Composite filter drum filter

A filter cartridge filter, filter cartridge technology, applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of low dehydration efficiency, low sludge compaction, damage to equipment, etc., to achieve Increase the efficiency of dehydration, realize automatic control and convenient monitoring, and increase the effect of filtering area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

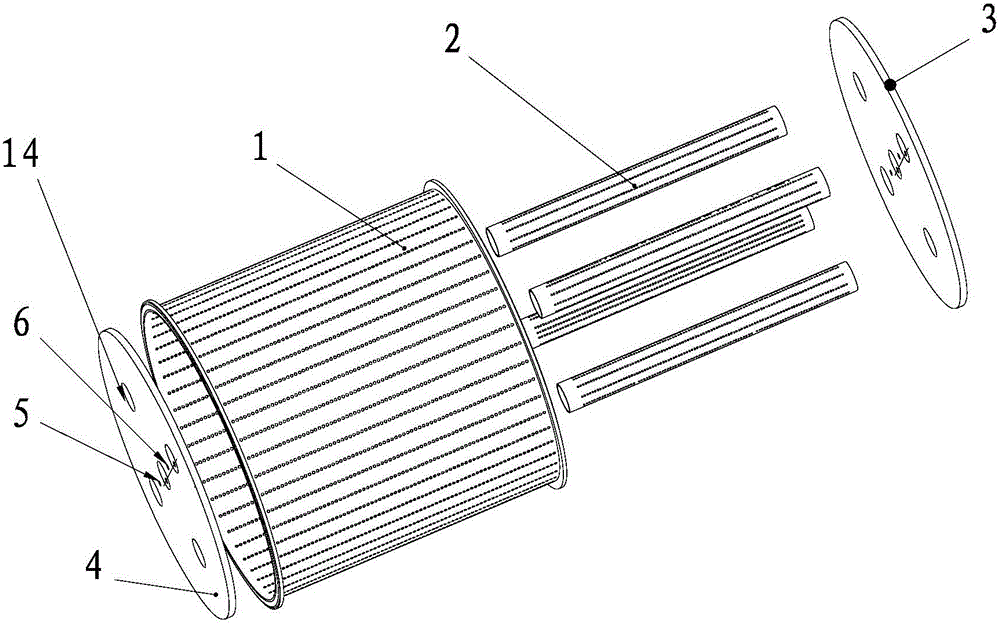

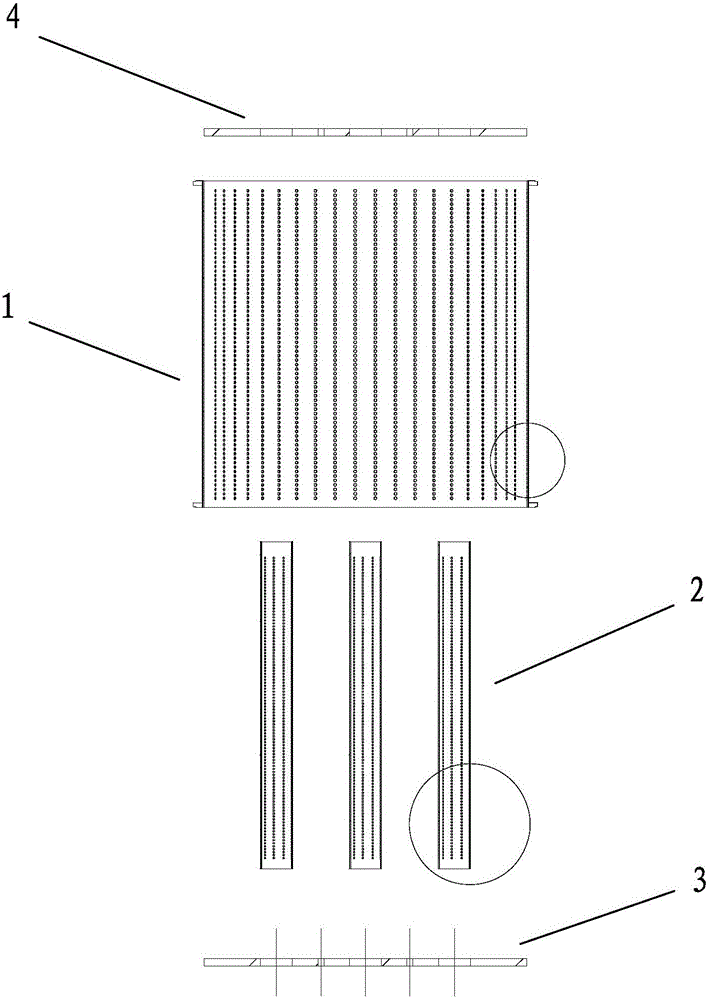

[0035] Such as figure 1 , figure 2 As shown, a composite filter cartridge filter includes a composite filter cartridge 1, four composite filter tubes 2, a first sealing plate 3, and a second sealing plate 4.

