Magnetic separator

A magnetic separator and magnetic system technology, applied in the field of magnetic separators, can solve the problems of short process, high cost, not in line with the concept of energy saving, cost saving, etc. The effect of efficiency and sorting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

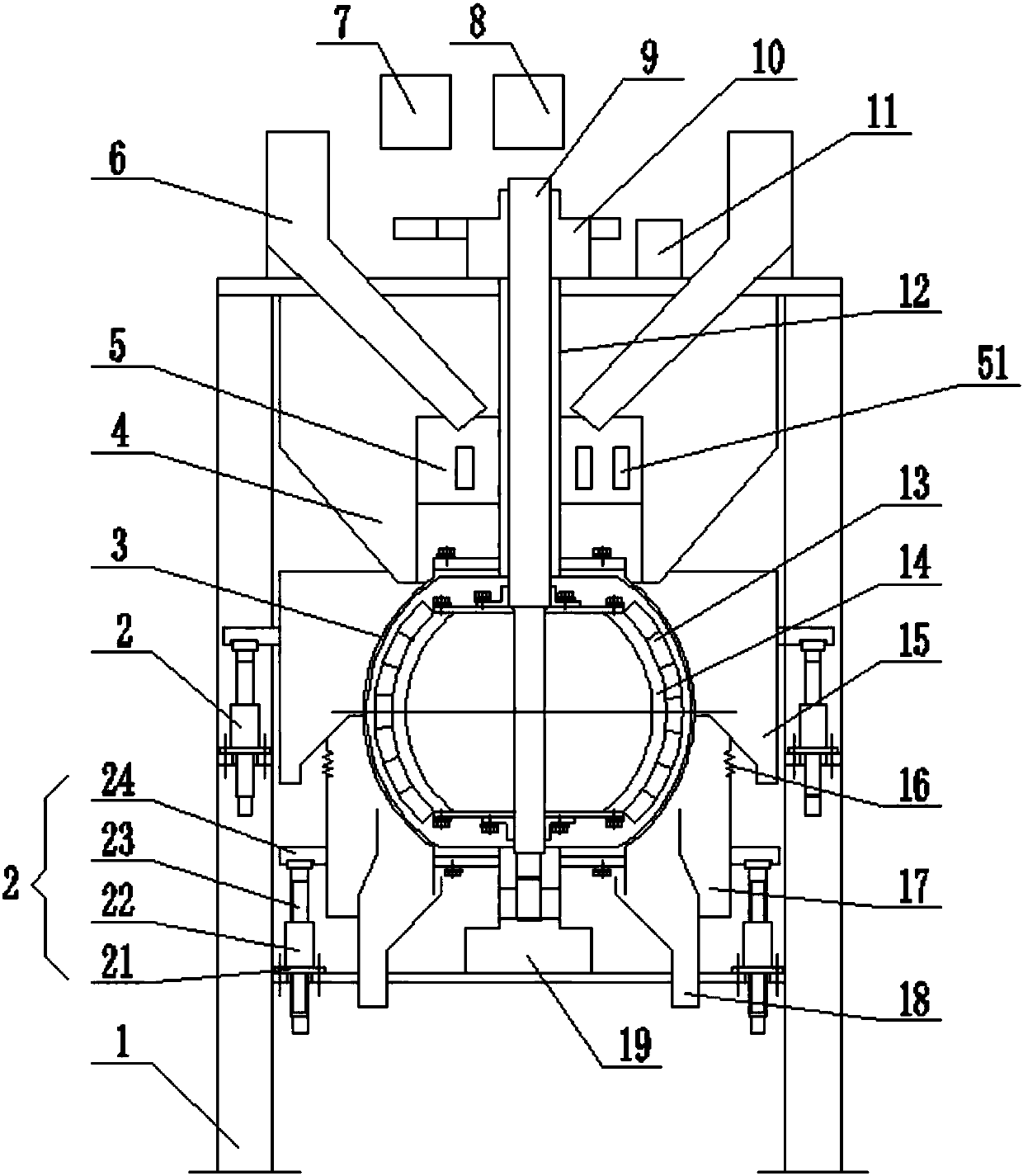

[0030] Such as figure 1 The shown magnetic separator mainly comprises frame 1, sorting body 3 and magnetic system body, and the upper and lower relative ends of frame 1 are respectively fixedly connected with upper support 10 and lower support 19. The body 3 is a spherical body with a hollow cavity, and its outer surface is a spherical sorting working surface. The sorting body 3 is fixedly connected with the second transmission shaft 12 passing through the hollow chamber of the sorting body 3, and the second transmission shaft 12 is a hollow shaft. The magnetic system body is also a spherical body, including a yoke body 14 and several magnets 13. The yoke body 14 is made of a magnetically conductive material, and a threaded hole is processed on it by tapping. The magnet 13 can be made of iron. Oxygen material or NdFeB material, and can be fixedly connected to the outer surface of the yoke body 14 by stainless steel bolts; in addition, the magnet 13 can also be fixed on the ou...

