Hydraulic crane and underground hydraulic support assembly system using the hydraulic crane

A sliding bracket and hydraulic technology, which is applied in mine roof brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of slow bracket assembly progress, complicated construction procedures, and impact on the construction period, so as to improve construction safety and simplify construction The effect of process and wage saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

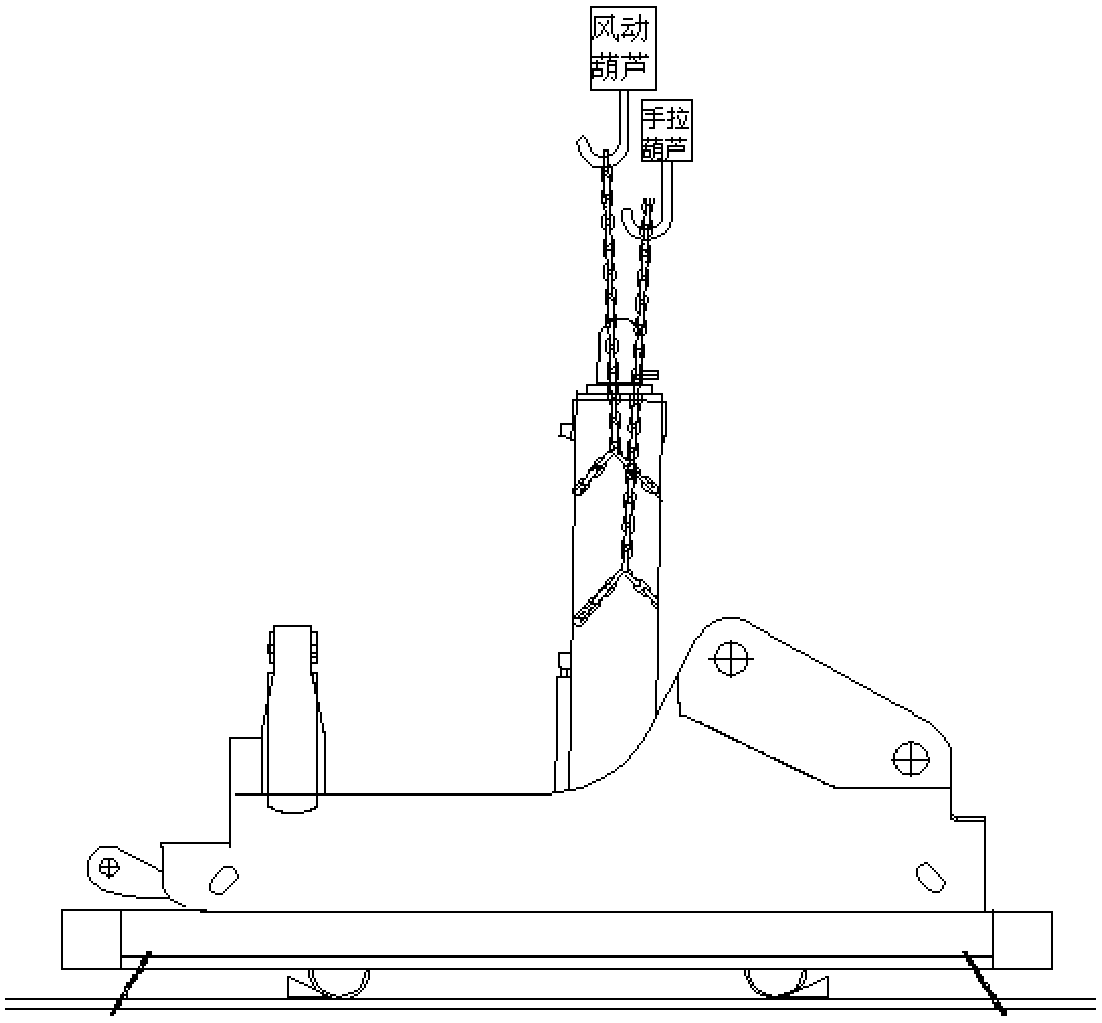

