Damping gas cylinder transfer trolley

A technology of transfer vehicles and gas cylinders, which is applied to trolleys, motor vehicles, single-axis trolleys, etc., can solve certain problems such as safety, collision, and inconvenient hand-carrying, and achieve the effect of simple structure and strong safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

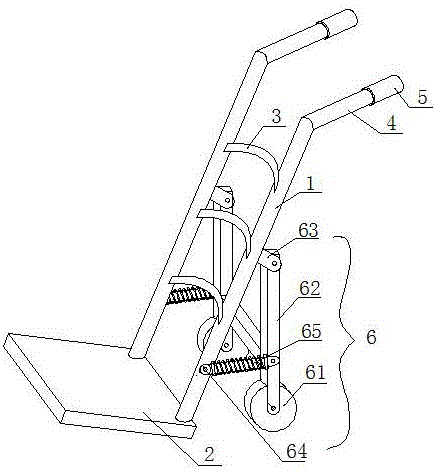

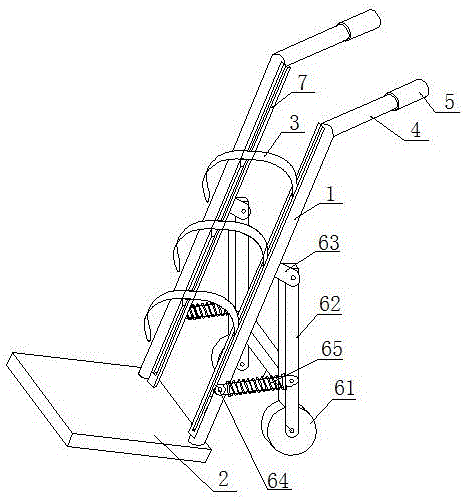

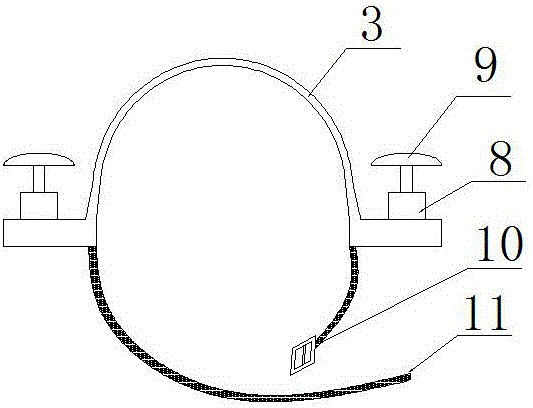

[0017] Reference attached figure 1 : A shock-absorbing gas cylinder transfer vehicle, comprising a vehicle frame 1 fixedly formed by parallel support rods, a gas cylinder supporting plate 2 for conveniently placing gas cylinders is fixedly arranged at the bottom of the vehicle frame 1, and the gas cylinder supporting plate 2 is connected with the vehicle frame 1 vertical arrangement; the middle part of the vehicle frame 1 is provided with an arc-shaped support bar guardrail 3 matching the size of the gas cylinder, preferably two or more in number, and a plurality of support bar guardrails 3 are evenly distributed on the vehicle frame 1. A handle 4 is set on the top of the vehicle frame 1, and the handle 4 is provided with a rubber sheath 5 that is convenient to hold. During use, the friction between the hand and the handle 4 can be increased by the rubber sheath 5 to avoid slipping; A shock absorber 6 is provided, and the shock absorber 6 includes a roller 61, a roller bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com