Automobile anti-skid system and its control method

An anti-skid, automobile technology, applied in the field of automobile anti-skid system and its control, can solve the problems of increasing the wear and tear of the braking system, increasing the maintenance cost of the whole vehicle, and the vehicle being unable to pass, so as to improve the utilization rate, improve the off-road ability, and continuously work without any problems. effect of interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

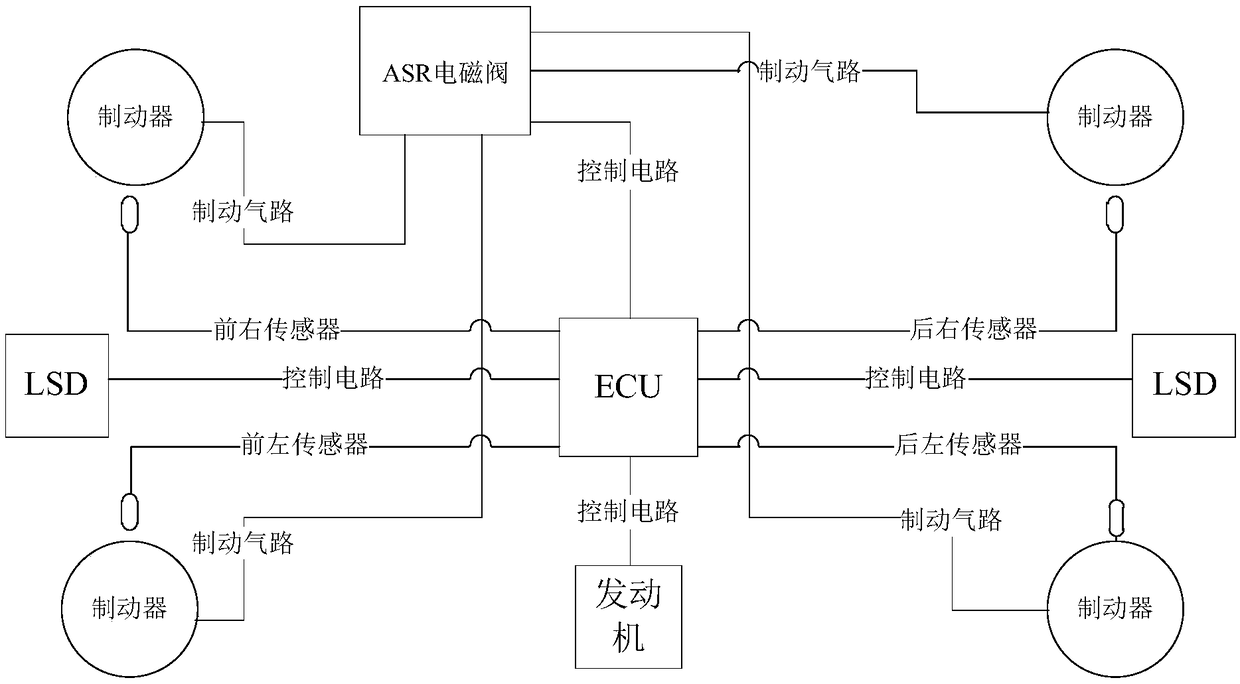

[0019] Such as figure 1 Shown, the present invention all assembles inter-wheel limited-slip differential LSD or inter-axle differential at the front, middle and rear axles of the drive axle of full-drive automobile, and installs ASR driving anti-skid control system at driving wheels additionally.

