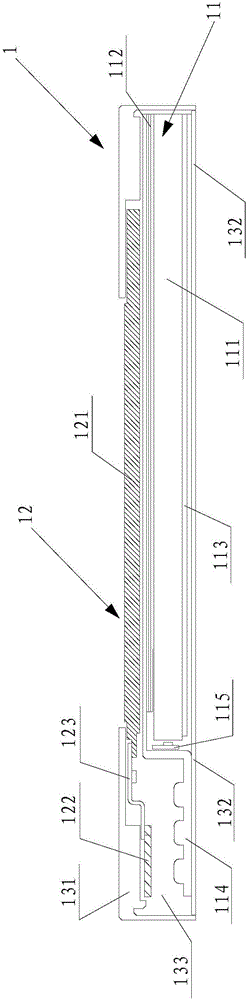

[0021] Such as image 3 The shown ultra-thin backlight module mainly includes a light guide plate assembly 11 , a liquid crystal assembly 12 and a support assembly 13 .

[0022] Wherein, the support assembly 13 includes a frame body 131 and a back plate 132, the back plate 132 is matched with the frame body 131 and the corresponding cover is on the frame body 131, because the frame body 131 has a groove on the side corresponding to the back plate 132 An accommodating space 133 is formed between the frame body 131 and the back plate 132 .

[0023] The light guide plate assembly 11 is installed in the accommodating space 133, and its structure can refer to the structure of the existing light guide plate assembly, which includes a reflective layer 113, a light guide plate 111 and an optical film 112 that are stacked in sequence It can be integrated, such as a filmed glass light guide plate, which is beneficial to reduce the thickness) and the light source 115 corresponding to th...

Embodiment 2

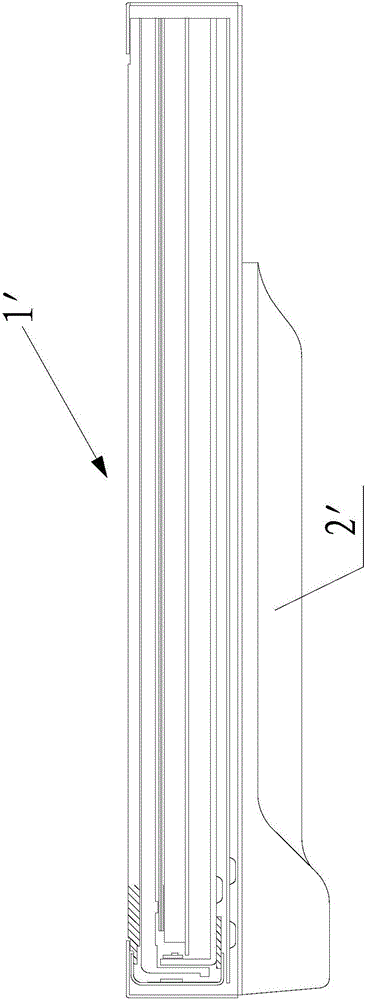

[0026] Such as Figure 4 The touch all-in-one machine shown includes the ultra-thin backlight module 1 and the touch screen 2 in the first embodiment. In order to reduce the thickness of the touch all-in-one machine, the surface of the frame body 131 ( Figure 4 The upper surface of the center) is provided with a first groove portion 134, so that the first groove portion 134 communicates with the accommodating space 133, so that the touch screen 2 is directly fixed in the first groove portion 134 by glue, avoiding the use of additional The aluminum frame can not only reduce the thickness but also reduce the material and cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com