In-mold integrated shoe sole and its manufacturing process

An integrated, in-mold technology, applied in shoe soles, footwear, footwear, etc., can solve the problems of inability to complete the setting effect, unvulcanized rubber sheets cannot be vulcanized, and labor intensity is high, so as to avoid glue opening and edge misalignment affecting products Beautiful appearance, avoid environmental pollution and physical injury of workers, and improve the effect of product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

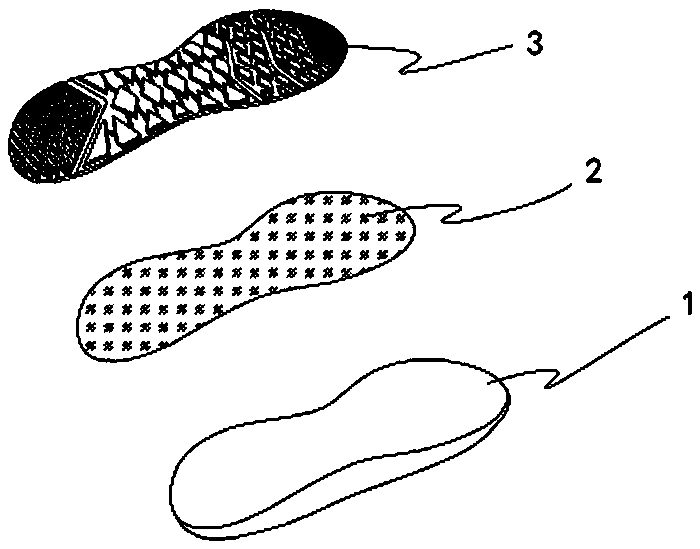

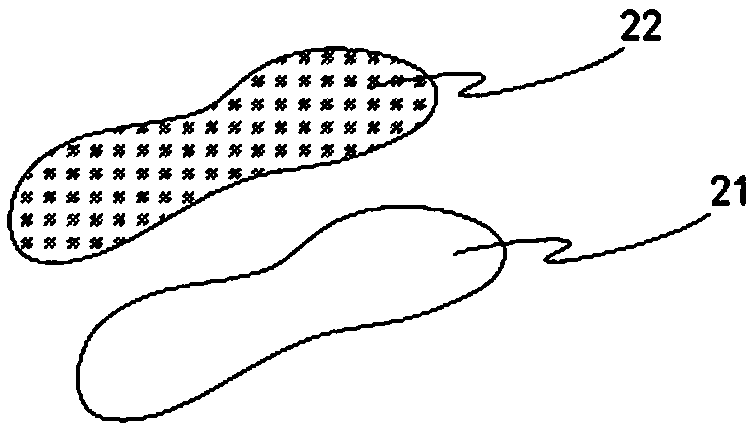

[0021] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that an in-mold integrated shoe sole includes an EVA midsole 1, a hot-melt adhesive film 2, and a vulcanized rubber sheet 3. The hot-melt adhesive film 2 includes a PET outer layer 21 and an attached On the viscose particle layer 22 on the PET outer layer 21, the viscose particle layer 22 comprises EVA97% with a VA content of 28%, zinc stearate 1.5%, stearic acid 1.5%, and the PET outer layer 21 and the The viscose particle layer 22 can be separated from each other, and the shape and size of the hot melt adhesive film 2 are compatible with the shape and size of the bottom surface of the EVA midsole 1; the vulcanized rubber sheet 3 is made of unvulcanized rubber The sheet and the hot melt adhesive film 2 are integrally vulcanized in the rubber mold, and the shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com