Compound vibration isolating device based on air spring and particle damping material

An air spring and particle damping technology, which is applied in the direction of shock absorber-spring combination, spring, spring/shock absorber, etc., can solve the problems of difficult vibration isolation effect and vibration amplification, and improve the frequency range of vibration isolation , Suppress the resonance peak and improve the effect of vibration isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

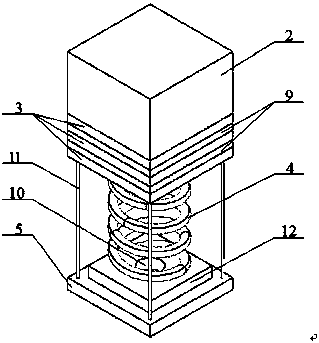

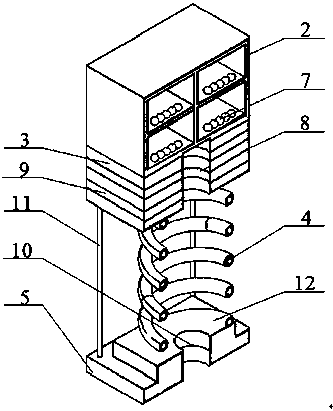

[0035] Such as Figure 1~9 As shown, the present invention is a composite vibration isolation device based on an air spring and a granular damping material, including an air injection hole 1, a helical steel spring 2, a damping particle storage chamber 3, an orifice 4, a bolt hole 5, a top plate 6, Airbag layer 7, steel ball 8 wrapped with soft rubber, air spring chamber 9, base plate 10, steel ring sheet 11.

[0036] First, several rectangular steel plates are welded into 4 chambers, and then the walls of each chamber are bonded with rubber layers, and steel balls 8 wrapped with soft rubber are put in, and then a rectangular plate is welded through fillet welds in the forward direction of the section to form damping Particle storage chamber 3, the particle storage chamber 3 is a cuboid structure, and then 2 through holes are punched on the surrounding four surfaces (front, back, left and right), and the through holes are throttling holes 4 .

[0037] The bottom of the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com