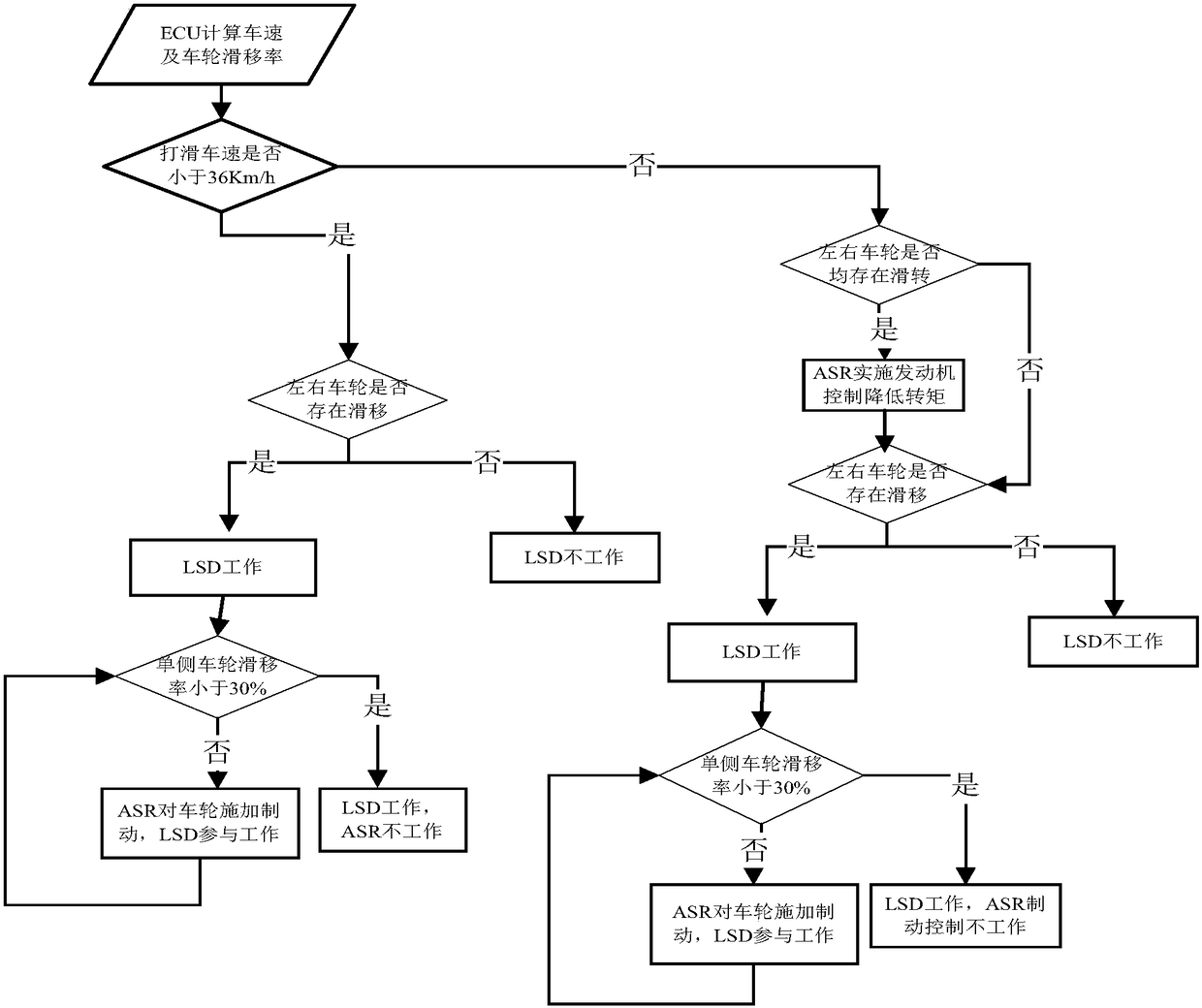

[0020] The electronic control unit ECU of the vehicle obtains the vehicle speed signal and slip ratio signal of the off-road vehicle through the sensors at the four wheels, and the electronic control unit performs cooperative control on the limited slip differential and the driving anti-slip control system according to the vehicle speed signal and the slip ratio signal . The limited-slip differential is connected to the electronic control unit through a control circuit, and after receiving the control signal sent by the electronic control unit, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com