Composite lining design method with preliminary bracing as main bearing structure

A technology of initial support and design method, which is applied in the direction of shaft lining, tunnel lining, mining equipment, etc., to speed up the construction progress and improve the quality of tunnel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0021] The composite lining design method with primary support as the main load-bearing structure of the present invention, its preferred specific implementation mode is:

[0022] Including applicability judgment of primary support, primary support design method and secondary lining design method;

[0023] The primary support is mainly composed of anchor rods, shotcrete, steel mesh and steel frame. The applicability judgment of the primary support includes: the pH value of the groundwater is greater than 3, the groundwater does not contain sulfate and the water pressure is less than 0.2 MPa environment, the primary support is used as the main bearing structure of the composite lining;

[0024] The design method of the primary support includes: adopting the definition of the surrounding rock pressure arch, the boundary value of the surrounding rock pressure arch, and the plastic loosening pressure and deformation pressure proposed by the theoretical analysis, and the primary su...

specific Embodiment

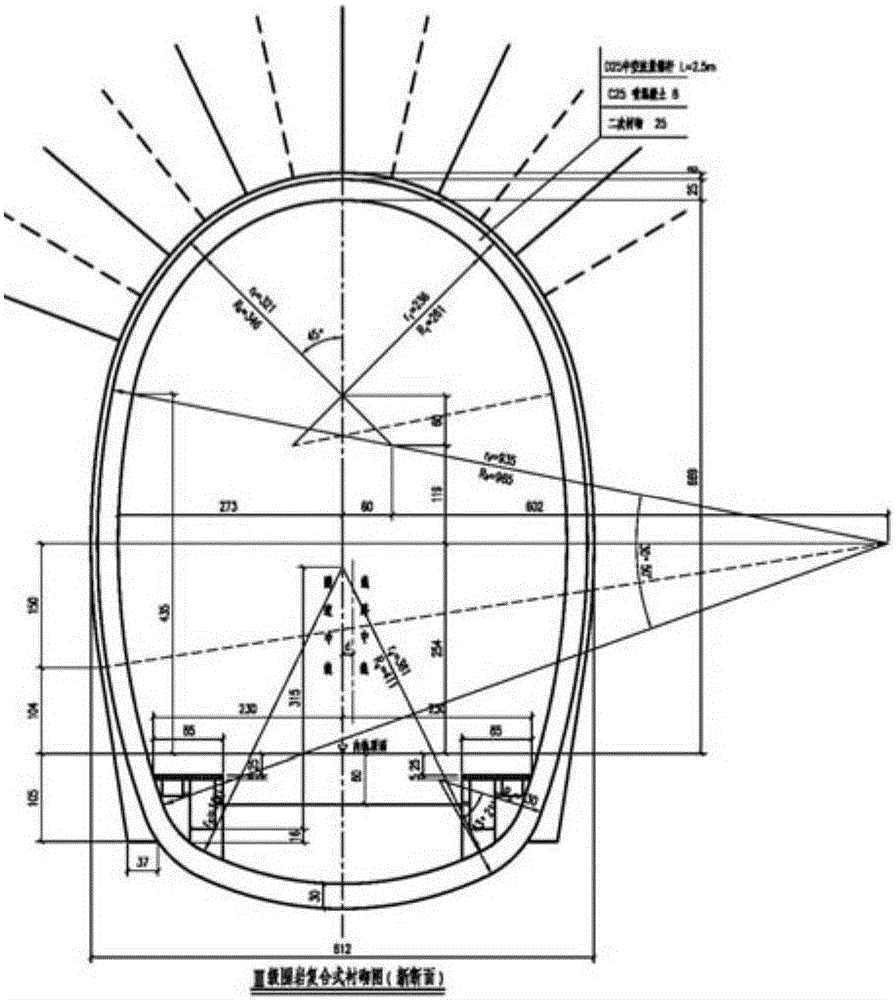

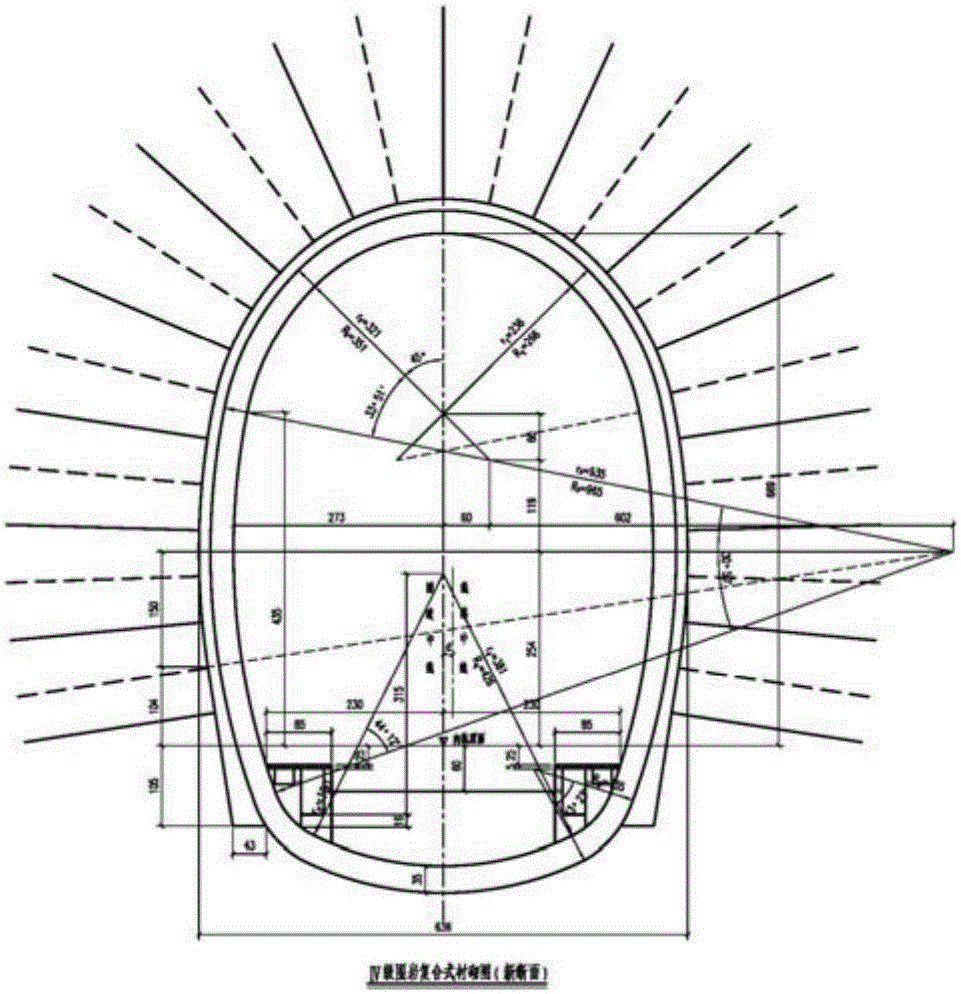

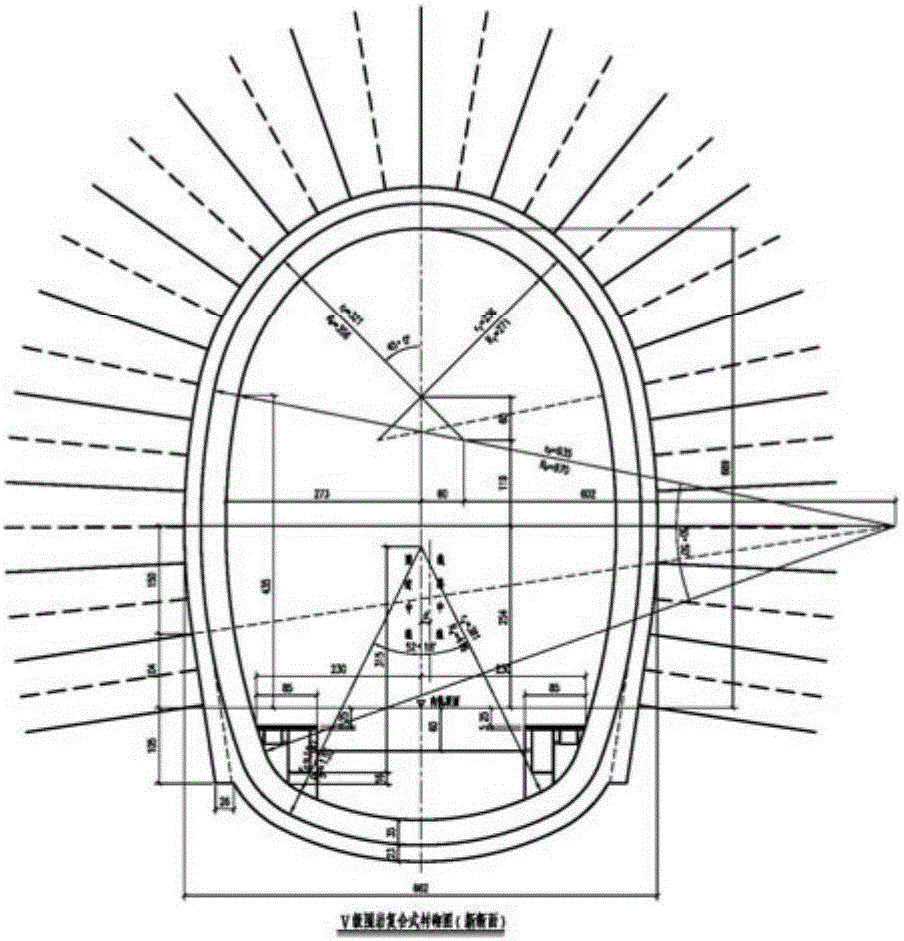

[0035] The present invention is implemented in Jiaozhuang Tunnel of Lianyan Railway, and optimized design is carried out for III, IV, and V surrounding rocks, and the optimized lining section is shown in the attached Figure 1~4 , the cross-section designed using the design method in the prior art is shown in the appendix Figure 5-8 , engineering quantity and economic benefit comparison are shown in Table 1. Construction monitoring data show that the structure is stable and meets the requirements.

[0036] Table 1 Comparison of main engineering quantities and economic benefits of 120km / h single-track tunnel:

[0037]

[0038] Note: A positive value in the table means that the optimized value is larger than the actual value, otherwise the actual value is smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com