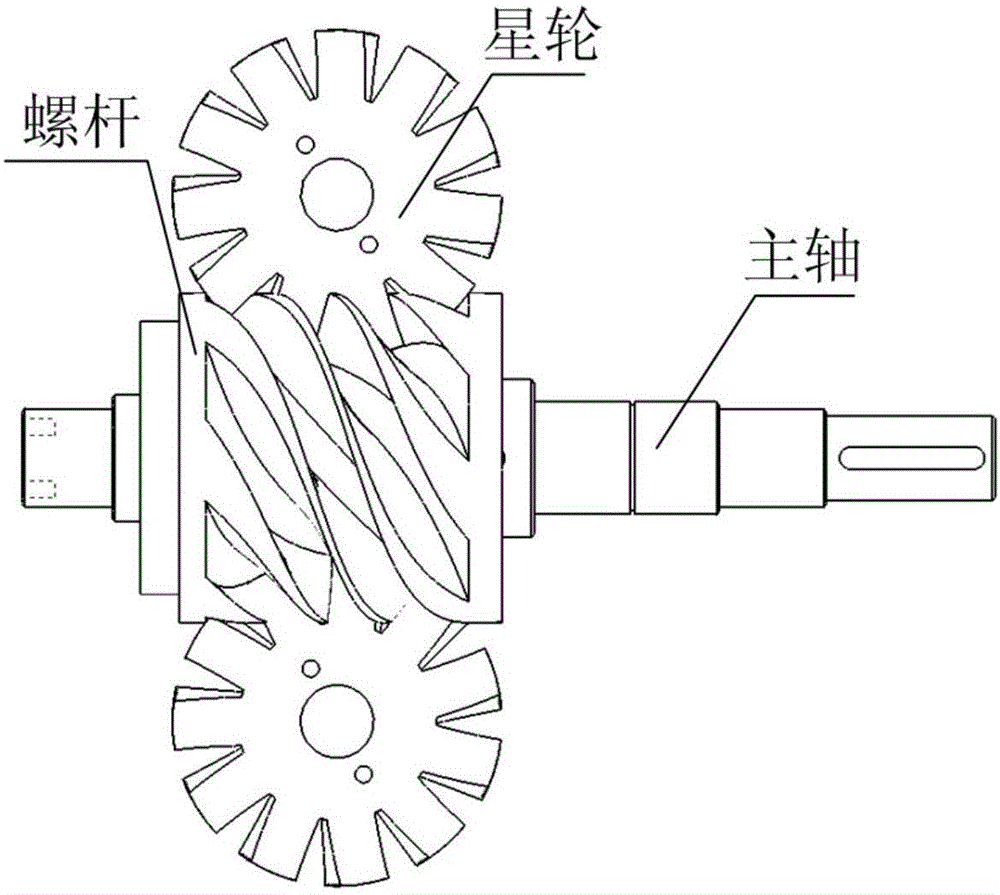

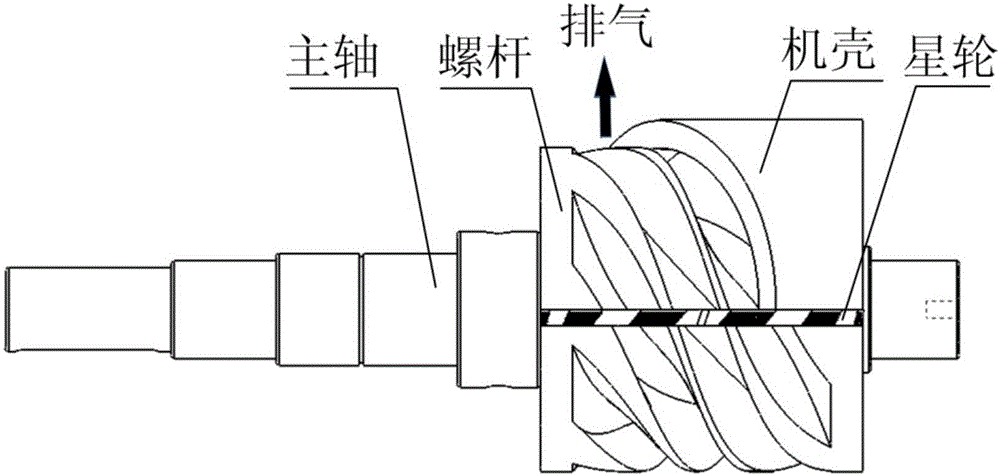

Utilization system for exhaust leaving velocity of spiral grooves of single-screw expansion machine

