A kind of preparation method of boron nitride phosphor material

A phosphor and oxide technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high price, harsh environment, unsuitable for large-scale industrial production, etc., and achieve low cost, short production cycle, and cheap raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1, LiSr 4 (BN 2 ) 3 : Preparation of Cel mol%

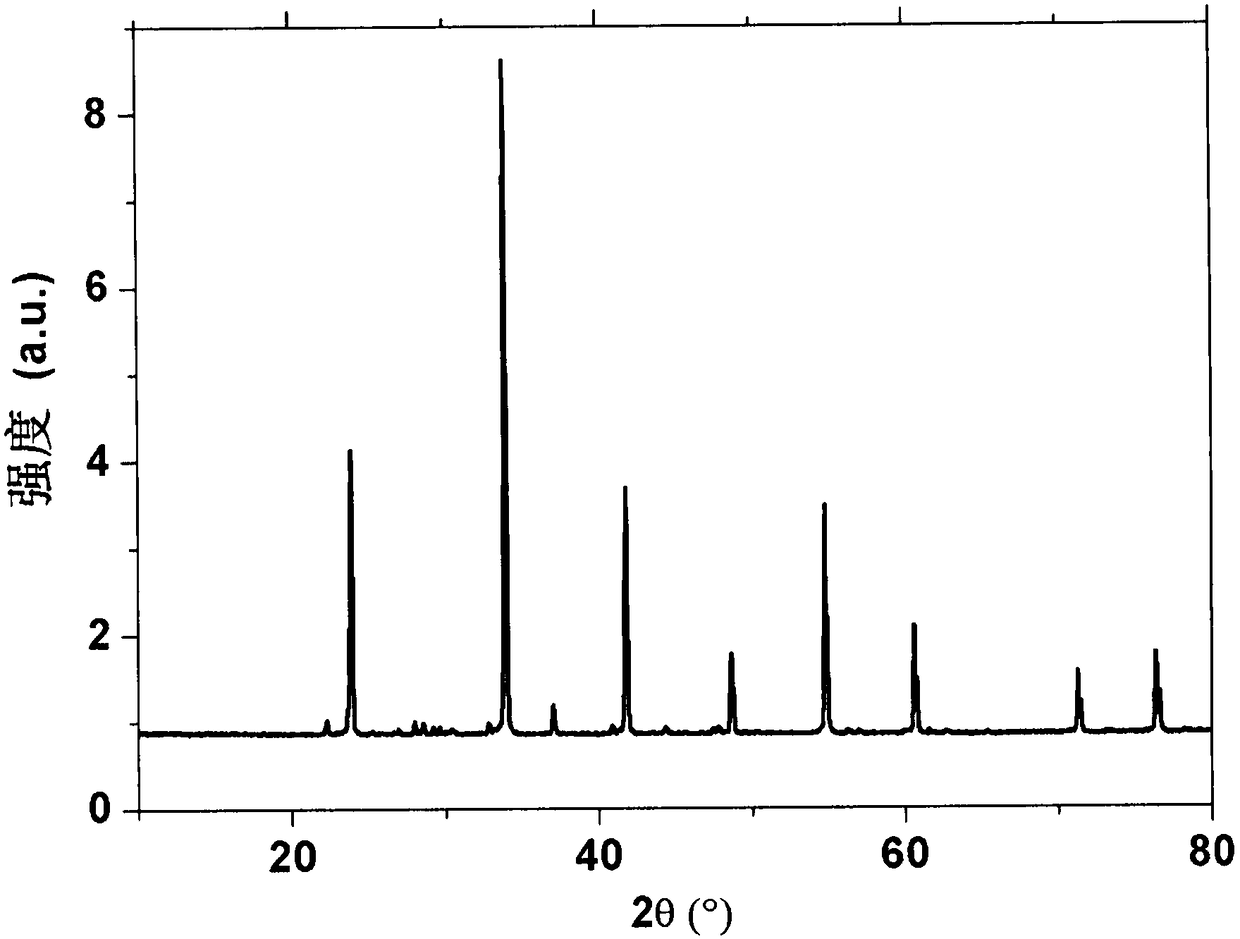

[0048] Weigh 0.185g Li according to the stoichiometric ratio 2 CO 3 , 4.190g Sr(NO 3 ) 2 , 0.927g HBO 3 , 0.035gCeO 2 . Put the weighed raw materials into the agate mortar, add acetone and keep grinding until the acetone is completely evaporated, and all the raw materials are mixed evenly. The mixture was then put into a corundum crucible and sintered at 650°C for 3 hours under charcoal heat. The obtained sintered material was re-ground evenly, then put into a corundum crucible, and sintered at 800°C for 3 hours under charcoal heating conditions, and LiSr was obtained after grinding. 4 (BN 2 ) 3 : Cel mol% phosphor. XRD powder diffraction shows that the obtained is pure LiSr 4 (BN 2 ) 3 structure( figure 1 ).

