Treatment apparatus

A technology for processing devices and processing chambers, which is applied in the manufacture of discharge tubes, electrical components, semiconductors/solid-state devices, etc., can solve the problem that heat dissipation measures cannot be applied to large processing containers, achieve good temperature control efficiency, and improve temperature regulation efficiency , The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

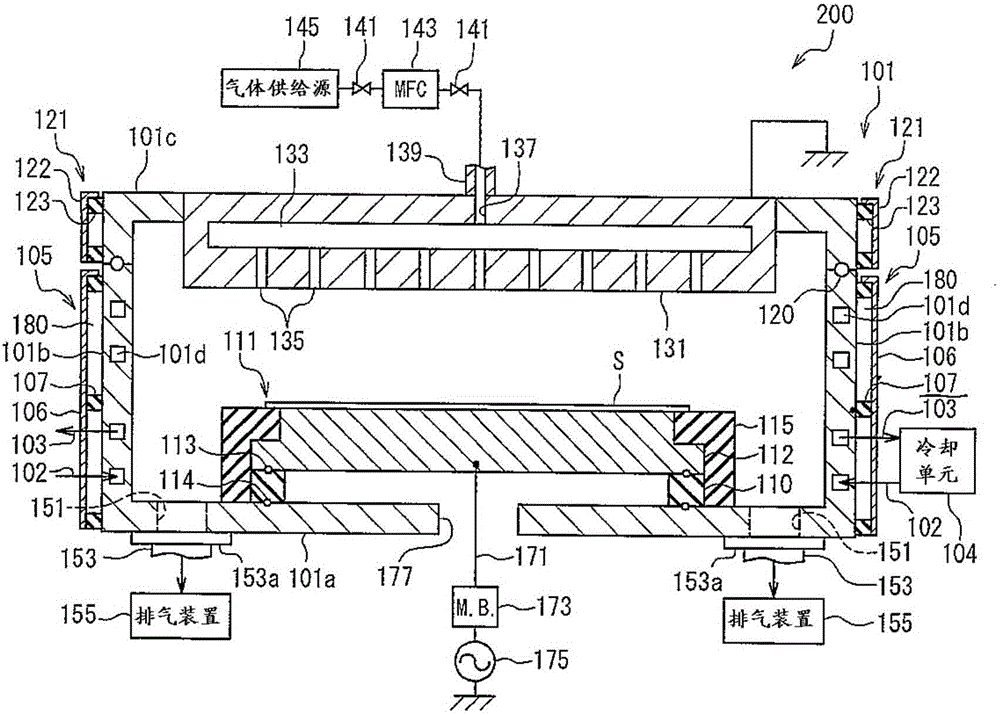

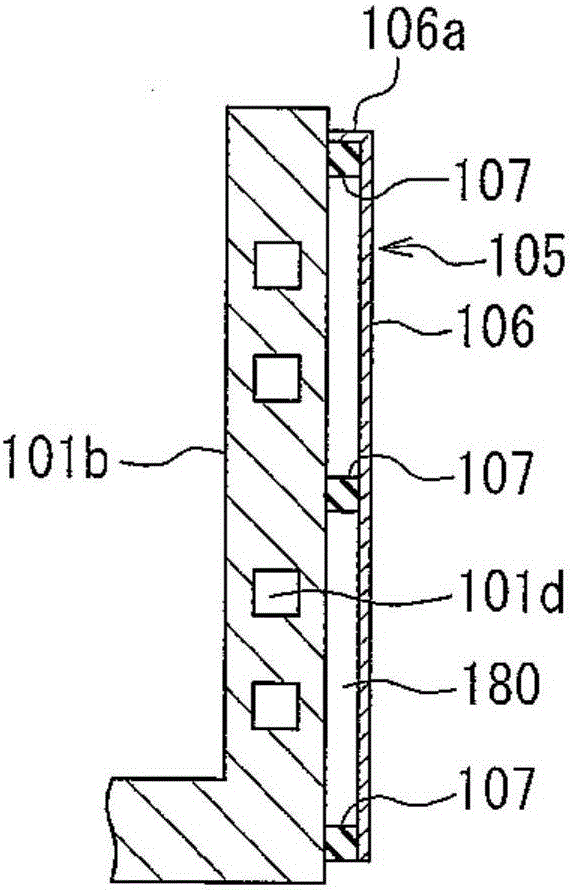

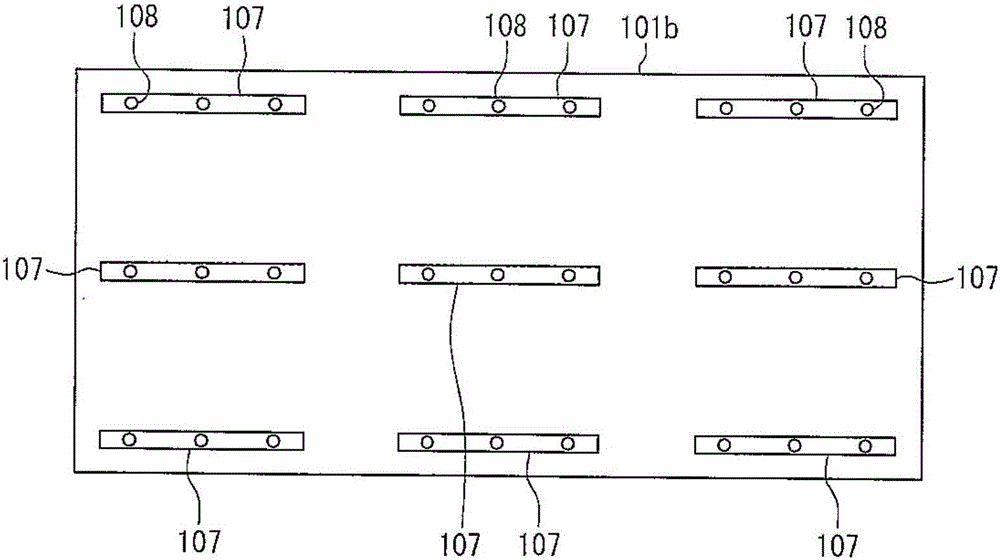

[0034] figure 1 It is a cross-sectional view showing a schematic configuration of a plasma etching apparatus which is a first embodiment of the processing apparatus of the present invention. figure 2 is enlarged figure 1 Sectional view of the main part. Such as figure 1 As shown, the plasma etching apparatus 200 is configured as a capacity-coupled parallel plate plasma etching apparatus that etches, for example, a glass substrate (hereinafter, simply referred to as "substrate'") S for an FPD as an object to be processed. In addition, examples of the FPD include a liquid crystal display (LCD), an electroluminescence (Electro Luminescence; EL) display, a plasma display panel (PDP), and the like.

[0035] This plasma etching apparatus 200 has a processing container 101 formed in a square tube shape made of aluminum whose inside is anodized (aluminum anodized). The main body (container body) of the processing container 101 is composed of a bottom wall 101a and four side walls...

no. 2 approach

[0069] Next, refer to Figure 10 A plasma etching apparatus according to a second embodiment of the processing apparatus of the present invention will be described. Figure 10 is an enlarged representation of the first embodiment with figure 2 Corresponding drawings of the cross section of the main part of the processing container 101. In addition, in the following description, the difference from the first embodiment will be mainly described, and the description of the same configuration as the first embodiment in the second embodiment will be omitted.

[0070] Such as Figure 10 As shown, the heat dissipation suppressing unit 201 of the plasma etching apparatus of this embodiment includes an inner plate 202 close to the side wall 101 b and an outer plate 203 disposed outside the inner plate 202 . Thereby, the air heat insulation part becomes the double heat insulation structure of the inner heat insulation part 180a and the outer heat insulation part 180b. The inner hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com