Trunk lid

A trunk lid and closed-cell foam technology, which is applied in the upper structure sub-assembly, layered products, transportation and packaging, etc., can solve the problems of board-core debonding, weak bonding, poor dipping, etc., to achieve Increase bond strength, improve wettability, good integrity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

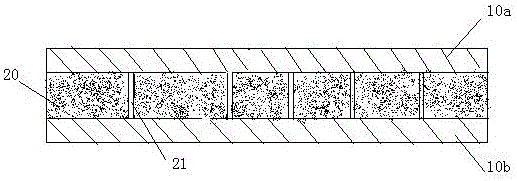

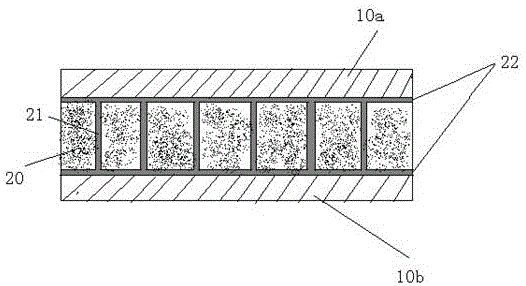

[0015] Such as figure 1 , the trunk lid of the present invention comprises an upper carbon fiber composite material layer 10a and a lower carbon fiber composite material layer 10b, and a closed-cell foam material layer 20 is arranged between the upper carbon fiber composite material layer 10a and the lower carbon fiber composite material layer 10b. The foam material layer 20 is provided with a through hole 21 penetrating through the upper and lower surfaces of the closed-cell foam material layer 20, between the upper carbon fiber composite material layer 10a and the closed-cell foam material layer 20, between the lower carbon fiber composite material layer 10b and the closed-cell foam material layer Resin is filled between the porous foam material layers 20 and in the through-holes 21 of the closed-cell foam material layers 20 . The function of the closed-cell foam material layer 20 is to reduce the amount of carbon fiber in the trunk lid, thereby reducing the raw material cos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com