Printing mechanism of unit type flexo printing machine

A technology for flexographic printing machines and printing mechanisms, applied to printing machines, general parts of printing machinery, rotary printing machines, etc., can solve problems such as inconvenient adjustment of plate roller pressure, and achieve outstanding substantive features, convenient removal, and printing accuracy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

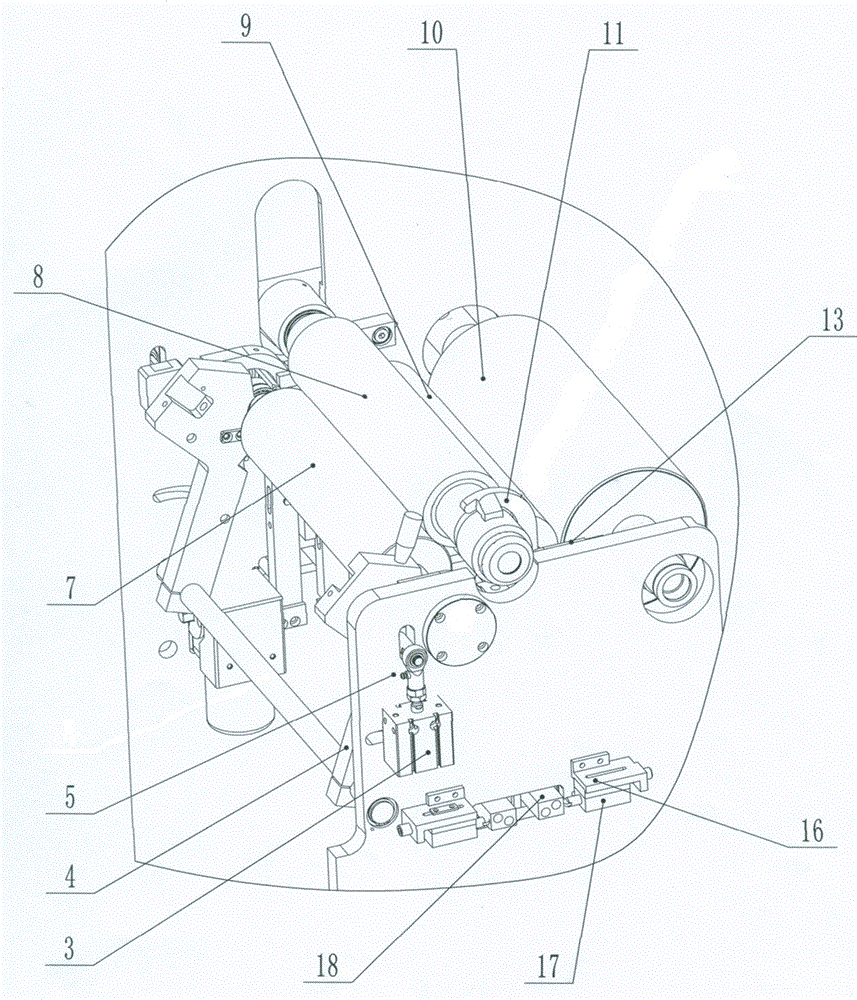

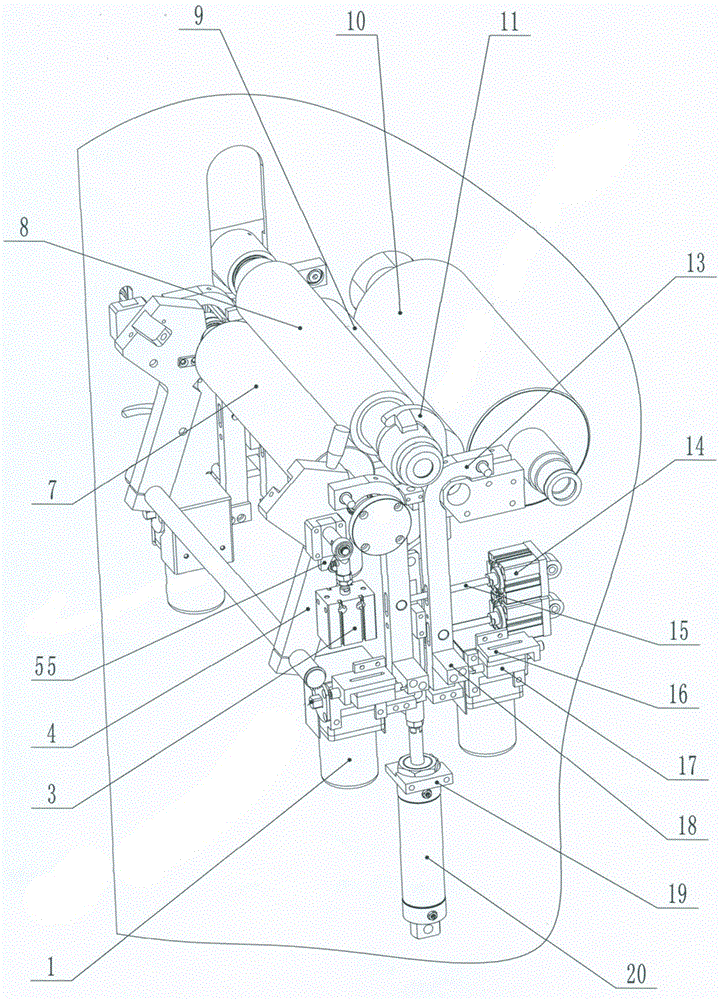

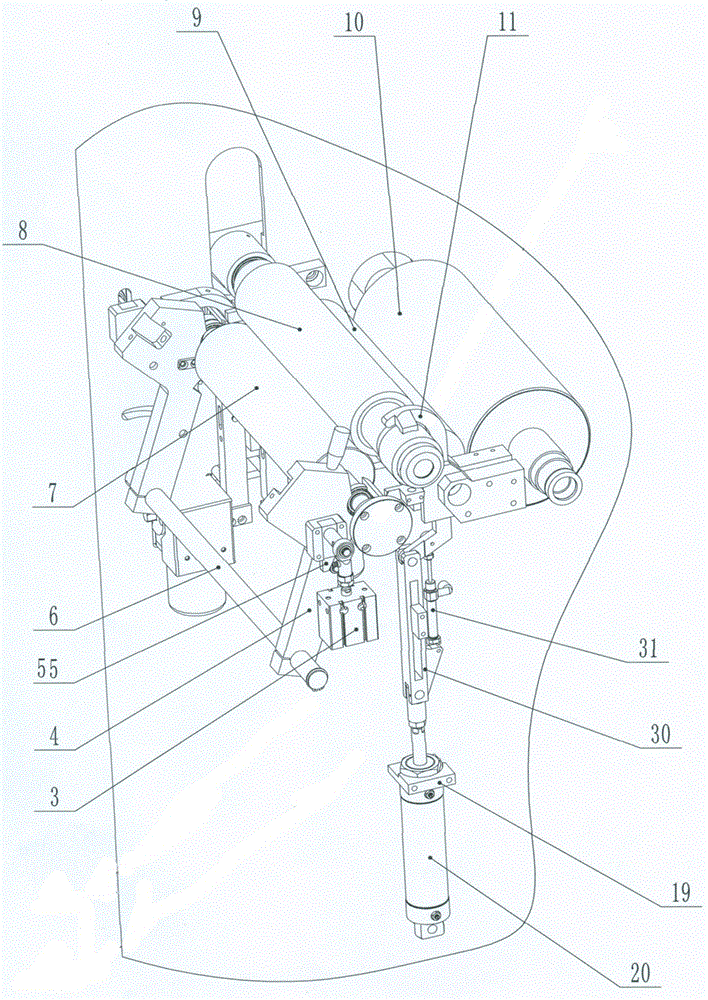

[0020] Referring to the accompanying drawings, the printing mechanism of the group flexographic printing machine in this embodiment is provided with an anilox roller 7, a version roller 8, a bottom roller 10 and a UV assembly on the frame. The UV component includes a curing box, UV lamp and fan, etc. The bottom roller and the UV component work together to complete the curing. The version roller 8 is driven to rotate by the first power source, and the bottom roller 10 is rotated by the second power source, both of the first power source and the second power source include servo motors. The frame is also provided with a passive roller 9, which is located between the anilox roller 7 and the bottom roller 10. Under working conditions, the passive roller 9 cooperates with the version roller 8 to complete printing. The passive roller will be driven by the substrate (such as paper) to rotate. The two work of printing and curing are separated on two rollers, and the passive roller ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com