Composite filter stick wound with spice-containing threads and preparation method of composite filter stick

A technology of composite filter rods and production methods, which is applied in the fields of e-liquid filter elements, food science, applications, etc., can solve the problems of huge tax losses of national interests, endanger the normal development of the cigarette industry, and damage the legitimate rights and interests of consumers. Loss of interests, simplified material preparation and warehousing and logistics links, convenient and intuitive comparison and distinction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

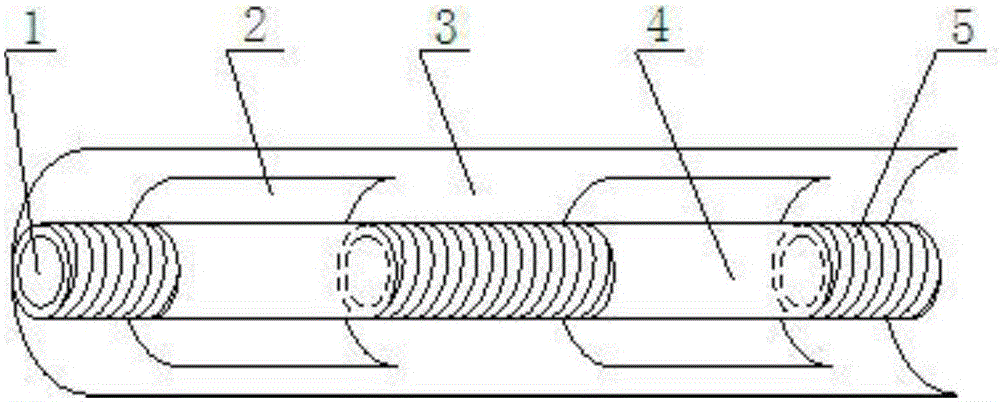

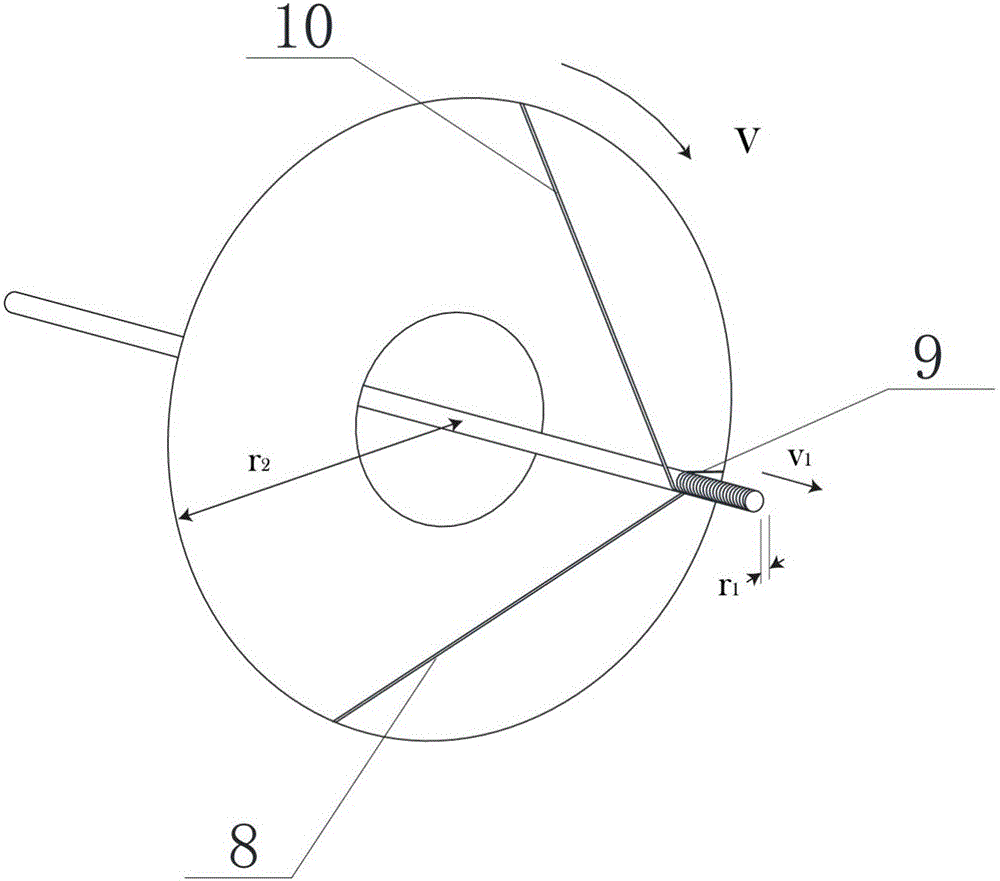

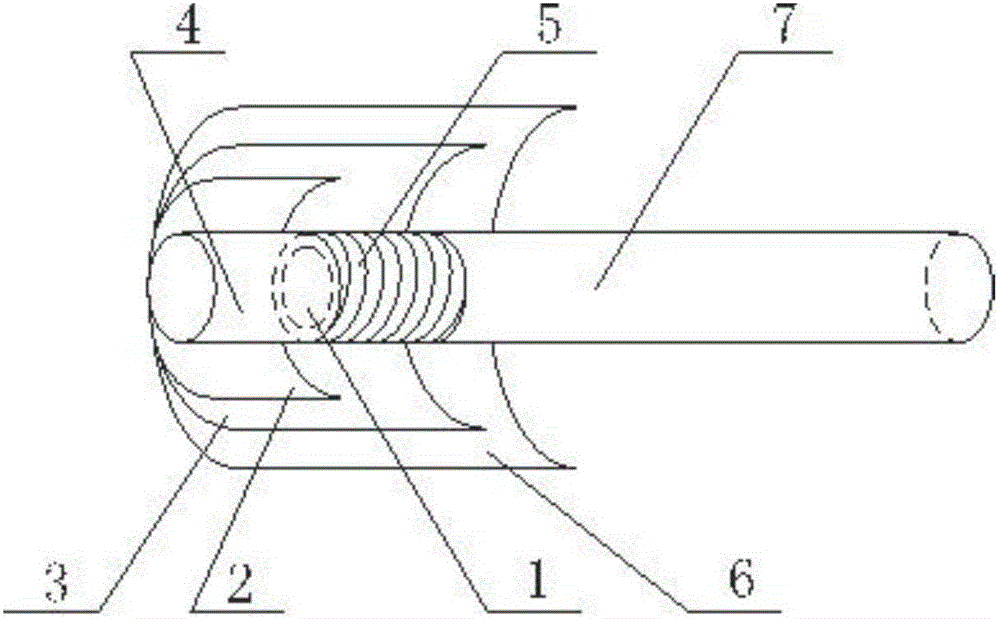

[0028] Embodiment 1: input relevant parameters: filter rod circumference 16.8mm (being core rod radius r 1 =2.67mm), the number of spice threads n=3, the axial displacement velocity v of mandrel 1 =50m / min, the radius of spice wire winding disc r 2 =30mm, the diameter d=0.5mm of the spice thread, and calculated according to the mathematical model: the outer wall linear velocity V=4712.4m / min of the spice thread winding reel, the winding angle α=1.477 degrees of the spice thread, and other key parameters.

[0029] At the same time, different spices are applied to multiple cotton threads respectively to make spice threads for later use;

[0030] Secondly, the acetate fiber is opened, and a plasticizer is applied to the acetate fiber to produce an acetate core rod;

[0031] In the third step, after sizing the spice line, process parameters calculated according to the mathematical model: the outer wall linear velocity of the spice line winding reel V = 4712.4m / min, the winding a...

Embodiment 2

