Automatic collection device

A technology of automatic material collection and equipment, applied in the direction of packaging, etc., can solve the problems of poor safety, high cost, and low efficiency, and achieve the effect of low cost, reasonable equipment design, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

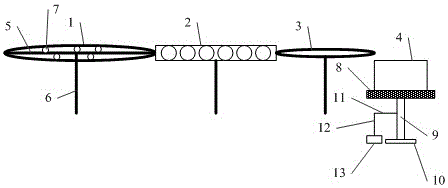

[0031] In Embodiment 1, automatic receiving equipment is provided, please refer to Figure 1-Figure 4 , the equipment includes:

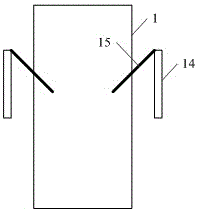

[0032] Arranged from left to right: the first rubber conveyor belt 1, the roller conveyor belt 2, the second rubber conveyor belt 3, and the receiving box 4, wherein the first rubber conveyor belt is installed on the first support plate 5, so The first support plate is fixed above the ground through the first bracket 6, and both the first support plate and the first rubber transmission belt have a mesh structure, and the connection between the first support plate and the first rubber transmission belt There are N cylinders 7 evenly distributed among them, and the N is a positive integer greater than or equal to 10. A spring post 14 is provided on the left and right sides of the first rubber conveyor belt, and the lower end of the spring post is connected to the ground. The upper end of the column is connected to one end of the baffle plate 15, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com