Fiber rope quick connecting piece and connection method

A fast connection and fiber rope technology, applied in textiles, papermaking, textile cables, etc., can solve the problems of low structural strength of connection nodes, cumbersome operation, and inability to achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

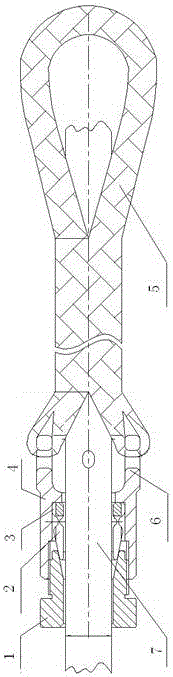

[0025] Take an ultra-high molecular weight polyethylene twelve-strand fiber rope with a diameter of φ24mm as an example. The length of the rope is N meters, the theoretical breaking force is 520KN, and the breaking force with eyelets is 470KN. Make two slings separately, and pull the broken test.

[0026] 1) First, dip-coat the fiber rope with epoxy resin as usual, and cut two sections, each 3.5 meters long, for making fiber rope sleeves.

[0027] 2) Use 65Mn to make a steel sleeve with an inner diameter of φ26mm, quench, deburr, and make it into an elastic fastener, so that the elastic fastener can easily penetrate the fiber rope without burrs.

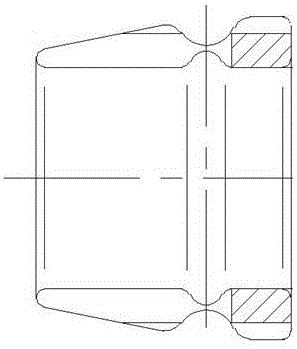

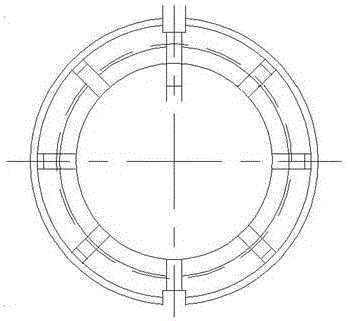

[0028] 3) Make screw fasteners and connectors, the dimensions and connections are as shown in the figure.

[0029] 4) Connect one of the two 3.5-meter-long fiber ropes to a set of quick connectors at both ends, then cut two sections of fiber ropes of sufficient length, insert a fiber rope sleeve each, and insert the other ends into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com