Cyclone wax removal device

A technology of swirl wax removal and cyclone, which is applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., which can solve the problems of small rotation force of collection liquid, small rotation force driven by water mixing, slow cooling speed of cold water, etc. problem, achieve fast cooling speed, solve wax deposition, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical scheme of the present invention will be further described below in conjunction with accompanying drawing, but should not be construed as limiting the present invention:

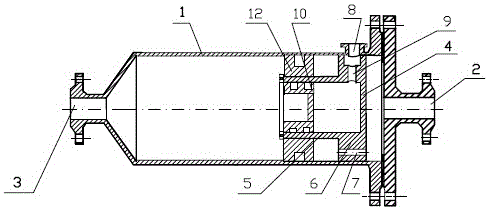

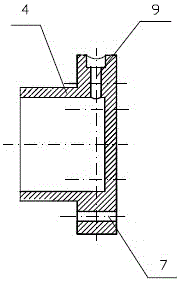

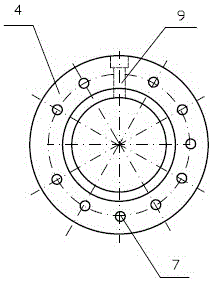

[0015] Fig. 1 is a sectional view of the present invention, Fig. 2 is a structural schematic diagram of a reversing deflector, Fig. 3 is a right view of a reversing deflector, Fig. 4 is a schematic structural diagram of an inlet spiral high-efficiency cyclone, and Fig. 5 is a water-mixed spiral high-efficiency cyclone Schematic diagram of the cyclone structure, as shown in the figure, a cyclone wax removal device, including the cyclone shell 1 inlet flange 2 and outlet flange 3, the inlet flange and the outlet flange are respectively installed in the swirl shell At both ends, the inlet end of the swirl shell is also equipped with a reversing deflector 4, and the center of the reversing deflector is a water-mixing pipe 5, and the water-adding pipe is located at the inlet end of the swirling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com