A method and mold for preparing parts with complex inner cavity

A technology of parts and inner cavity, which is applied in the field of parts with complex inner cavity, can solve the problems that it is difficult to prepare parts with complex inner cavity of pipeline structure, the core material is difficult to be used repeatedly, and the core cannot be demoulded, etc., so as to save The effect of energy consumption, easy core making, and fast core removal speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

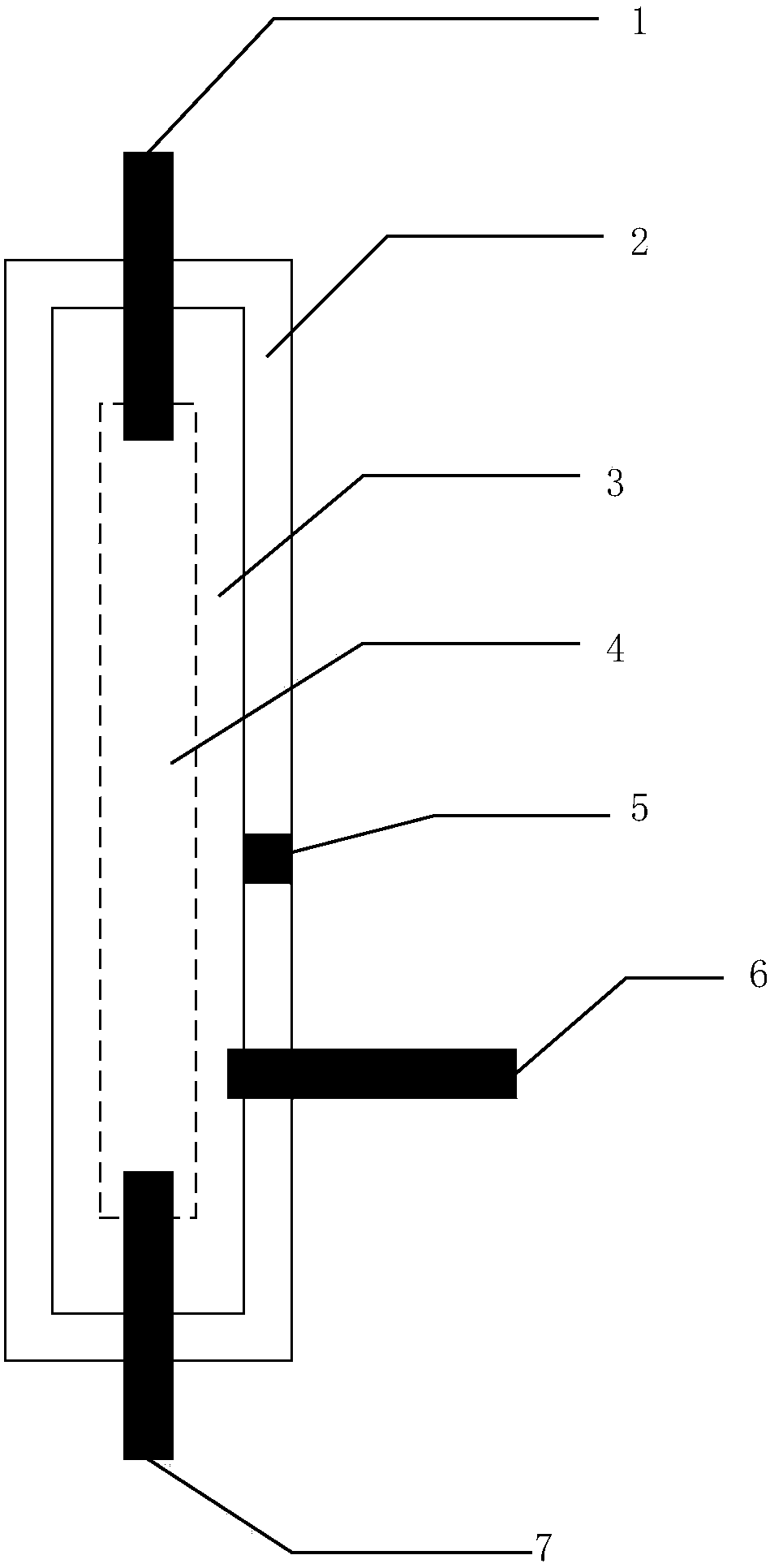

[0038] The implementation process of the technical solution of this embodiment is as follows:

[0039] (1-1) Cast the core constituent material into a block, and then process it into a spiral shape by mechanical processing; or directly inject the core constituent material into a mold with a spiral cavity, and obtain a spiral shape after cooling and demoulding core. Then wrap a layer of polytetrafluoroethylene non-porous film on the outside of the core as an isolation film, and sealant or sealing strip to seal the film interface.

[0040] (1-2) At room temperature, wrap the continuous carbon fiber pre-impregnated with medium-temperature curing epoxy resin on the surface of the polytetrafluoroethylene non-porous film of the above-mentioned core, and then put it into the mold, and wrap the polytetrafluoroethylene non-porous film at both ends of the core. The film is sealed to the mold wall, and the sealant or bead seal ensures that the core and the composite preform are gas-sepa...

Embodiment 2

[0052] The implementation process of the technical solution of this embodiment is as follows:

[0053] (2-1) Raise the temperature of the core constituent material to 130°C, inject it into a zigzag nylon sealed bag with a prefabricated cavity, and obtain a core with a nylon sealed bag on the outside and a fusible core constituent material inside. , and then wrap a layer of polytetrafluoroethylene non-porous film outside the core to seal. The isolation membrane for the above core is composed of a double layer of nylon with high strength and a non-porous polytetrafluoroethylene membrane that is not bonded to the composite material.

[0054] (2-2) At room temperature, unidirectional continuous carbon fiber or glass fiber prepreg pre-impregnated with medium-temperature curing epoxy resin or polyester or benzoxazine is spread on the non-porous film surface of polytetrafluoroethylene of the above-mentioned core , and then put it into the mold, fix and seal the outlets of the nylon ...

Embodiment 3

[0059] The implementation process of the technical solution of this embodiment is as follows:

[0060] (3-1) Prepare a prefabricated cavity shaped as a U-shaped nylon sealed bag, insert one or two strip-shaped heating resistors inside, so that the length of the heating resistor is similar to the length of the U-shaped cavity; The material is heated to 140° C. and injected into the cavity of the nylon sealed bag to obtain a mold core covered with a nylon sealed bag and a fusible core constituent material inside. Then wrap a non-porous film of polytetrafluoroethylene outside the core to seal;

[0061] (3-2) At room temperature, the unidirectional continuous carbon fiber or glass fiber pre-impregnated with high-temperature curing epoxy resin or double horse resin is wound on the non-porous film surface of the polytetrafluoroethylene of the above-mentioned core to obtain a composite material prefabricated body, and then Put it into the mold, fix and seal the outlet of the nylon s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com