A new type of petroleum wax removal device

A technology for removing equipment and petroleum wax, which is applied in the direction of cleaning equipment, wellbore/well parts, chemical instruments and methods, etc., can solve problems such as complex process and management, loss of economic benefits in oil fields, and increased cost of hot washing, etc., to achieve extended Effects of cleaning cycle, reduction of sewage discharge, and labor cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

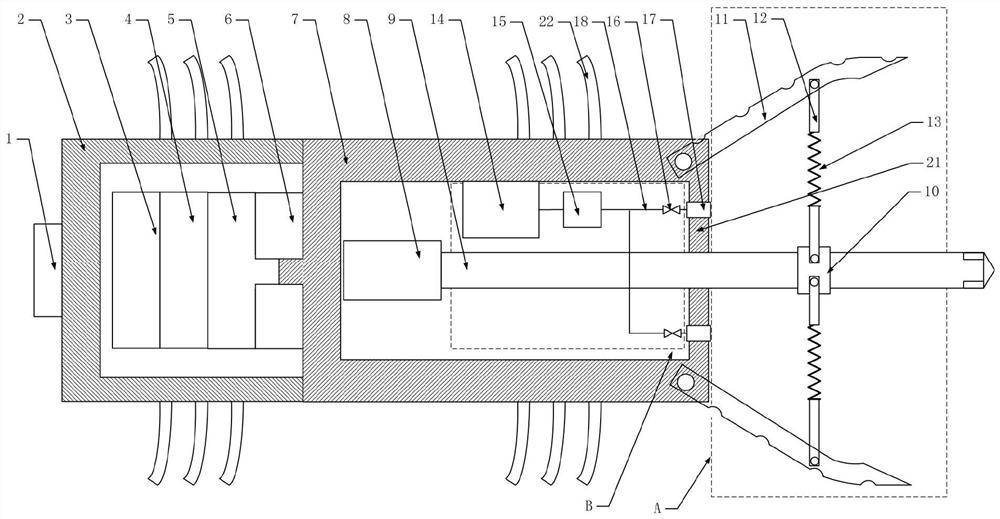

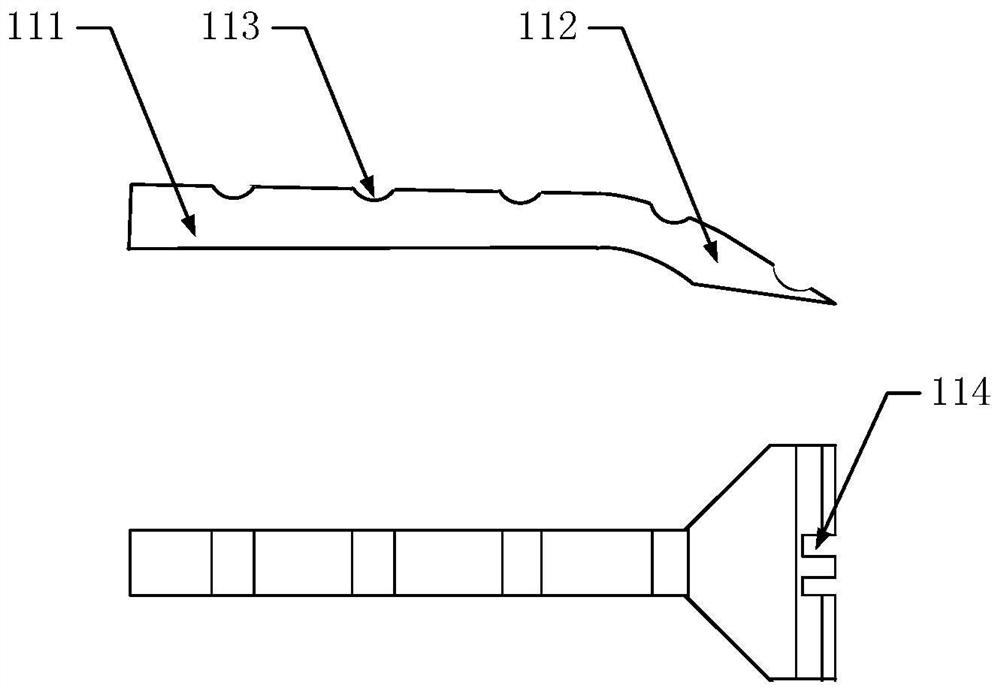

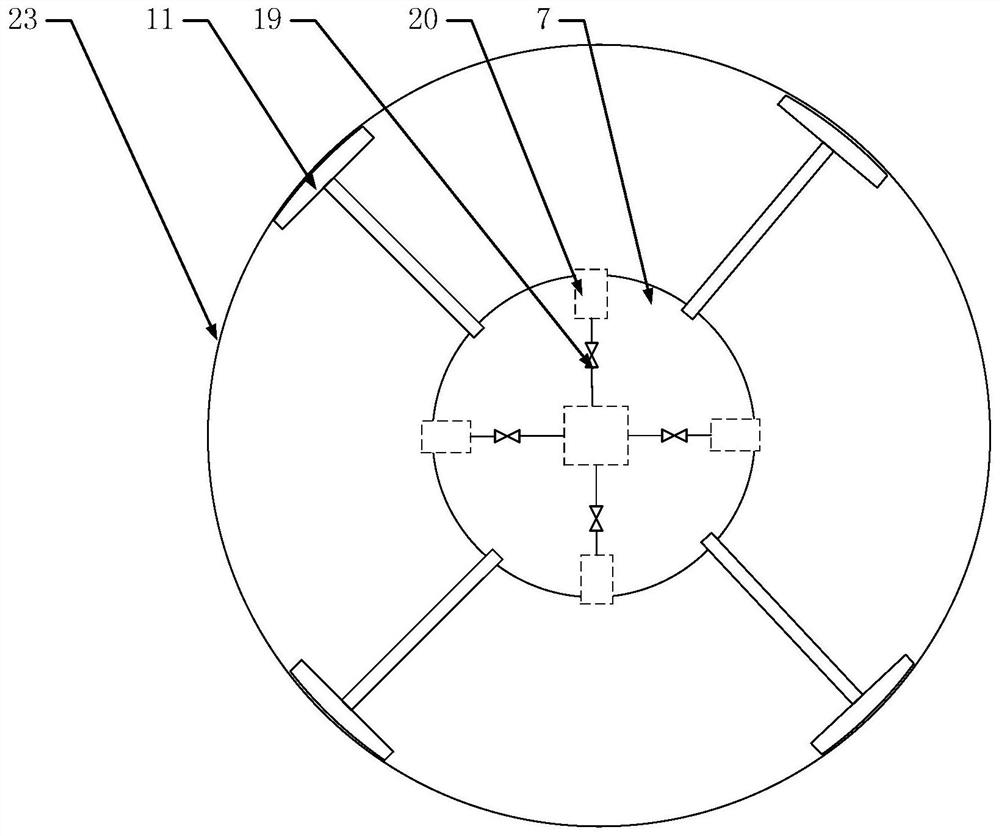

[0020] A new type of petroleum wax removal device, such as figure 1 As shown, including rope cap, control room, main control board, power module, first motor, coupling, swivel head, second motor, linear guide, slide table, tool assembly, liquid supply system, end cover, seal centralizer ring. The rope cap is located at the uppermost end of the wax remover, and the lower end is connected to the control room, which is a hollow cylindrical structure, and the main control board, the power module, the first motor and the shaft coupling are arranged in sequence inside it , the main control board includes a wireless transmission module for signal transmission with an external controller, the power supply module supplies power to all electrical components of the wax remover, and the first motor is connected to the rotary head through a coupling , the rotating head is a hollow cylindrical structure, inside which is provided with a second motor and a linear guide rail connected in sequ...

Embodiment 2

[0026] The device can choose to use different working modes according to the clogging degree of the petroleum pipeline. The working mode can be set according to the clogging degree of the petroleum pipeline. The working mode includes but not limited to the following two working modes:

