Flat heat pipe with multi-channel sintered supporting structure and manufacturing method thereof

A support structure and flat heat pipe technology, which is applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of flat heat pipe heat transfer performance deterioration, long working fluid return path, and large return flow penetration resistance, etc., to improve the capillary limit , reduce osmotic resistance, increase the effect of capillary pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below through specific embodiments.

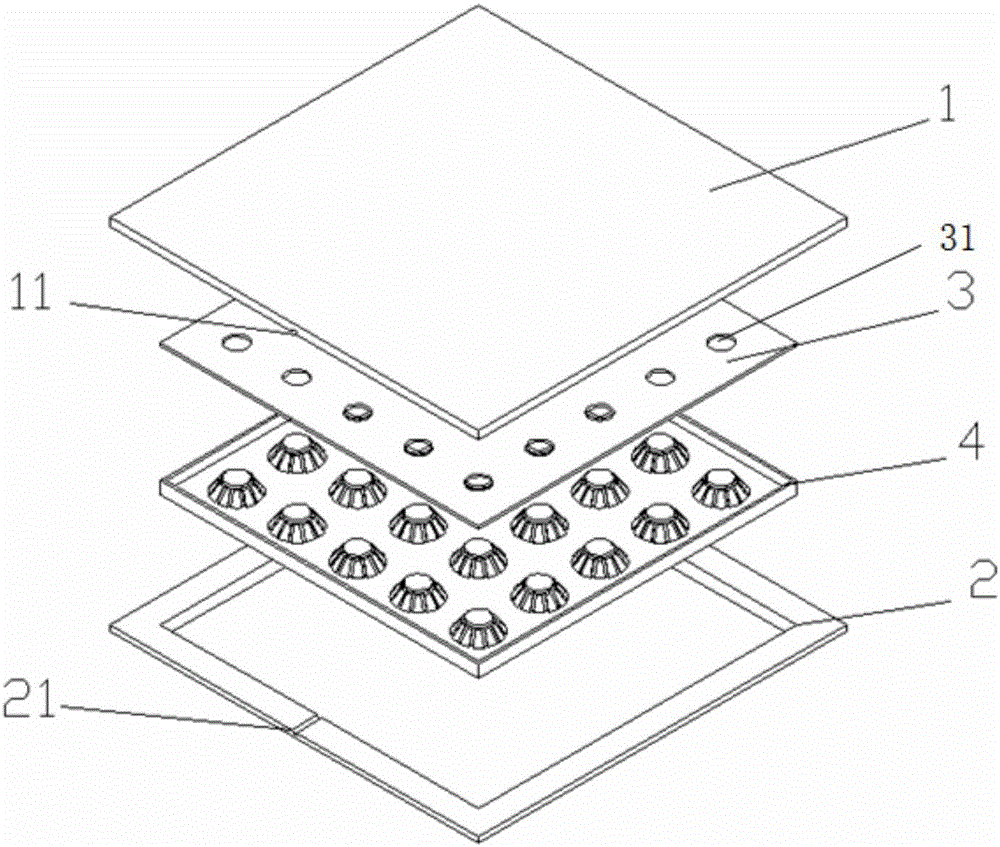

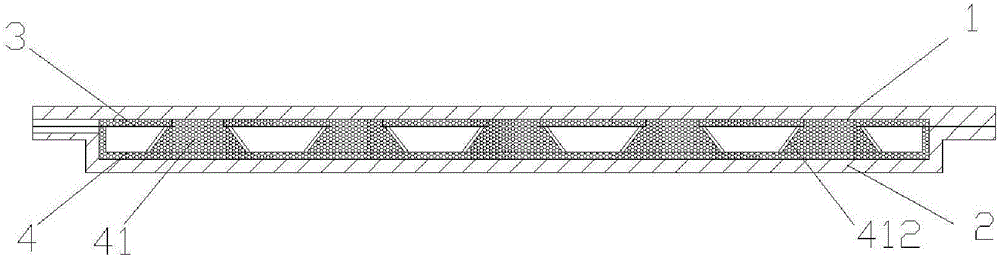

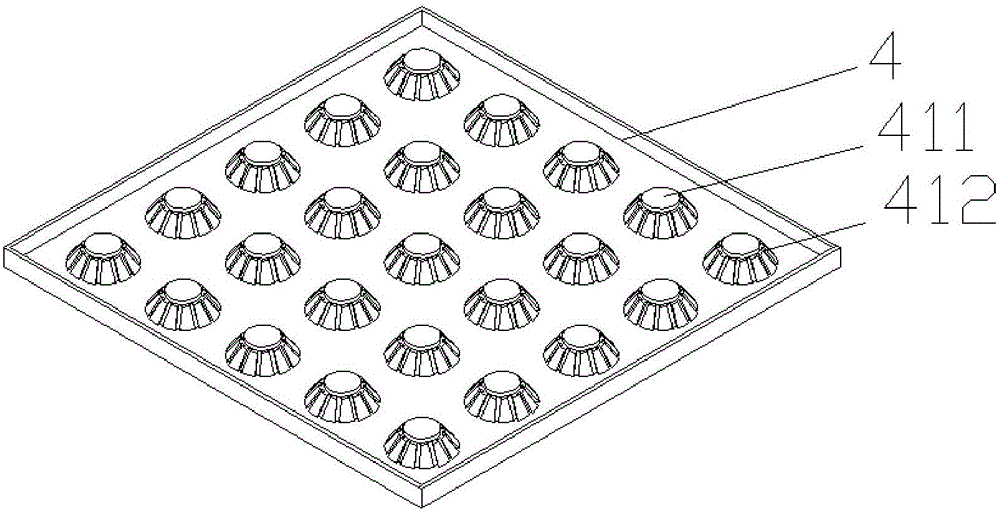

[0034] refer to Figure 1 to Figure 4 , a flat heat pipe with a multi-channel sintered support structure, comprising an upper metal cover 1 and a lower metal cover 2, the upper and lower metal cover 1, 2 are sealed and connected by welding to form a cavity, the cavity is filled with Liquid working medium. The inner surface of the upper metal cover plate 1 is used as a condensation surface, and the inner surface of the lower metal cover plate 2 is used as an evaporation surface, and thin-layer porous structures are laid respectively. A multi-channel sintered support structure with working fluid channels is also formed between the two thin-layer porous structures, and the two thin-layer porous structures and the multi-channel sintered support structure constitute the upper liquid-absorbent core 3 and the lower liquid-absorbent core 4 respectively.

[0035] The multi-channel sintered su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com