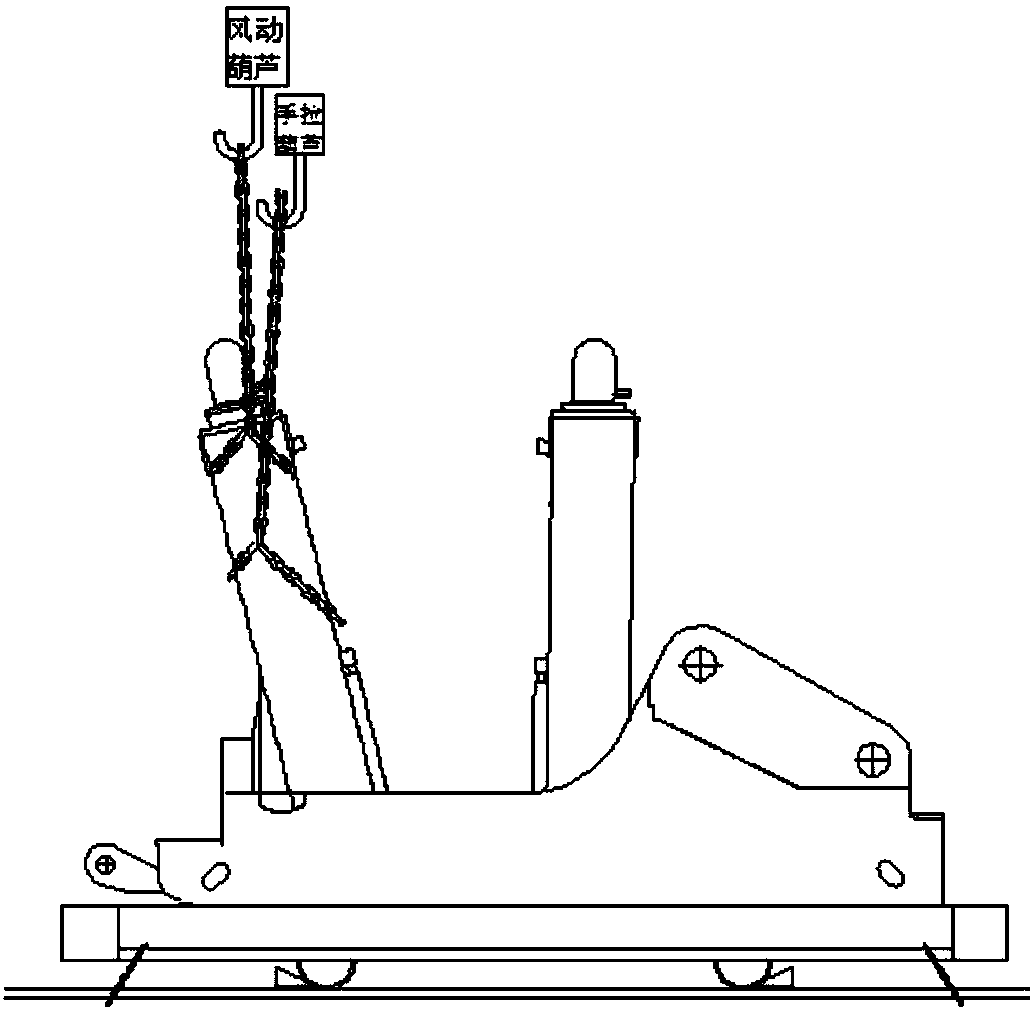

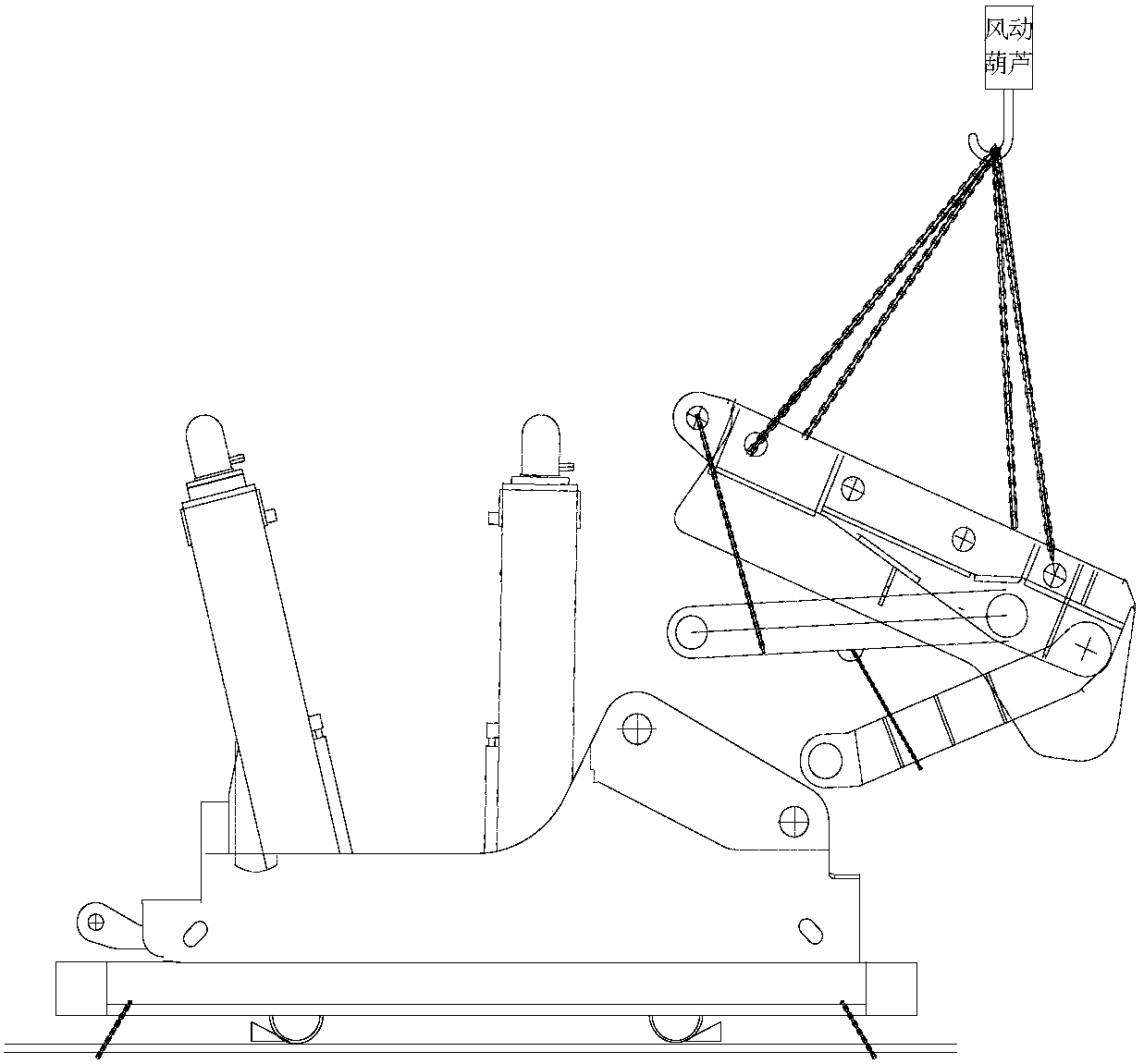

[0035] Such as Figures 5 to 11 As shown, a hydraulic crane includes a fixed bracket, a sliding bracket 12 and a lifting unit, the sliding bracket 12 is slidably arranged on the fixing bracket along the horizontal direction, and the lifting unit is arranged on the sliding bracket 12; the lifting unit Including a sling, a movable pulley 121 and a fixed pulley 122, the axes of the movable pulley 121 and the fixed pulley 122 are all arranged horizontally, and the central planes of the movable pulley 121 and the fixed pulley 122 are located in the same vertical plane; the movable pulley 121 is relative to the sliding bracket 12 is arranged to reciprocate along the horizontal direction perpendicular to its own axis, the fixed pulley 122 is fixed or adjustable relative to the sliding bracket 12, and the fixed pulley 122 is located in the lower space of the movable pulley 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com