High-efficiency centralized air inducing and distributing system for modular furnace

A technology of centralized induced air and air distribution system, applied in the directions of induced air, combustion method, indirect carbon dioxide emission reduction, etc., can solve the problem that the air equalization effect of the condensation waste heat recovery device cannot reach the ideal effect, and the air equalization effect of the main heat exchanger is unfavorable. Affecting and affecting the thermal efficiency of gas modular furnaces, etc., to achieve the effect of improving air uniformity, benefiting thermal efficiency, and improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

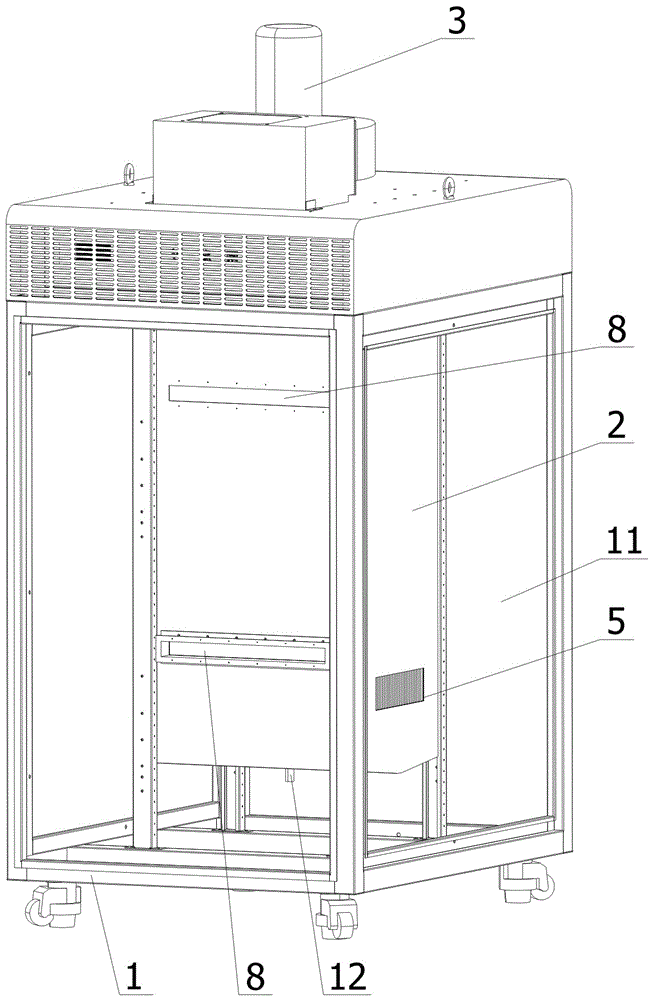

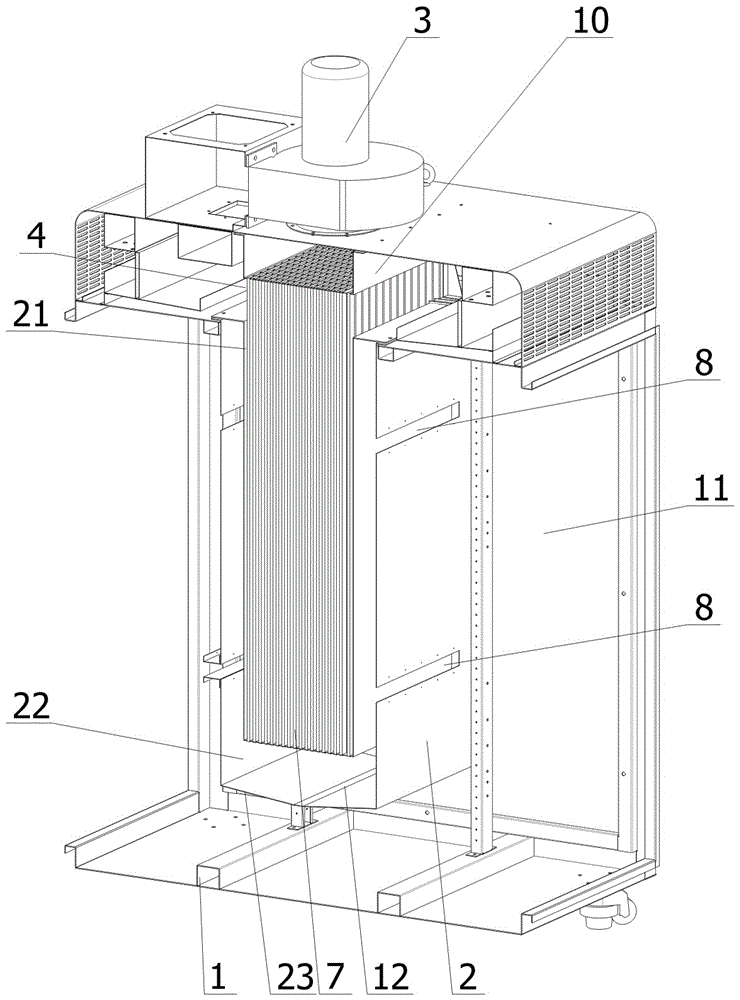

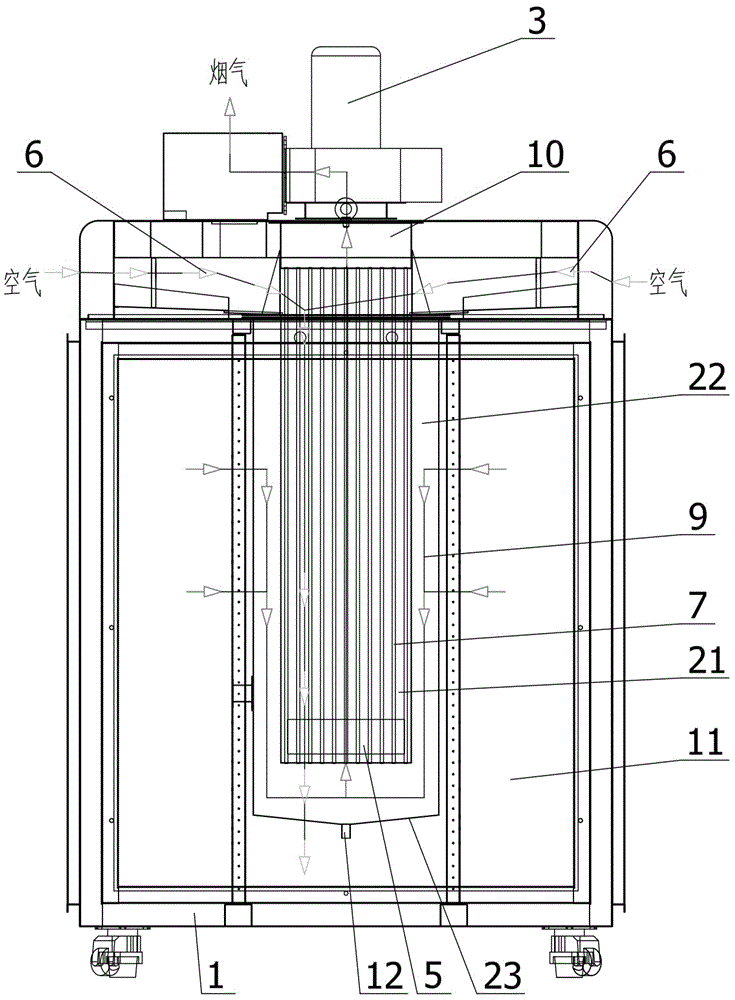

[0019] According to attached figure 1 to attach image 3 As shown, the high-efficiency centralized air induction and air distribution system for modular furnaces of the present invention includes a furnace shell 1 with an inner cavity 11, and the inner cavity 11 is equipped with a smoke exhaust pipe 2 and several gas modules. Wherein, a three-phase fan 3 is arranged above the furnace shell 1 , and a condensation chamber 21 and a smoke exhaust chamber 22 are arranged on the smoke exhaust pipe 2 . The upper end of the condensation chamber 21 is provided with an air inlet 4, and the lower end of the condensation chamber 21 and the lower end of the smoke exhaust chamber 22 are respectively provided with an air outlet 5 communicating with the inner chamber 11, and the air outlets 5 are respectively arranged in the condensation chamber 21 and the lower end of the front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com