A single-screw and expander technology, applied in the field of power machinery, can solve the problems of consumption of expansion work, increase of exhaust push work of expander, increase of gas pressure, etc., and achieve the effect of reducing under-expansion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

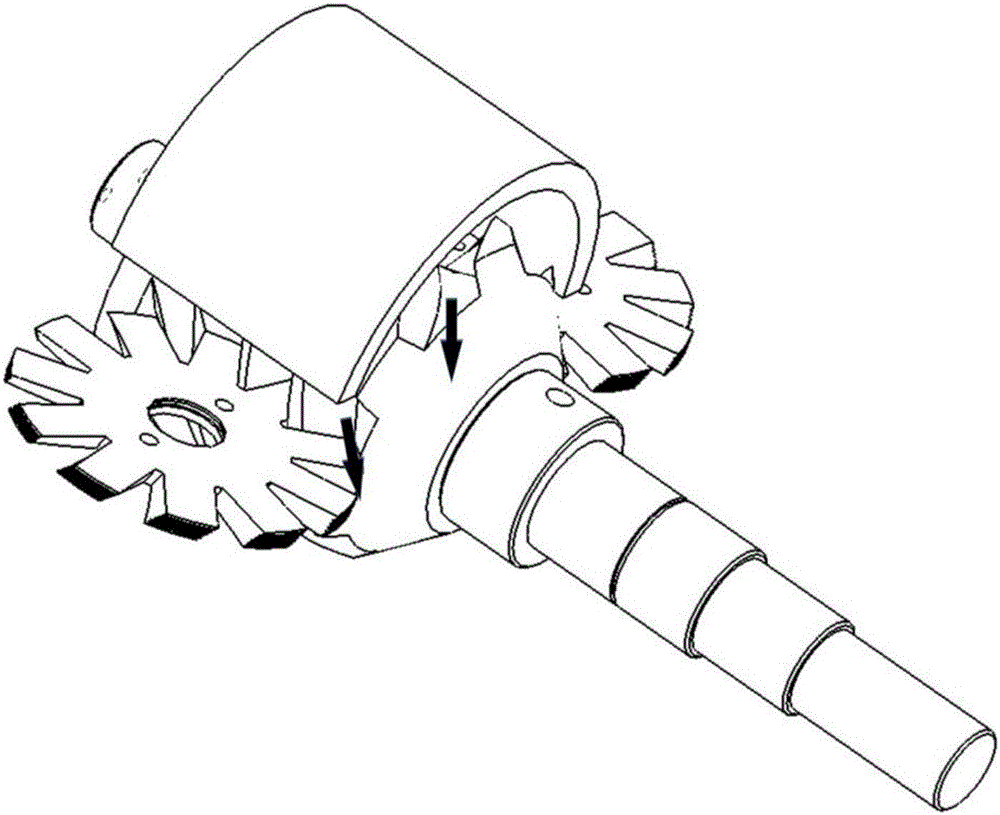

Embodiment 1

[0021] Embodiment 1: The key to implementing the present invention is the position and shape of the gas discharge channel in the screw groove. First of all, on the shell of the single-screw expander, there is no longer a gap for radial exhaust; at the same time, a corresponding exhaust channel is cut out at the tail (low pressure side) of the screw. Example 1 gives a simple way to chamfer the tail of the screw (such as Figure 4 As shown), there is a gap in the screw groove at this time, and the gap is the only channel for the gas in each screw groove to discharge. When the gas is exhausted through this channel, the corresponding speed effect can push the screw to rotate and recover part of the pressure potential energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com