[0027]General cleaning mode. When the blockage of the oil pipeline to be cleaned is not serious, the cutter assembly is in an open state, the second motor drives the slide table to move forward, and the wax removal knife is opened in the circumferential direction, and the spring can make the cutter head of the wax removal knife self-adaptive to different Diameter of the oil pipeline, and make the cutter head tightly fit on the inner wall of the oil pipeline; then, the liquid supply system starts to work continuously, and sprays the new wax preventive agent through the second nozzle group and adheres to the paraffin on the pipe wall , to achieve anti-wax treatment on the pipe wall after wax remo...

Embodiment 3

[0031] One of the main causes of wax deposition on the inner wall of the pipeline is that the crude oil absorbs the wax through the film. Specifically, when the oil-water emulsion contacts the oil pipe and the surface of the equipment, two types of orientation layers are usually formed, namely, a hydrophobic orientation layer and a hydrophilic orientation layer. . On the one hand, oil-soluble surfactants in hydrocarbons are adsorbed by the surface of oil pipes or equipment, forming an orientation layer with hydrophobic tendency and a crude oil film; on the other hand, when the crude oil film contacts with water without surfactant rupture, forming a hydrophilic alignment layer on its surface. At this time, a large amount of surfactants in hydrocarbons that have not been adsorbed by the metal surface begin to adsorb on this new oil-water interface in the form of hydrophilic groups absorbing water and hydrophobic groups absorbing oil, thus forming a double-layer surface active ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com