Artificial grass colloidal particle laying and scattering device

A technology of artificial turf and colloidal particles, which is applied in the field of sports equipment, can solve problems such as low spreading efficiency, uneven spreading, and affecting the use of lawns, and achieve the effects of improving spreading efficiency, simple structure, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

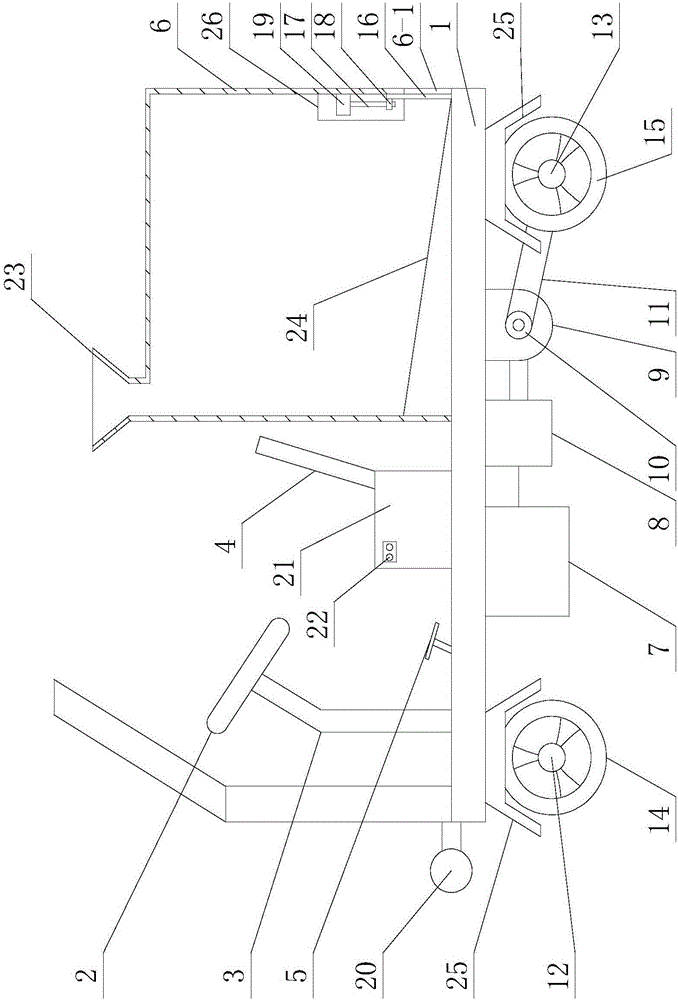

[0015] Specific implementation mode 1: Combination figure 1 To explain this embodiment, the artificial turf rubber particle spreading device described in this embodiment includes a vehicle body 1, a steering wheel 2, a steering assembly 3, a seat 4, a power pedal 5, a brake pedal, a rubber particle storage box 6, and a battery 7. , Drive motor 8, gearbox 9, drive sprocket 10, chain 11, front axle 12, rear axle 13, driven sprocket, two front wheels 14 and two rear wheels 15, steering wheel 2, seat 4, rubber The grain storage box 6 is arranged on the upper surface of the car body 1 from front to back, and the front axle 12, the battery 7, the drive motor 8, the gearbox 9, and the rear axle 13 are installed on the bottom of the car body 1 from front to back. On the surface, two front wheels 14 are sleeved on both ends of the front axle 12, two rear wheels 15 are sleeved on both ends of the rear axle 13, the steering wheel 2 is connected to the front axle 12 through the steering as...

specific Embodiment approach 2

[0016] Specific implementation manner two: combination figure 1 To explain this embodiment, the artificial turf rubber particle spreading device described in this embodiment further includes a baffle 16, a screw 17, a nut 18, and a control motor 19. The baffle 16 is vertically arranged at the rubber particle spreading port 6-1 The nut 18 is installed on the upper end of the inner side of the baffle 16, the control motor 19 is installed on the inner side of the tail of the rubber storage box 6, and the control motor 19 is above the inner side of the rubber sprinkling port 6-1, and the screw 17 The upper end is connected with the rotating shaft of the control motor 19, and the lower end of the screw rod 17 is inserted into the nut 18. The technical effect of the present embodiment is that by setting in this way, the lifting scale of the baffle 16 can be controlled, and thus the spreading rate of the rubber particles can be controlled. The other components and connection relation...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 To explain this embodiment, the lower part of the front end surface of the vehicle body 1 of the artificial turf rubber particle spreading device described in this embodiment is provided with an anti-collision guardrail 20. The technical effect of this embodiment is that such a configuration can effectively prevent the front end of the vehicle body 1 from being damaged. The other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com