Segmental mold with celectromagnetic vulcanization tread

A technology of vulcanized tread and flexible mold, applied in the field of molds for rubber production, can solve the problems of inconsistent actual measurement value and inconsistent measurement performance, and achieve the effect of convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

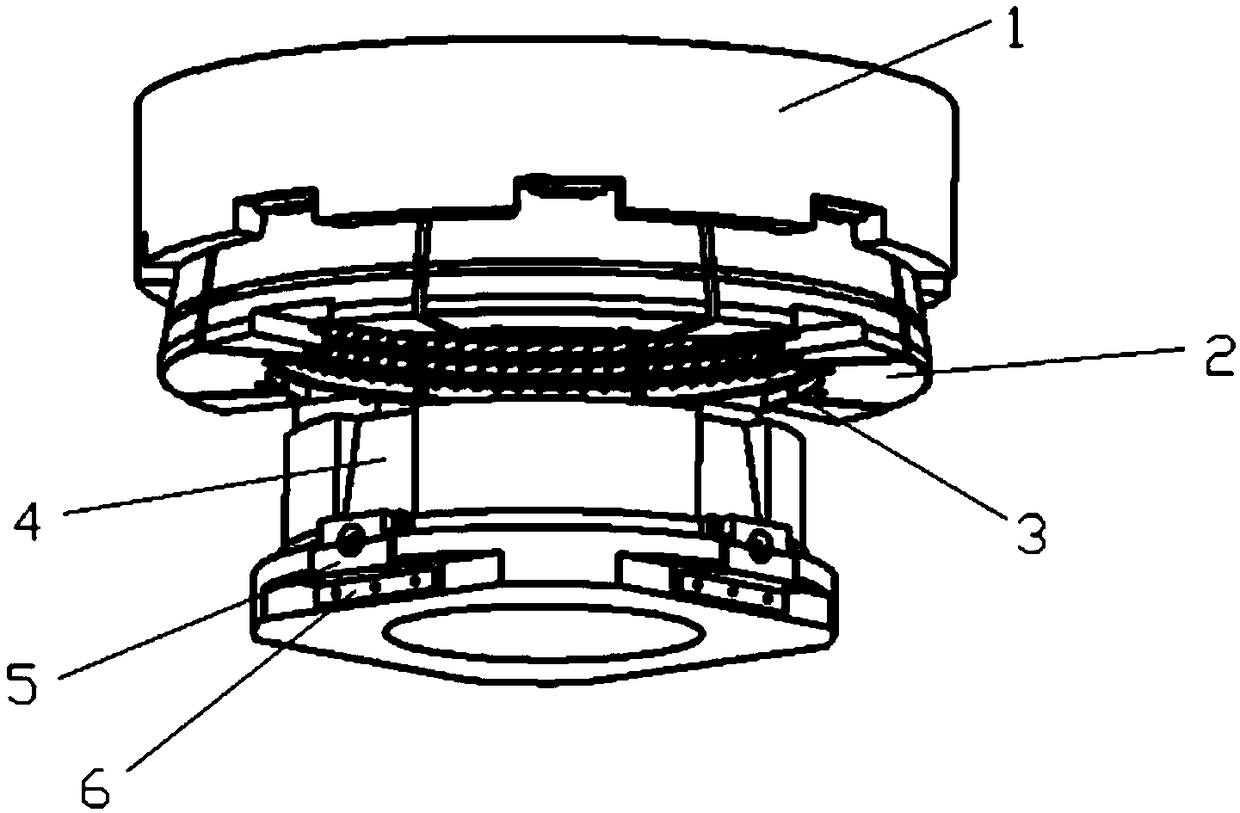

[0027] The main structure of an electromagnetic vulcanized tread active mold mold involved in this embodiment includes an upper cover 1, a bow seat component 2, a pattern block component 3, an inner mold core 4, a runner component 5, a flange component 6 and a sealing ring 7 The inside of the upper cover 1 is nested with a bow-shaped seat composition 2, and the upper cover 1 and the bow-shaped seat composition 2 are snap-connected. connection, the inner mold core 4 and the upper cover 1 are set independently, and the bottom of the inner mold core 4 is evenly spaced with four sets of runners to form 5, the inner mold core 4 and the runners to form 5 are connected by flanges 6, and the inner mold core A sealing ring 7 is arranged between 4 and the flow channel composition 5 .

