Process for hoisting whole assembly section of upper-layer building living zone of ship

A technology for superstructures and living areas, applied in ship construction, ship parts, ship design, etc., can solve problems such as rigidity reduction, achieve the effects of small actual deformation, shorten cycle time, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

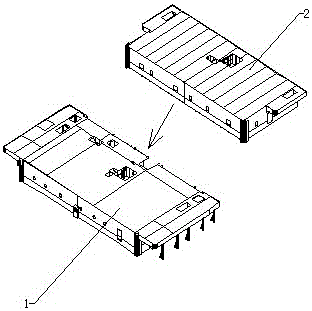

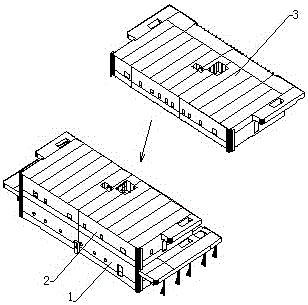

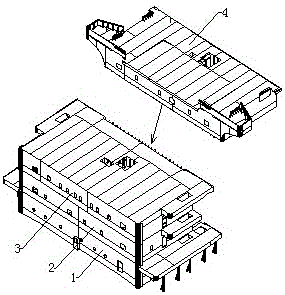

[0015] In this embodiment, the hoisting process of the general section of the ship's superstructure living area, the specific steps of the hoisting process are as follows:

[0016] (1) Use a laser theodolite to draw the center line and square line of the combined section on the ground in the predetermined position area;

[0017] (2) The general section of the living area is arranged on the side of the dock, and its fore and stern direction should be consistent with the fore and stern direction of the main hull; Segment 3, segment 4 of 70.12t and segment 5 of 33.35t, such as figure 1 As shown, hoist segment 2 above segment 1 connected to it, descend slowly, pause at 200mm from the positioning position, adjust the position of the segment, and then continue to descend until it is connected to the lower segment; figure 2 As shown, hoist segment 3 above the connected segment 2, descend slowly, pause at 200mm from the positioning position, adjust the position of the segment, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com