Embodiment approach 2

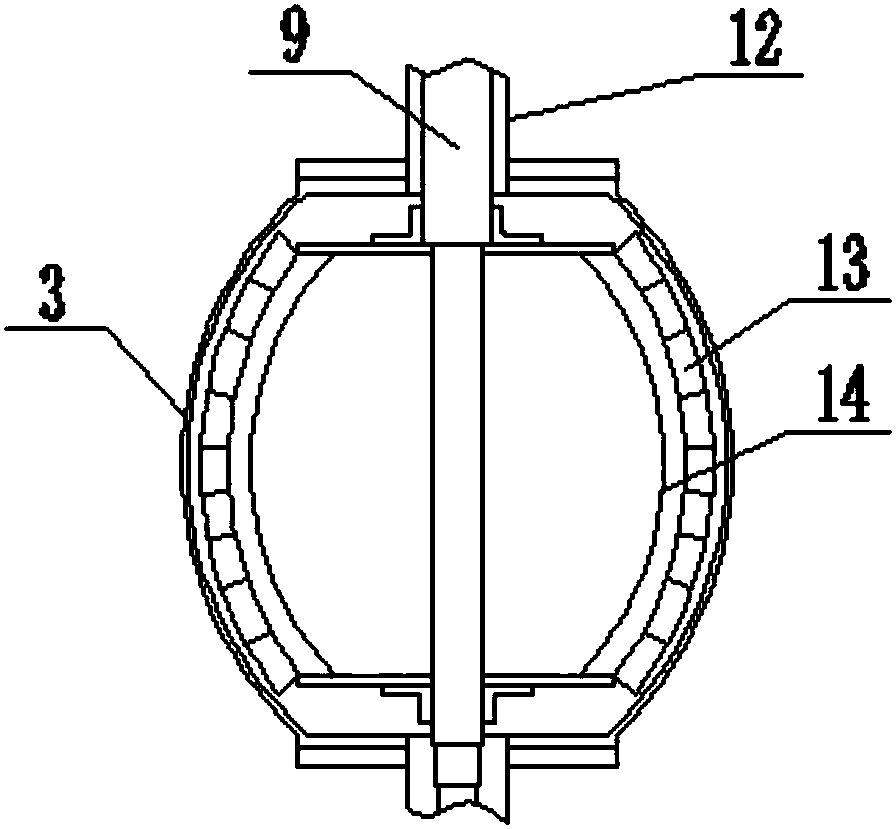

[0038] Such as figure 2 In the magnetic separator shown, the sorting body 3 and the magnetic system body are both of ellipsoidal structure, and the outer surface of the sorting body 3 is the ellipsoidal sorting working surface, and the others are the same as those of Embodiment 1.

Embodiment approach 3

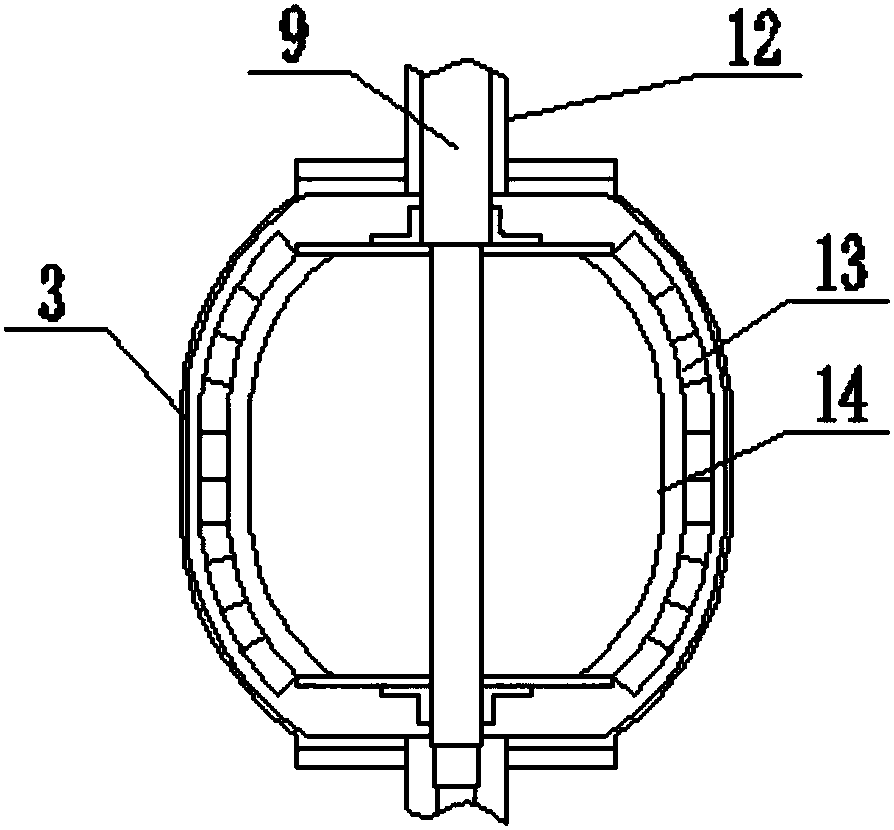

[0040] Such as image 3 In the magnetic separator shown, the sorting body 3 and the magnetic system body are both spherical and cylindrical structures, the two ends of which are spherical structures, and the middle part is a cylindrical structure. Therefore, the outer surface of the sorting body 3 is It is a spheroidal sorting face, and the others are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com