Finite amplitude technology-based metal block closed crack detecting and positioning method

A positioning method and a technology of metal blocks, which are applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as the inability to achieve quantitative evaluation and precise positioning of micro-cracks, Achieve the effect of improving the probability of crack detection and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

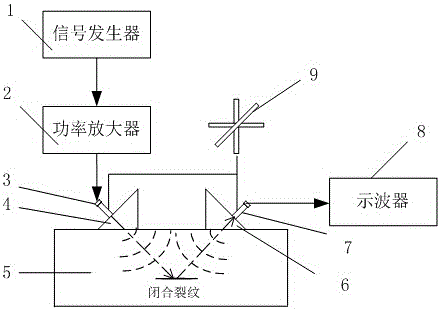

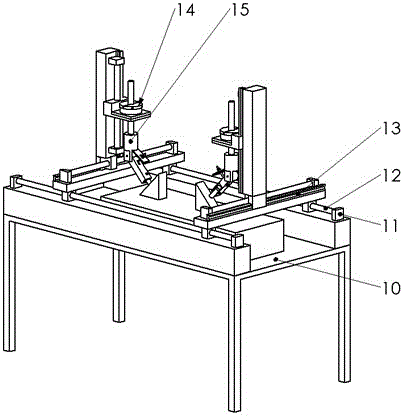

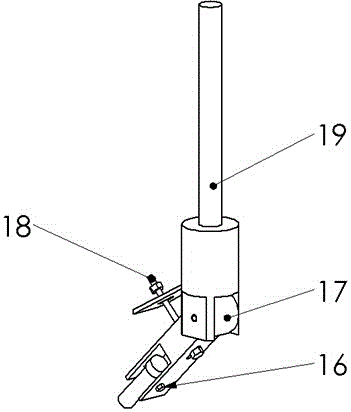

[0044] Taking an aluminum block with a length of 500mm, a width of 250mm and a height of 300mm, with artificially-made closed cracks in the middle as the detection object, according to figure 1 , figure 2Build a detection system. The system includes a signal generator, a power amplifier, an ultrasonic transducer 1, an ultrasonic transducer 2, a wedge block 1, a wedge block 2, and a three-dimensional precision motion control system. The center frequency of the transmitting ultrasonic transducer is 1.39MHz. Due to the interaction between the ultrasonic wave of frequency f and the defect, high-order harmonics of frequency nf (n=1, 2, 3...) will be generated. Therefore, choose a receiving ultrasonic transducer with a larger center frequency and bandwidth. A sine wave with a frequency of 1.4MHz and a voltage of 5V is generated by the signal generator, and the transducer is stimulated to generate large-amplitude ultrasonic waves after being amplified by a power amplifier of 20dB....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com