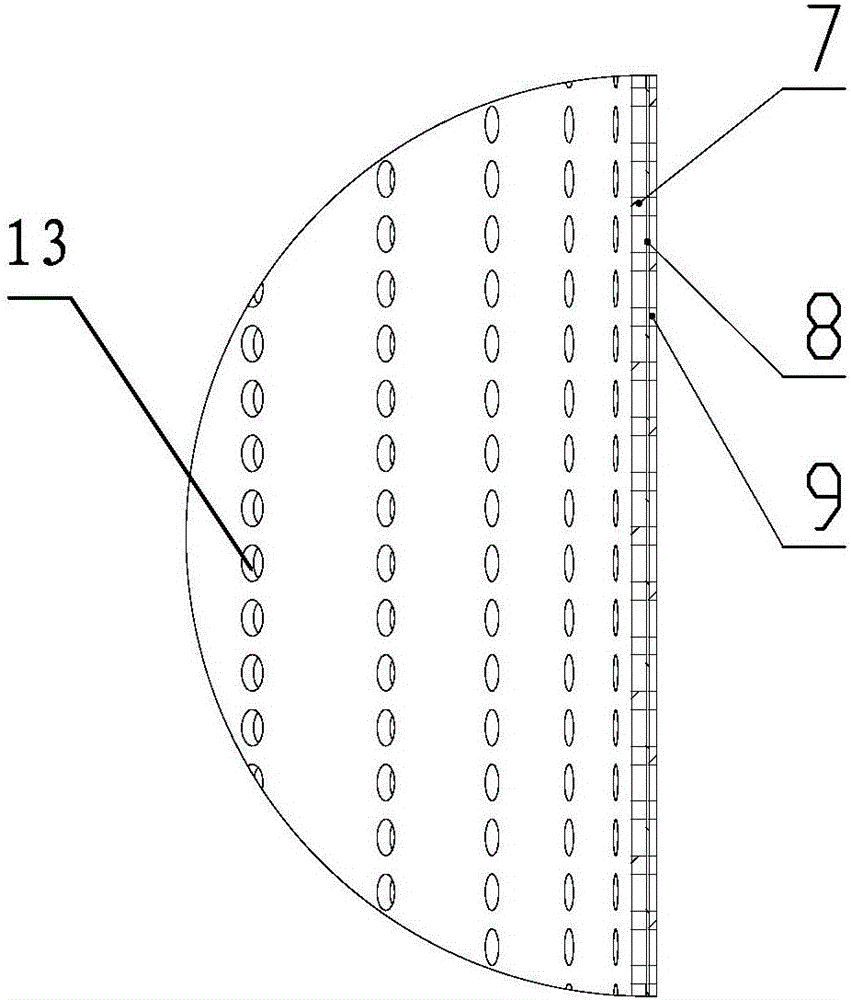

[0036] Both ends of the composite filter cartridge are open, such as image 3 As shown, the cylinder wall of the composite filter cartridge includes a filter cartridge inner orifice plate 7, a filter cartridge filter layer 8 and a filter cartridge outer orifice plate 9 from the inside to the outside, and the filter cartridge inner orifice plate, the filter cartridge outer orifice plate Filter holes 13 are provided. Wherein the filter cartridge filter layer is a filter screen. The total area of the filter holes on the composite filter cartridge accounts for 50% of the total area of the outer wall of the composite filter cartridge, and the diameter of the filter holes is 3mm.

[0037] Both ends of the composite filter tube are open, such as Figure 4 As shown, th...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the number of composite filter tubes in this embodiment is 6, and the filter layer of the filter cartridge or the filter layer of the filter tube is filter cloth. The total area of the filter holes on the composite filter tube accounts for 60% of the total area of the outer wall of the composite filter tube; and the diameter of the filter holes is 4mm. The total area of the filter holes on the composite filter cartridge accounts for 60% of the total area of the outer wall of the composite filter cartridge, and the diameter of the filter holes is 4mm. And this embodiment is not provided with a pressure sensor and a moisture content sensor.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that the number of composite filter tubes in this embodiment is one. The filter cartridge filter layer or the filter tube filter layer is a filter membrane. The total area of the filter holes on the composite filter tube accounts for 70% of the total area of the outer wall of the composite filter tube; and the diameter of the filter holes is 5mm. The total area of the filter holes on the composite filter cartridge accounts for 70% of the total area of the outer wall of the composite filter cartridge, and the diameter of the filter holes is 5mm. And the pressure sensor and the water content sensor of this embodiment are installed on the first sealing plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com