Swing driving structure of roll plastic molding machine

A driving structure, rotomolding machine technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of viscosity drop, high manufacturing cost, unstable load, etc., to achieve low cost, convenient manufacturing and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

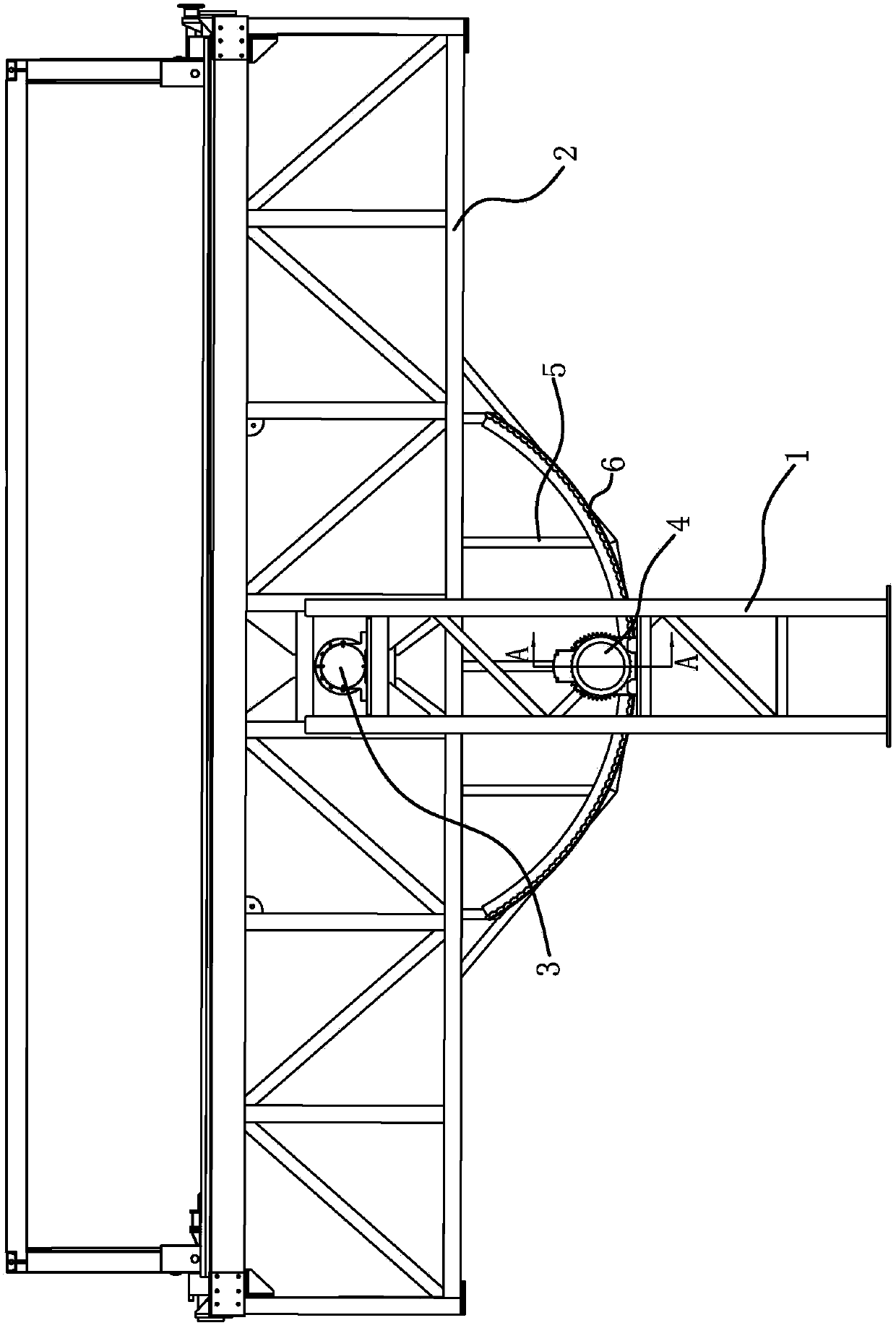

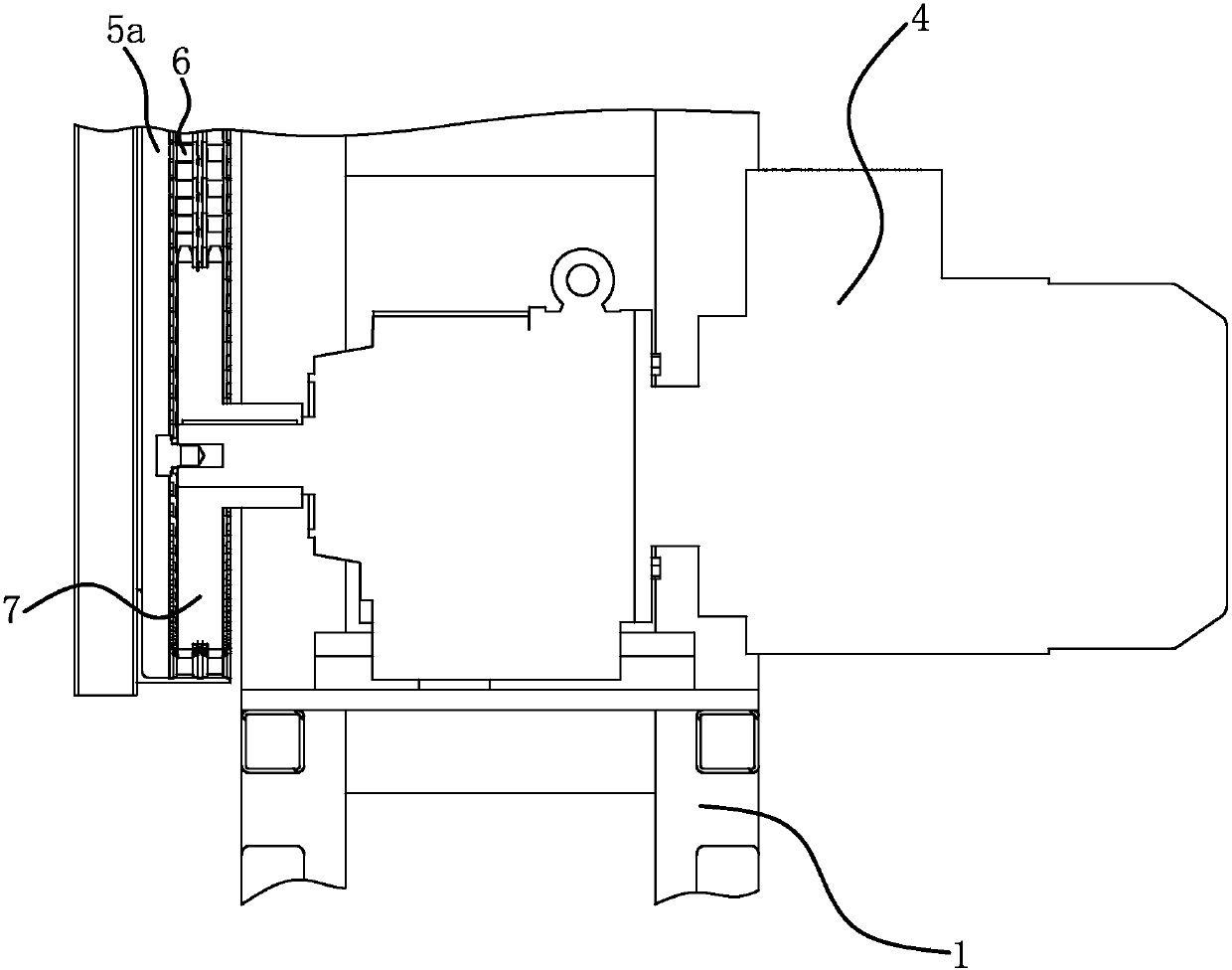

[0017] Such as figure 1 and figure 2 As shown, the rotomolding machine includes a support base 1 and a swing box 2, and the swing box 2 is swingably connected to the support base 1 through a horizontal shaft 3.

[0018] The swing driving structure of the rotomolding machine includes a motor 4, a chain mounting frame 5, a section of chain 6 and a driving sprocket 7.

[0019] The chain mounting frame 5 can adopt a frame structure, and the chain mounting frame 5 has a curved mounting plate 5a in an arc shape. The chain mounting bracket 5 is fixedly connected with the swing box 2; the arc center of the mounting plate 5a coincides with the axis line of the horizontal shaft 3.

[0020] The chain 6 is laid on the inner side of the mounting plate 5a, and the chain 6 is fixedly connected to the mounting plate 5a, so the chain 6 is arranged in an arc shape and the center of the arc shape coincides with the axis line of the horizontal shaft 3. Drive sprocket 7 is positioned at the in...

