Process and equipment for preparing marsh gas by solid fermentation

A technology of solid-state fermentation and fermentation device, which is applied in the fields of agricultural bioenergy utilization and agricultural biogas preparation, can solve the problems of high concentration of soluble COD in biogas slurry, large reactor volume and intractable treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

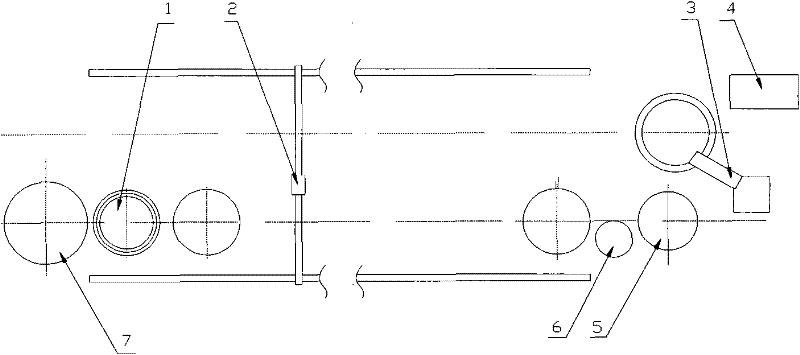

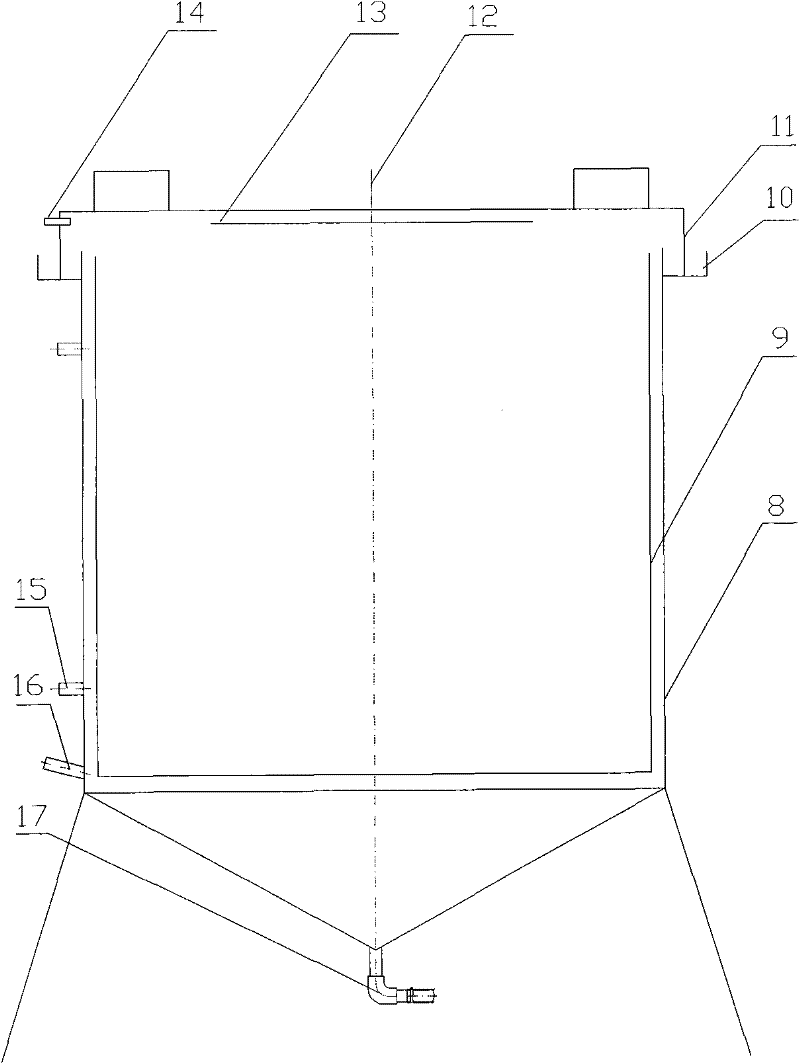

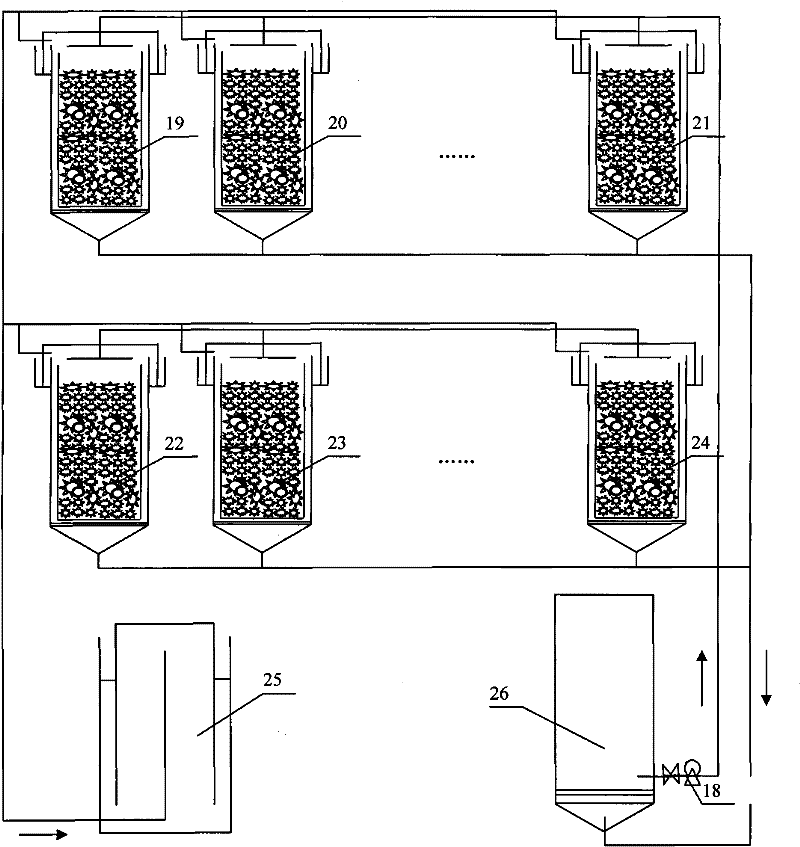

Method used

Image

Examples

Embodiment Construction

[0024] The specific design of this embodiment refers to the technical solutions described in the above-mentioned "Summary of the Invention" and "Description of Drawings". To save space, this paragraph will not repeat the above-mentioned disclosed technical details.

[0025] Process step of the present invention is as follows

[0026] 1) According to the breeding scale of livestock and poultry farms, estimate the amount of feces discharged daily, and measure the moisture content and carbon-nitrogen ratio of feces according to conventional methods;

[0027] 2) Determine the type of crop straw to be added as a conditioning agent. Generally, straw, wheat straw, rape stalk, corn stalk and other crop straws can be selected, or grass and leaves, etc., and the moisture content should be measured according to conventional methods before use and carbon-nitrogen ratio;

[0028] 3) According to the carbon-nitrogen ratio of fermentation raw materials is 20 to 30, the optimal value is 25, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com