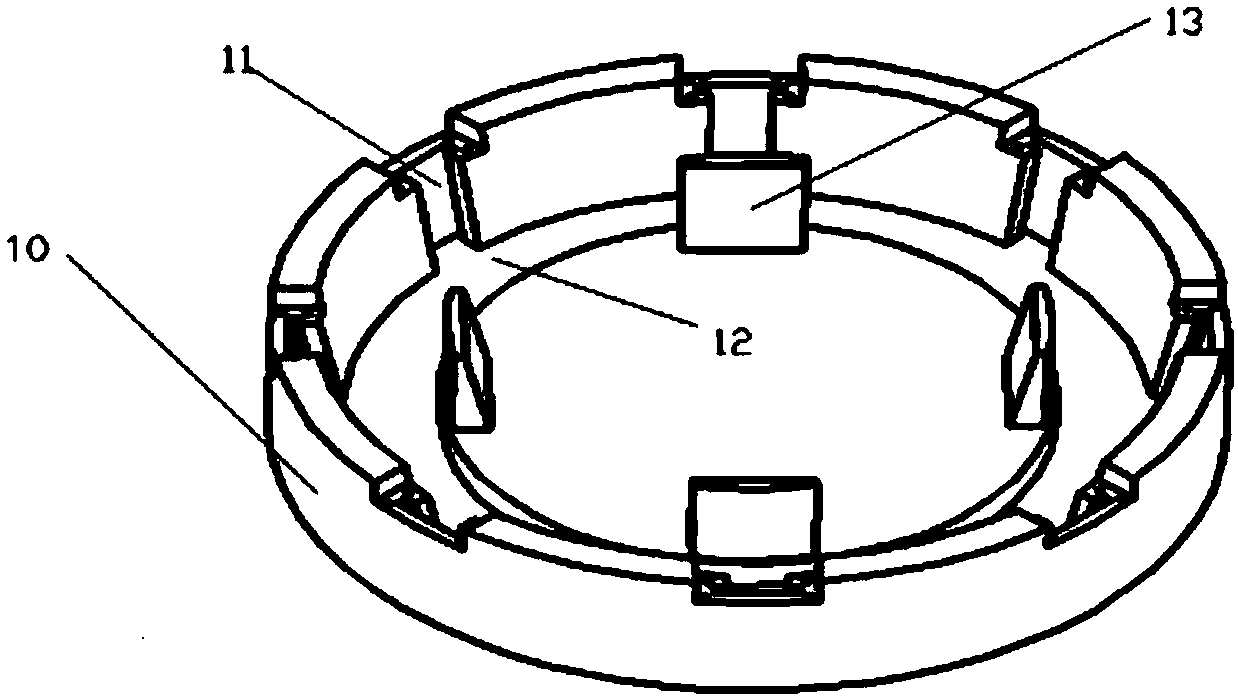

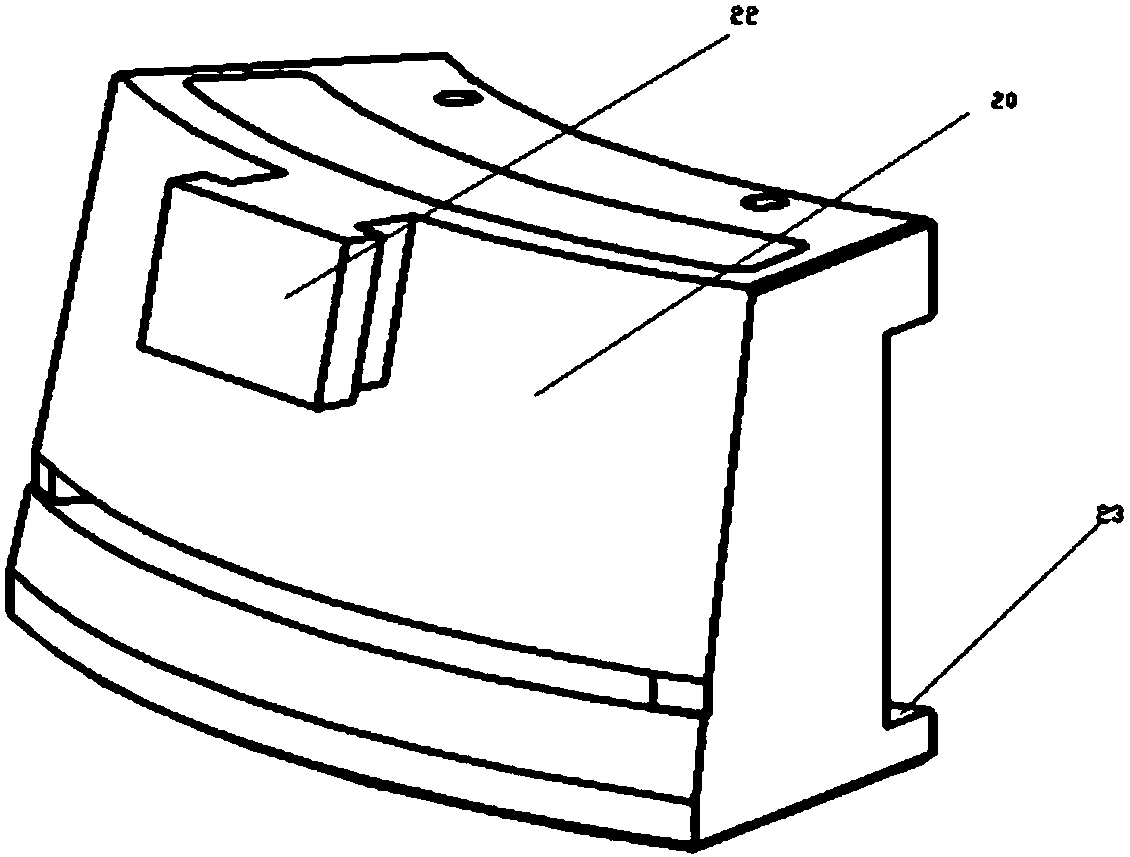

[0028] The main structure of the upper cover 1 involved in this embodiment includes a side ring 10, a T-shaped groove 11, a top plate 12 and a wedge block 13; The top of the top is provided with a top pl...

Embodiment 2

[0036] When the electromagnetic vulcanized tread active mold mold involved in this embodiment is used in conjunction with the gear pump injection machine, the gear pump injection machine selects a single screw with a diameter of 200mm, and the total volume of the tread is 19000cm 3 For example, 4 gear pump injection machines can complete the injection within 20 seconds, and the injection volume of each gear pump injection machine is 4750cm 3 , the injection speed is 1.4525t / h; there are two gate layout schemes, one is to use 8 pairs of point gates for inner wall injection, and the other is to use 4 line gates for side injection; the gear pump can not only increase the head pressure , and can reduce the extrusion temperature of the rubber compound: the operation of the gear pump reduces the screw pressure of the extruder, the heat generation of the rubber compound is reduced when the rubber is transported by the extruder, and the flow path of the rubber compound in the gear pump...

Embodiment 3

[0038] When the electromagnetic vulcanized tread movable mold mold involved in this embodiment cooperates with the gear pump to extrude the short fiber compound rubber, the transmission characteristics of the positive displacement transmission of the gear pump can greatly reduce the pressure fluctuation, ensure the stability of the head pressure, and improve the short-term The appearance quality of fiber compound rubber can improve the stability of rubber extrusion, facilitate the dispersion of short fibers and other fillers, reduce the Payne effect, and ensure that the compound rubber maintains good dispersion at high speeds; Internally pressurized, the pressure is higher when passing through the extruder head, and the degree of adhesion between the layers increases, which ensures the quality of the extruded product; with the increase of the single screw speed, the Mooney viscosity decreases, ensuring that the short fiber The dispersion in the rubber compound makes the quality...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com