Embodiment 2

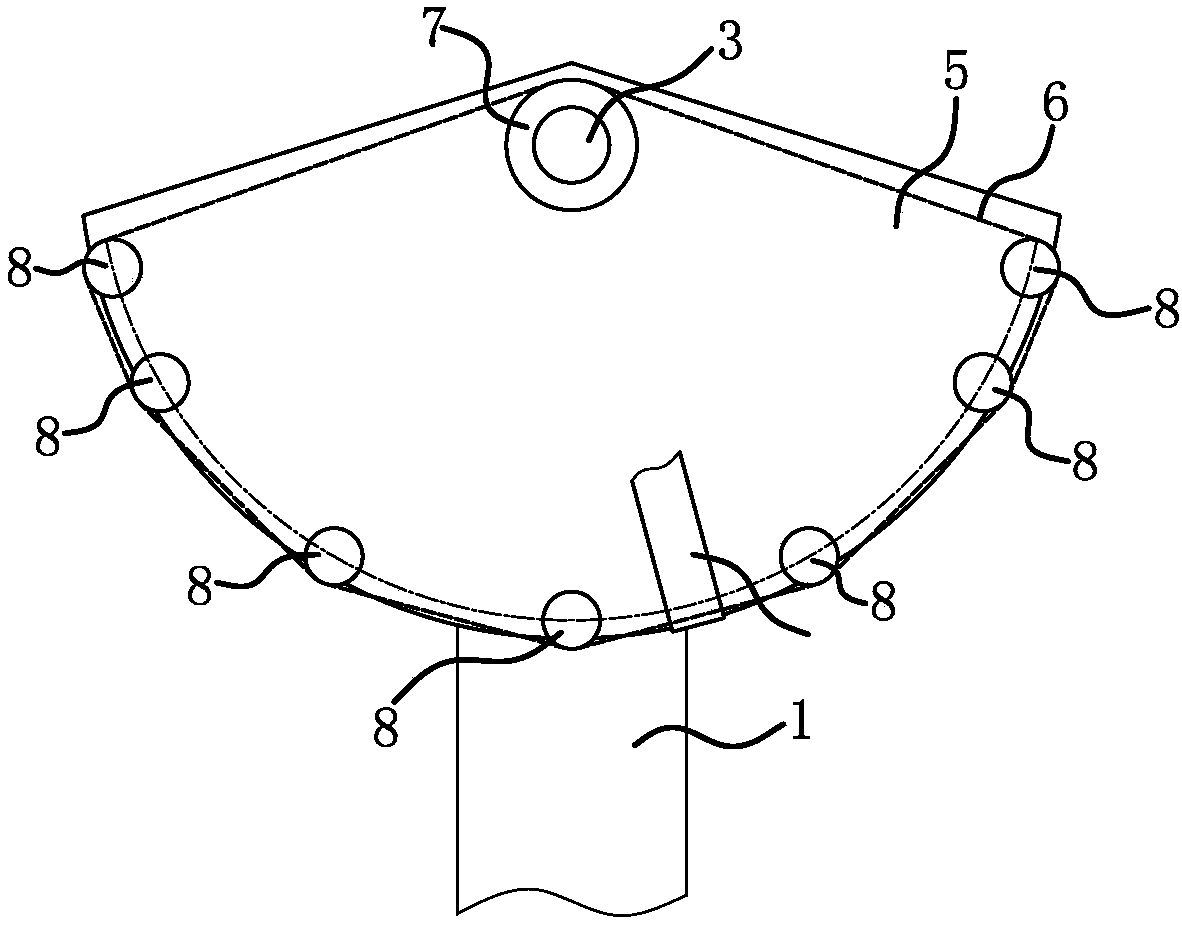

[0023] Such as image 3 As shown, the rotomolding machine includes a support base 1 and a swing box 2, and the swing box 2 is swingably connected to the support base 1 through a horizontal shaft 3.

[0024] The swing driving structure of the rotomolding machine includes a motor 4, a chain mounting frame 5, a section of chain 6 and a driving sprocket 7.

[0025] The chain mounting frame 5 is a plate structure, and the chain mounting frame 5 is vertically arranged with the horizontal axis 3 . The chain mounting frame 5 is fixed on the support base 1 .

[0026] One side of the chain mounting frame 5 is provided with an annular closed chain 6, that is, the chain 6 is located between the chain mounting frame 5 and the swing box 2; image 3 Adopt dotted line to indicate chain 6 in. The inner side of the chain 6 is provided with a plurality of guide sprockets 8 engaged with the chain 6 and a driving sprocket 7 engaged with the chain 6; at least part of the guide sprockets 8 are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com