Embodiment 2

[0049] Example 2, LiSr 4 (BN 2 ) 3 : Preparation of Ce2mol%

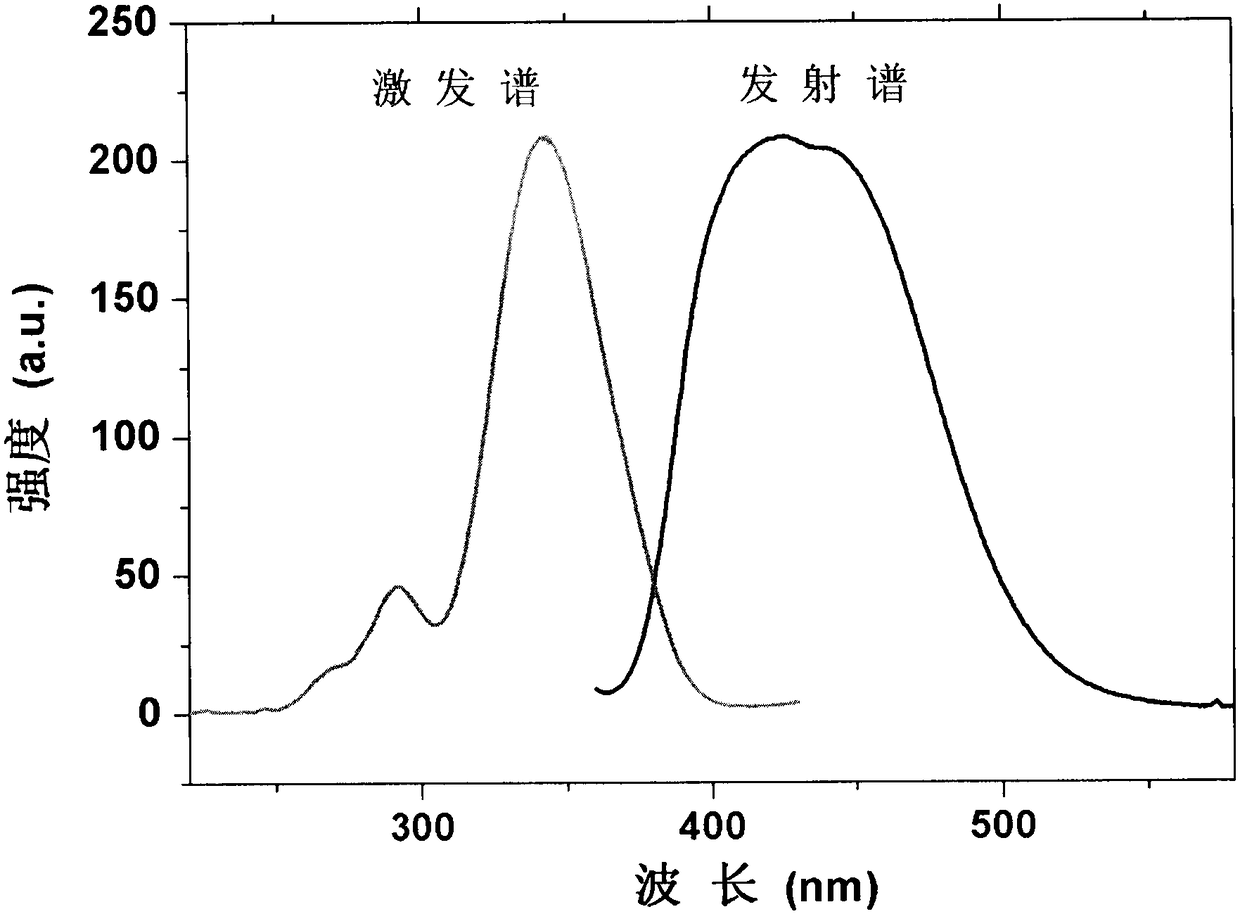

[0050] Weigh 0.185g Li according to the stoichiometric ratio 2 CO 3 , 4.146g Sr(NO 3 ) 2 , 0.927g HBO 3 , 0.069gCeO 2 . Put the weighed raw materials into the agate mortar, add acetone and keep grinding until the acetone is completely evaporated, and all the raw materials are mixed evenly. The mixture was then put into a corundum crucible and sintered at 650°C for 3 hours under charcoal heat. The obtained sintered material was re-ground evenly, then put into a corundum crucible, and sintered at 800°C for 3 hours under charcoal heating conditions, and LiSr was obtained after grinding. 4 (BN 2 ) 3 : Ce2mol% phosphor. Measure the excitation and emission spectra of phosphors with a fluorescence spectrometer, such as figure 2 shown. Under the excitation of near-ultraviolet light, the phosphor exhibits strong blue light emission.

Embodiment 3

[0051] Example 3, LiSr 4 (BN 2 ) 3 : Preparation of Ce 0.5mol%, Tb2mol%

[0052] Weigh 0.185g Li according to the stoichiometric ratio 2 CO 3 , 4.169g Sr(NO 3 ) 2 , 0.927g HBO 3 , 0.017gCeO 2 , 0.083g Tb(NO 3 ) 3 4(H 2 O). Put the weighed raw materials into the agate mortar, add acetone and keep grinding until the acetone is completely evaporated, and all the raw materials are mixed evenly. The mixture was then put into a corundum crucible and sintered at 650°C for 3 hours under charcoal heat. The obtained sintered material was re-ground evenly, then put into a corundum crucible, and sintered at 800°C for 3 hours under charcoal heating conditions, and LiSr was obtained after grinding. 4 (BN 2 ) 3 : Ce2mol% phosphor. Measure the excitation and emission spectra of phosphors with a fluorescence spectrometer, such as figure 2 shown. Under the excitation of near-ultraviolet light, the phosphor exhibits strong blue light emission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com