Soy Sauce Raw Precipitation and Self-sinking Technology

A soy sauce and process technology, applied in the field of soy sauce original precipitation and self-sinking process, can solve the problems of low protein utilization, mellow aroma, insufficient sauce aroma, unstable quality, etc., to promote autolysis and protein hydrolysis, reduce the amount of secondary precipitation, Reduces the effect of large particle settling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0018] Experimental example: microscopic examination to confirm the original precipitation test

[0019] Use a microscope to perform microscopic inspection on the original precipitates of unfiltered soy sauce crude oil and filtered soy sauce crude oil:

[0020] ① Take the soy sauce crude oil from the self-sinking tank and self-sink in a 500ml sample bottle. After the original precipitation appears, centrifuge the original precipitation.

[0021] ② Take the soy sauce crude oil filtered by the plate and frame from the self-precipitation tank and self-precipitate in a 500ml retention sample bottle. After the original precipitation appears, centrifuge to collect the original precipitation.

[0022] ③Take a clean glass slide with a concave surface in the middle, dip it in 95% alcohol, and ignite it with an alcohol lamp to sterilize it.

[0023] ④Soak the cover glass in pickling solution for about 10 seconds, rinse with tap water, rinse with distilled water, and wipe clean with lens cleaning ...

experiment example 2

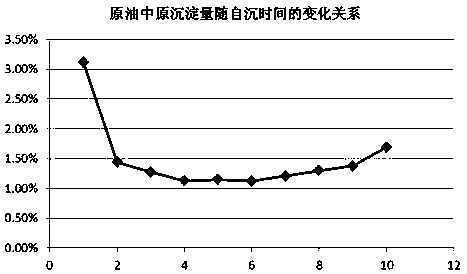

[0028] Experimental example 2: Determining the self-sinking time of the original soy sauce

[0029] Precipitation detection method:

[0030] ① Take a sample of soy sauce crude oil and shake it on a shaker for 10 minutes.

[0031] ②Clean the centrifuge tube, dry it with absorbent paper, weigh the centrifuge tube (capped, the same below), and record it as m 0 .

[0032] ③Pipette 50ml of crude oil after mixing into a centrifuge tube, weigh the total weight, and record it as m 1 .

[0033] ④Put the centrifuge tube containing crude oil in a centrifuge at 4000r / min for 15min.

[0034] ⑤After centrifugation, carefully pour off the supernatant, blot the wall of the centrifuge tube with absorbent paper, and weigh it by m 2 .

[0035] ⑥The amount of precipitation = (m 2- m 0 ) / (m 1- m 0 ).

test approach 1

[0037] ① Take the soy sauce head oil naturally leached from the drying tank as the soy sauce crude oil, take 50T and place it in a 50m³ transfer tank, open and stir for 3 hours.

[0038] ②Pump the oil into 10 50m³ self-sinking tanks while mixing.

[0039] ③The soy sauce head oil in the respective sunken tanks sinks for 0 days, 2 days, 4 days, 6 days, 8 days, 10 days, 15 days, 20 days, 25 days, and 30 days.

[0040] ④After the self-sinking of the soy sauce head oil in the respective sunken tanks is completed, take the oil from the oil outlet 1m from the bottom of the tank for original sedimentation analysis.

[0041] ⑤Microscopic examination of the original sediment samples from 2 days, 6 days, 10 days, and 30 days of sinking to determine the proportion of main sediment types.

[0042]

[0043]

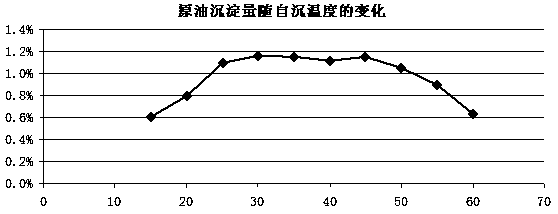

[0044] Analysis: Table 1 and figure 2 It is shown that the relationship between the original sedimentation amount in soy oil crude oil and the self-sedimentation time is firstly decreased and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com