Reed type liquid power ultrasonic gas-liquid-solid multiphase mixer

A liquid dynamic, multi-phase mixing technology, applied in liquid spray devices, spray devices, spray devices, etc., can solve the problems of ignoring solid-phase interaction, large gas volume required, low energy conversion rate, etc., to achieve enhanced atomization fineness. The effect of increasing the sound intensity of ultrasonic waves and improving the fineness of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0038] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

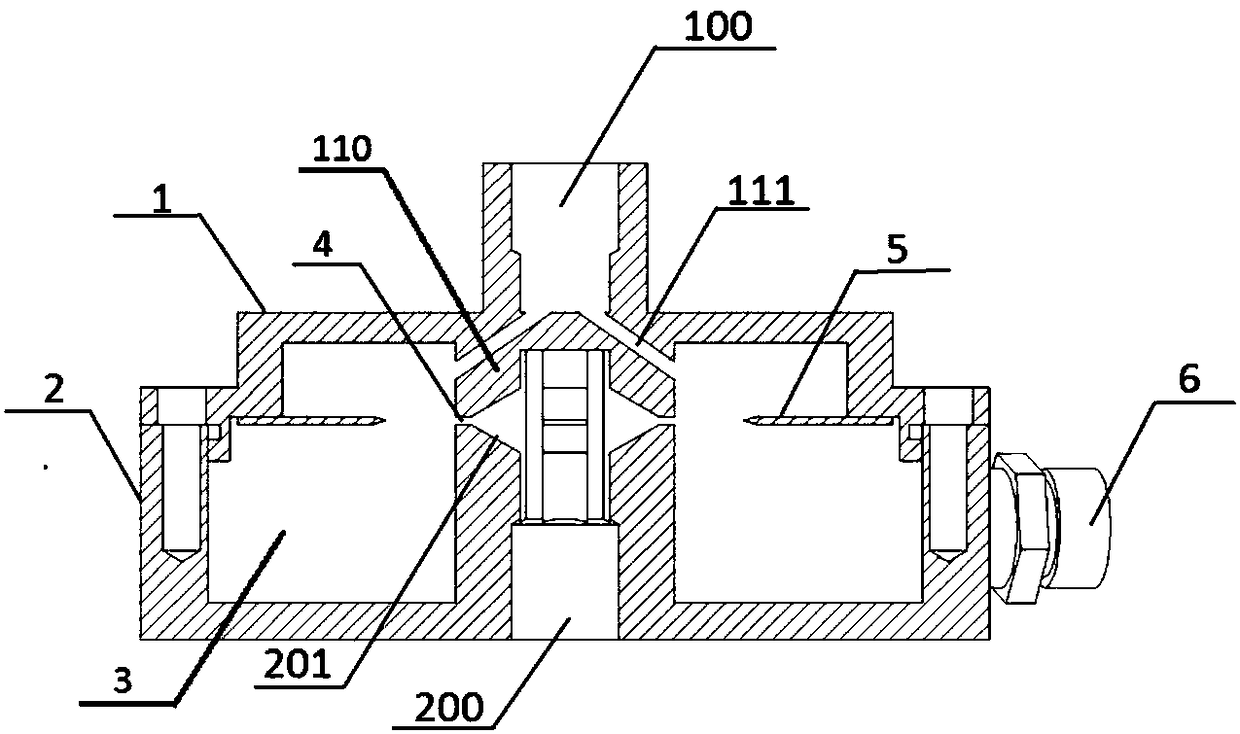

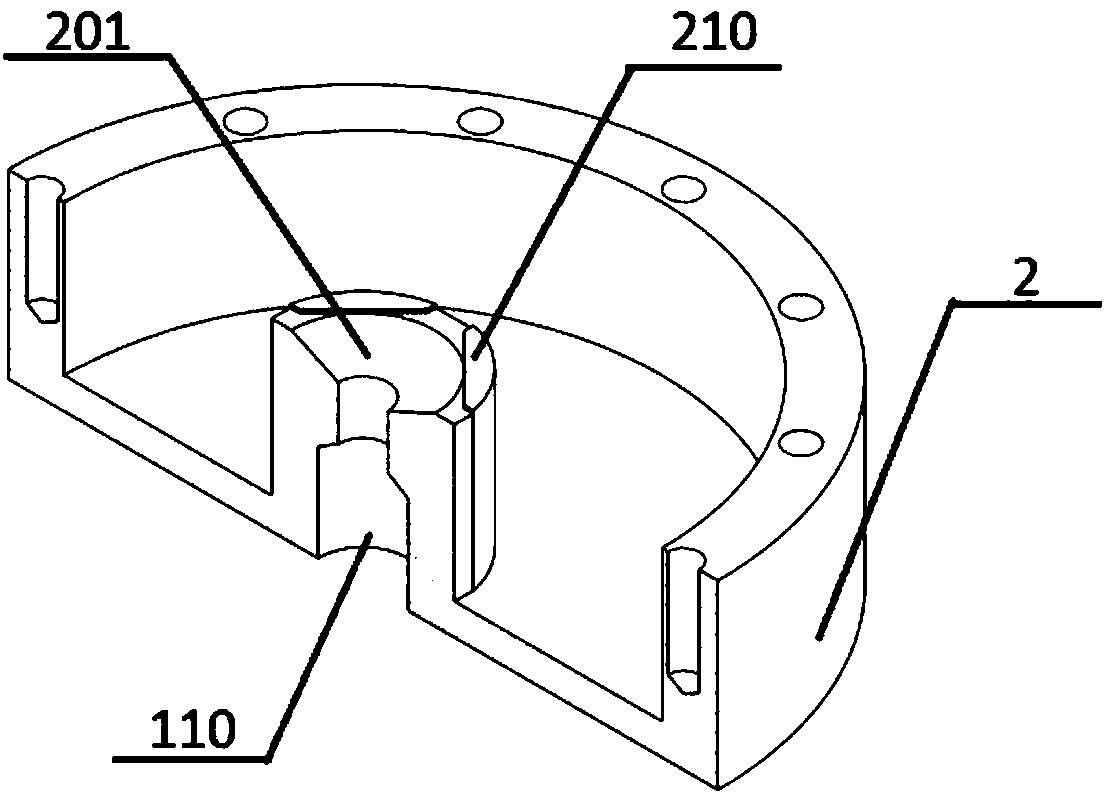

