Double-wing type power generation device

A power generation device and double-wing technology, which is applied in wind power generation, safety devices, ocean power generation, etc., can solve the problems of ineffective control of blade angle of attack, low energy collection efficiency, and impact on energy efficiency, so as to improve energy capture efficiency and improve energy efficiency. Energy harvesting efficiency and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

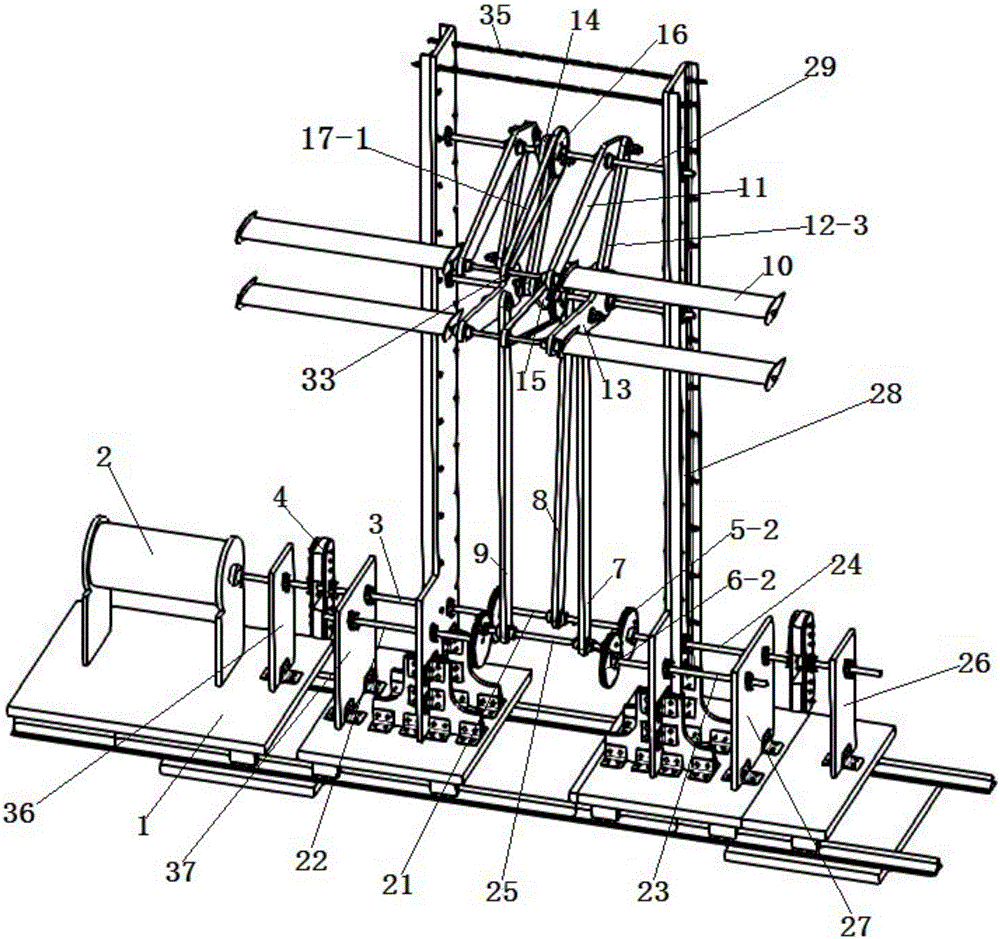

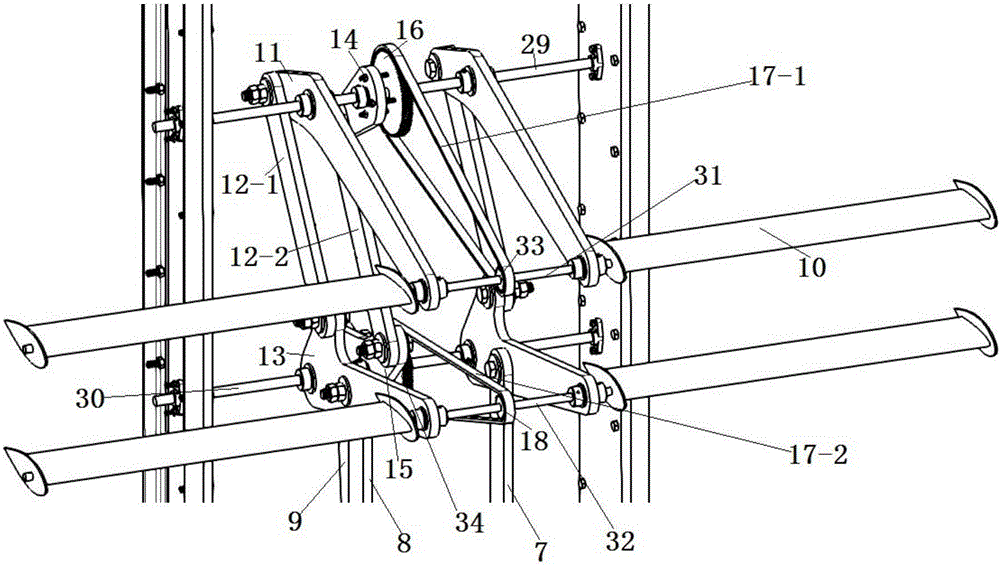

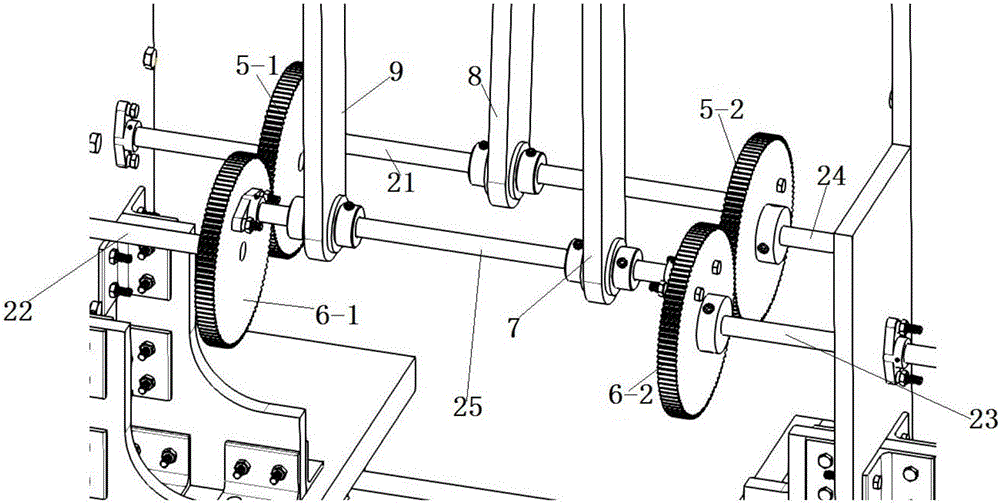

[0020] Example 1: Combining Figure 1 to Figure 3 , two vertical plates 28 are vertically installed on the base 1, and the tops of the two vertical plates 28 are connected by connecting rods 35, and No. 4 shaft seat 37 and No. three axle seat 36, generator 2 is installed on the end of base 1, and No. two axle seat 27 and No. one axle seat 26 are installed on the base of the right side of right vertical plate, the rotating shaft of generator and main shaft 3 connection, the main shaft 3 is installed on the base through the No. 3 shaft seat 36, the end of the main shaft 3 passes through the No. No. 4 shaft 24 is installed on the 26, and the end of No. 4 shaft 24 passes No. 2 shaft seat 27 and the right side vertical plate and No. 2 main gear 5-2 is installed on the end, and the end face of No. 1 main gear 5-1 No. 1 shaft 21 is arranged between the end face of No. 2 main gear 5-2, and No. 2 shaft 22 is installed on the No. 4 shaft seat 37. The end of No. 2 shaft 22 passes throug...

Embodiment 2

[0025] Embodiment two: based on the above embodiment, combined with figure 1 , On the No. 4 shaft 24 between No. 2 shaft seat 27 and No. 1 shaft seat 26 and on the main shaft between No. 3 shaft seat 36 and No. 4 shaft seat 37, inertia wheel 4 is installed respectively.

Embodiment 3

[0026] Embodiment 3: Based on the above embodiments, the base is installed on the ground to form a double-wing wind power generation device, so as to realize the utilization of wind energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com