Aluminum oxide concentration control method based on aluminum electrolytic cell

A technology of aluminum electrolytic cell and control method, applied in the field of self-adaptive control, which can solve problems such as inapplicability of precise control, large measurement error in data measurement, existence of noise, etc., to achieve accurate and real-time control of input amount, precise control of alumina concentration, The effect of improving test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

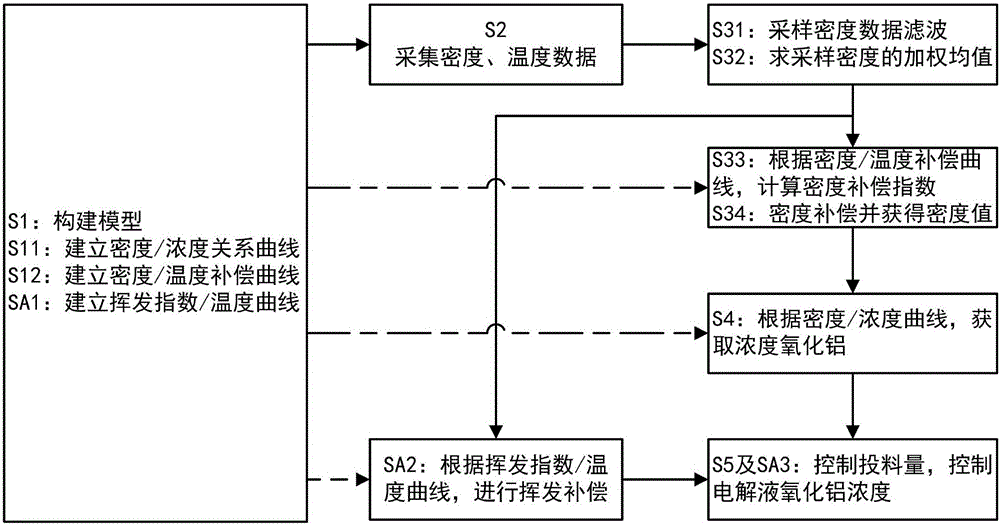

[0038] like figure 1As shown, a method for controlling the concentration of alumina based on an aluminum electrolytic cell provided in this embodiment includes the following steps:

