Vertical sewage treatment tank

A sewage treatment tank, vertical technology, applied in the field of vertical sewage treatment tanks, can solve the problems of pipeline design and loss, reduce space utilization, high energy consumption, etc., achieve small footprint, compact structure, high efficiency The effect of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

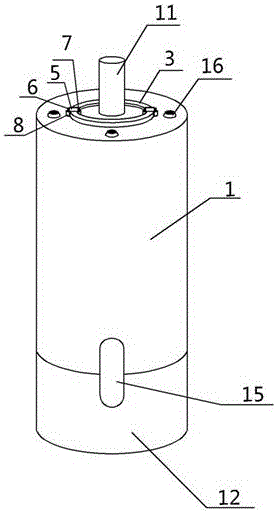

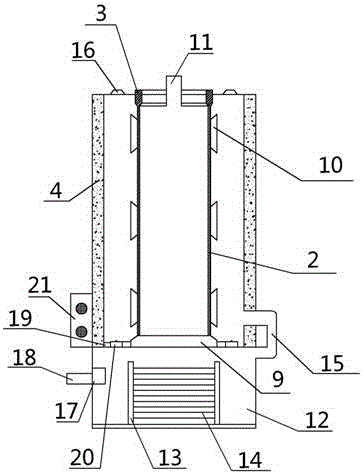

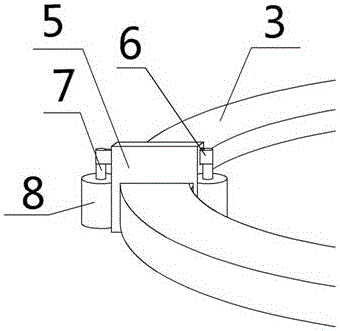

[0023] Such as figure 1 , figure 2 and image 3 Shown is the preferred solution of the present invention, a vertical sewage treatment tank, comprising a tank body 1, the top of the tank body 1 is provided with a track rotation device, and the tank body 1 is provided with a grid layer 2, and the grid layer 2 The upper end is provided with a ring-shaped track 3, and the ring-shaped track 3 passes through the top of the tank body 1 and cooperates with the track rotation device. The bottom of the tank body 1 is also provided with a UV lamp chamber 12; the grid layer 2 is a cylindrical fine grid, which can Particles and suspended solids in the water are filtered out, and the ring-shaped track 3 is driven by the track rotating device, thereby driving the grid layer 2 to rotate circumferentially in the tank body 1, and the sewage treated by the tank body 1 enters the UV lamp chamber Sterilize and disinfect within 12. The principle of ultraviolet disinfection is to use its strong c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com