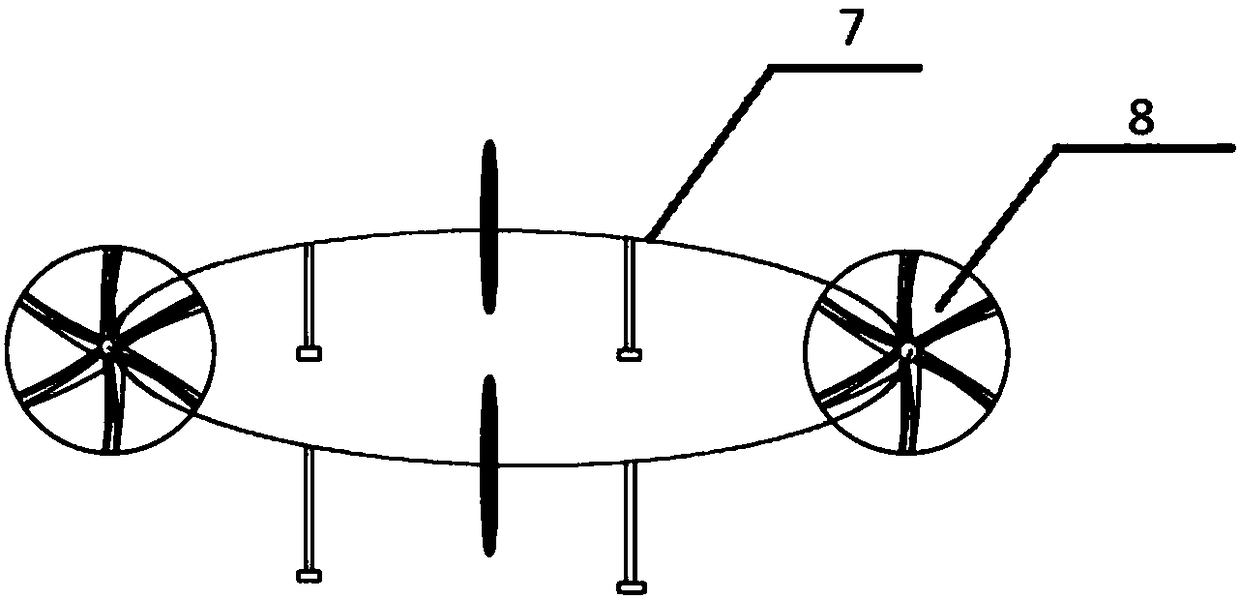

[0039] Such as Figure 1-6 It shows an implementation form according to the present invention, which includes: an upper cover 1 and a lower bottom 2, the upper cover and the lower bottom are detachably sealed and buckled to form a cavity 3, the upper cover 1 A gas introduction pipe 100 is formed on the top surface, and a solid support 110 is arranged on the bottom surface of the upper cover 1 opposite to the gas introduction pipe 100, and a plurality of first nozzle passages 111 are obliquely penetrated on the solid support 110. A nozzle channel 111 communicates with the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com