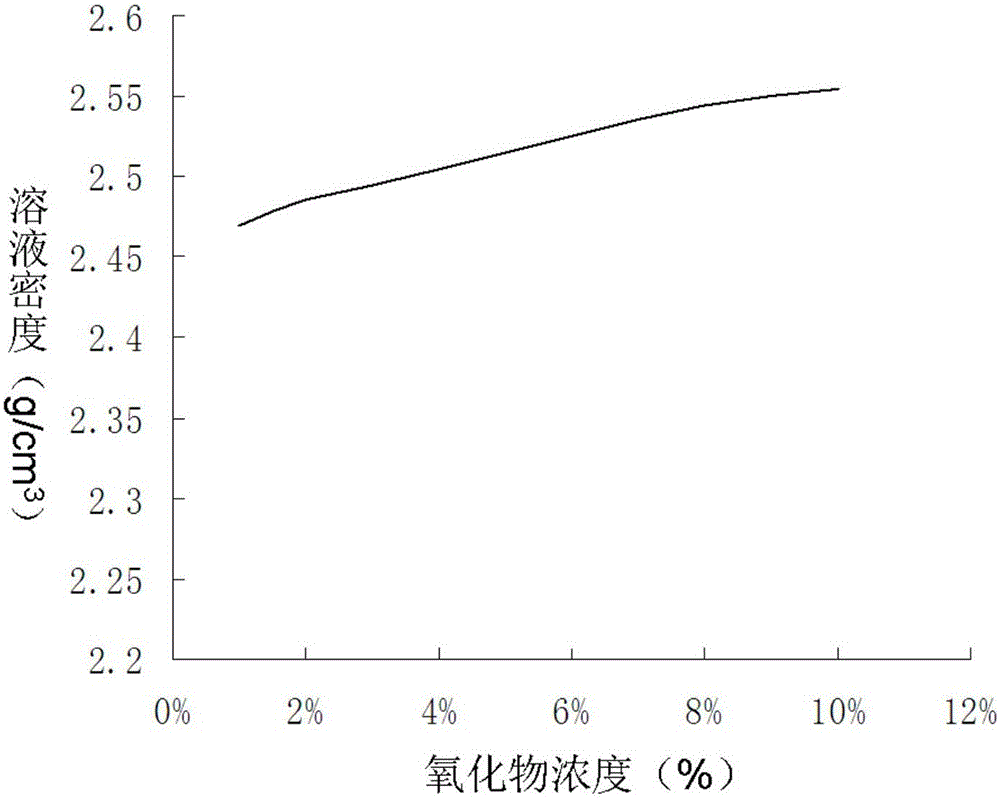

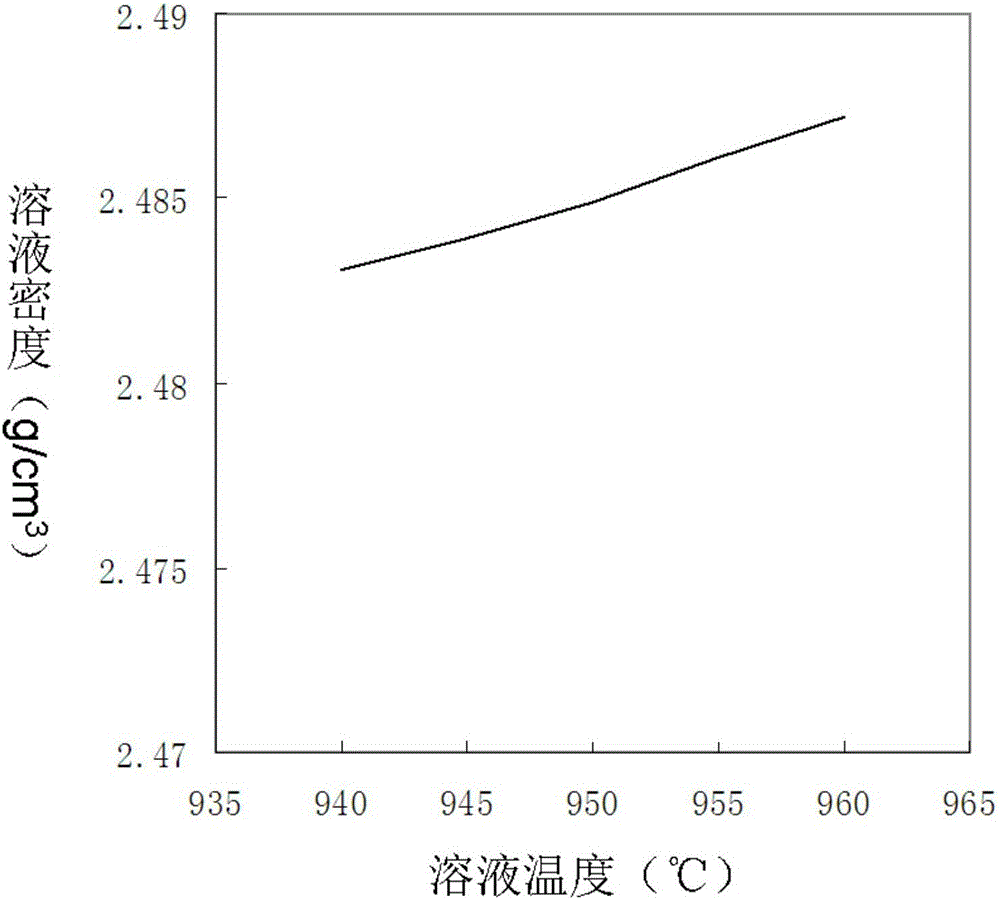

[0039] S1: Model establishment; model establishment includes: S11 establishes the electrolyte density / concentration relationship curve, S12 establishes the electrolyte density / temperature compensation curve; SA1 establishes the volatilization index / temperature curve;

[0040] S2: The density sensor collects the sampling density of the electrolyte and sends it to the control unit; the temperature sensor collects the sampling temperature of the electrolyte and sends it to the control unit;

[0041] S3: S31 the control unit performs digital filtering on the sampling density to filter out abnormal collection points; S32 calculates the weighted average of the filtered sampling densi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com