Oil drain device

An oil drain and oil drain technology, which is applied in the field of oil drains, can solve the problems of wellhead environmental pollution, sucker rod breakage, wax deposition, affecting the efficiency of workover operations, etc., and achieves the effect of easy use and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

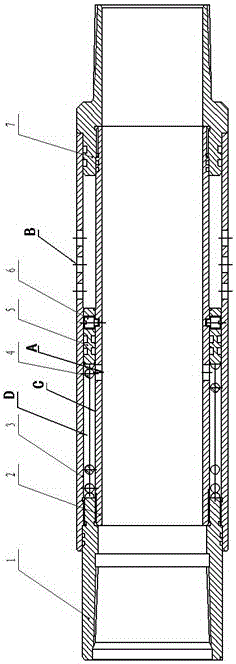

[0012] see figure 1 , the body of the drainer is composed of an upper joint, a working pipe and a lower joint; the upper and lower joints are fixed at both ends of the working pipe; A spring and a piston are arranged in the central circular space formed by the tube shell and the central tube, and the piston is provided with an unblocking pin perpendicular to the moving direction of the piston, and the central tube is also provided with a pressure inlet hole.

[0013] The pressure inlet hole is arranged on the central pipe between the upper joint and the piston.

[0014] The oil drain port is arranged on the working pipe casing between the lower joint and the piston.

[0015] The fixing pin of the unsealing pin is inserted in the fixing groove of the central tube.

[0016] The drainer is composed of an upper joint 1, a center pipe 2, a working pipe shell 3, a spring 4, a piston 5, an unblocking pin 6, and a lower joint 7. The upper end of the upper joint 1 is processed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com