[0038] Embodiment 2: input related parameters: filter rod circumference 23.6mm (i.e. core rod radius r 1 =3.76mm), the number of spice threads n=2, the axial displacement velocity of mandrel v 1 =50m / min, the radius of spice wire winding disc r 2 =30mm, the diameter d=0.6mm of the spice thread, and according to the mathematical model (formula 1, formula 2, formula 3), solve and calculate: the outer wall linear velocity V=5236m / min of the spice thread winding reel, the winding angle α of the spice thread = 1.491 degrees, and other parameters.

[0039] At the same time, different spices are applied to multiple cotton threads respectively to make spice threads for later use;

[0040] Secondly, the acetate fiber is opened, and a plasticizer is applied to the acetate fiber to produce an acetate core rod;

[0041] In the third step, after sizing the spice line, process parameters calculated according to the mathematical model: the outer wall line speed V of the spice line winding...

Embodiment 3

[0048] Embodiment 3: filter rod circumference 24.0mm (ie core rod radius r 1 =3.82mm), the number of spice threads n=1, the axial displacement velocity v of mandrel 1=50m / min, the radius of spice wire winding disc r 2 =30mm, the diameter d=0.7mm of the spice thread, and according to the mathematical model (formula 1, formula 2, formula 3), solve and calculate: the outer wall linear velocity V=6732m / min of the spice thread winding reel, the winding angle α of the spice thread = 1.479 degrees, and other parameters.

[0049] At the same time, different spices are applied to multiple cotton threads respectively to make spice threads for later use;

[0050] Secondly, the acetate fiber is opened, and a plasticizer is applied to the acetate fiber to produce an acetate core rod;

[0051] In the third step, after sizing the spice line, process parameters calculated according to the mathematical model: the outer wall linear velocity V of the spice line winding reel V = 6732m / min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com