Multi-point injection evaporation tube of combustion chamber of micro engine

An evaporating tube and engine technology, which is applied in the combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of small contact area, short residence time, poor atomization and evaporation effect, etc., and achieves enhanced heat exchange and atomization fineness. Improve the effect of evenly mixing oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing:

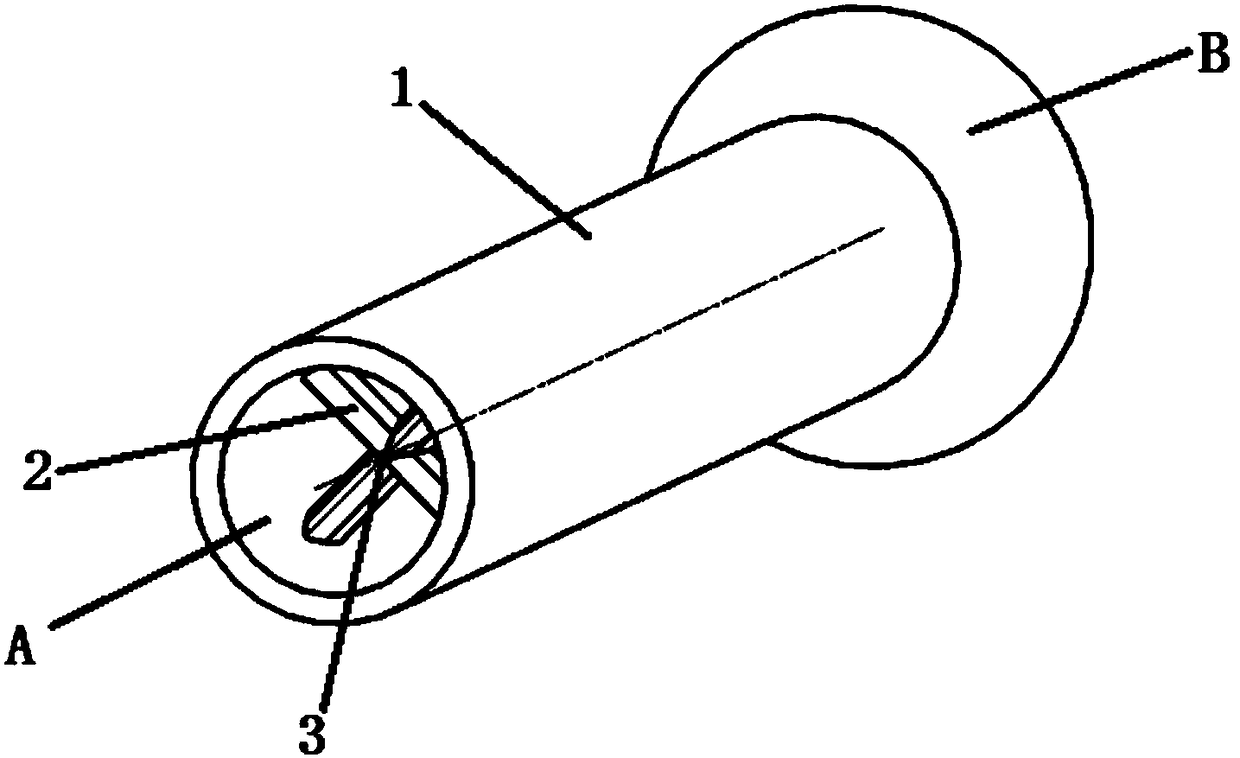

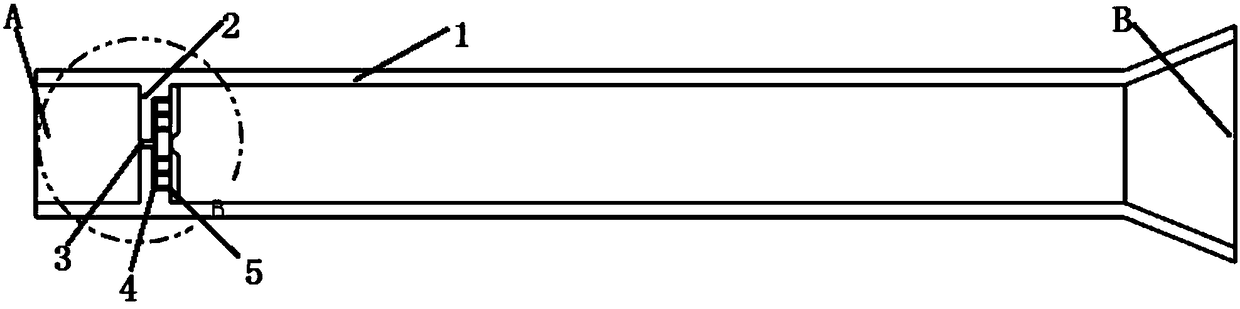

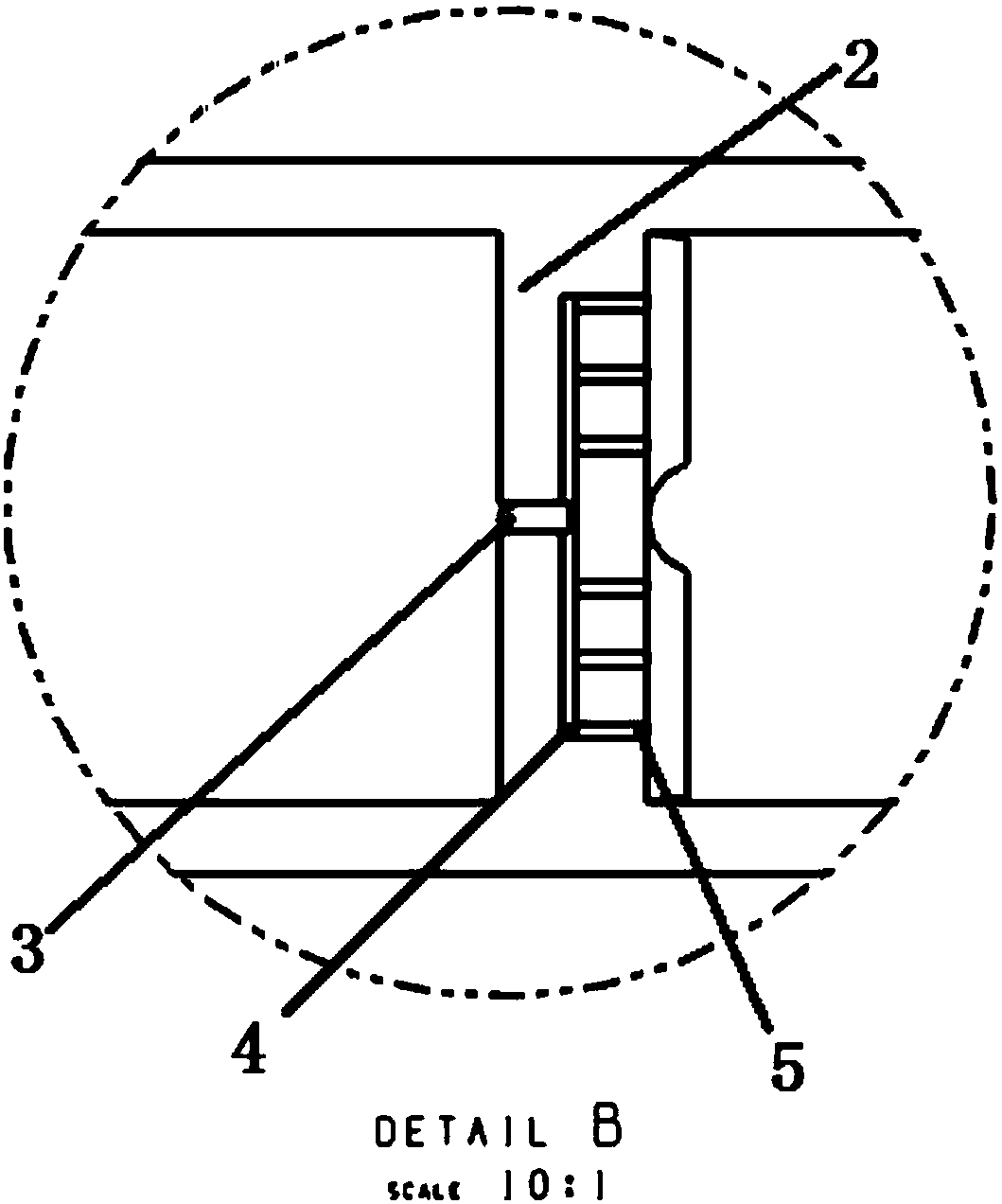

[0019] combine Figure 1 to Figure 3 , the present invention provides a new micro-combustion chamber evaporation tube structure and oil supply mode design that can effectively enhance heat exchange and improve fuel evaporation and atomization. figure 1 It is a three-dimensional diagram of the overall structure of the multi-point jet evaporation tube, which is mainly used to determine the structural shape and geometric distribution of the V-shaped blunt body. figure 2 is a schematic diagram of the central section of the multi-point jet evaporation tube, image 3 It is a partial enlarged view of the layout of the built-in oil circuit of the blunt body of the multi-point jet evaporation tube, which is mainly used to determine the layout of the built-in oil circuit of the blunt body and the position of the oil inlet and outlet holes.

[0020] according to figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com