Working fluid

A working fluid and liquid technology, applied in the field of heat transfer, can solve problems such as poor stability of heat pipes, lower capillary performance of heat pipes, capillary limit of heat pipes, etc., and achieve the effect of improving heat transfer efficiency, increasing capillary limit, and increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

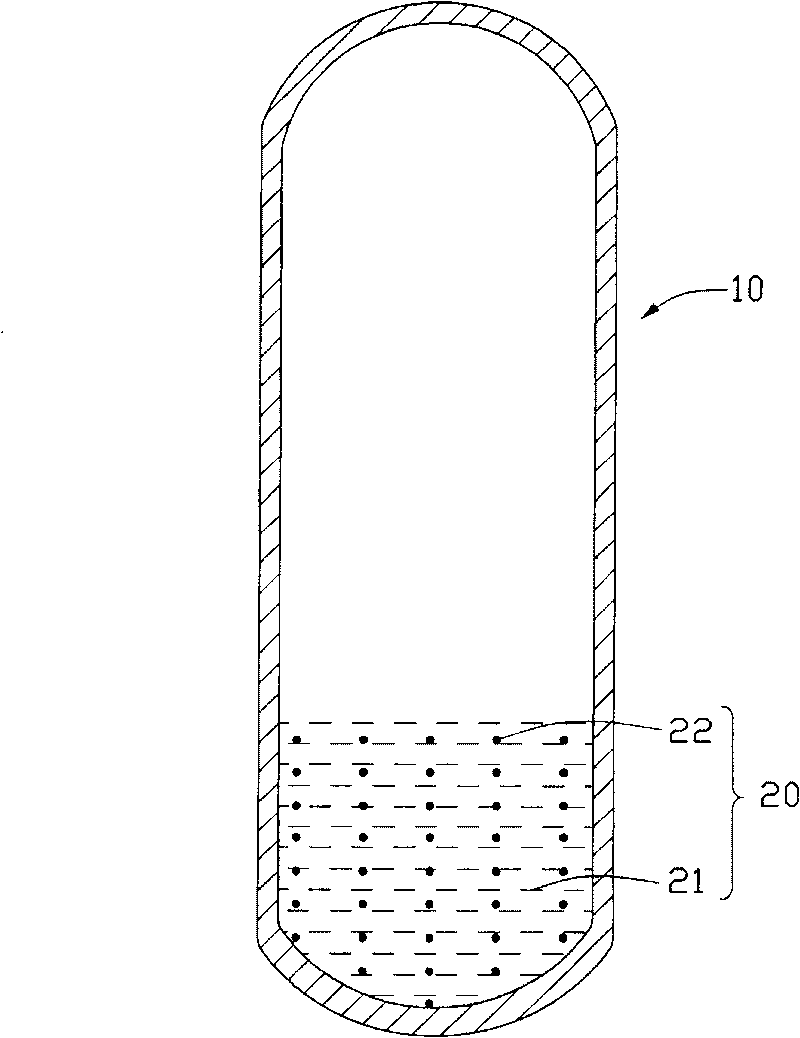

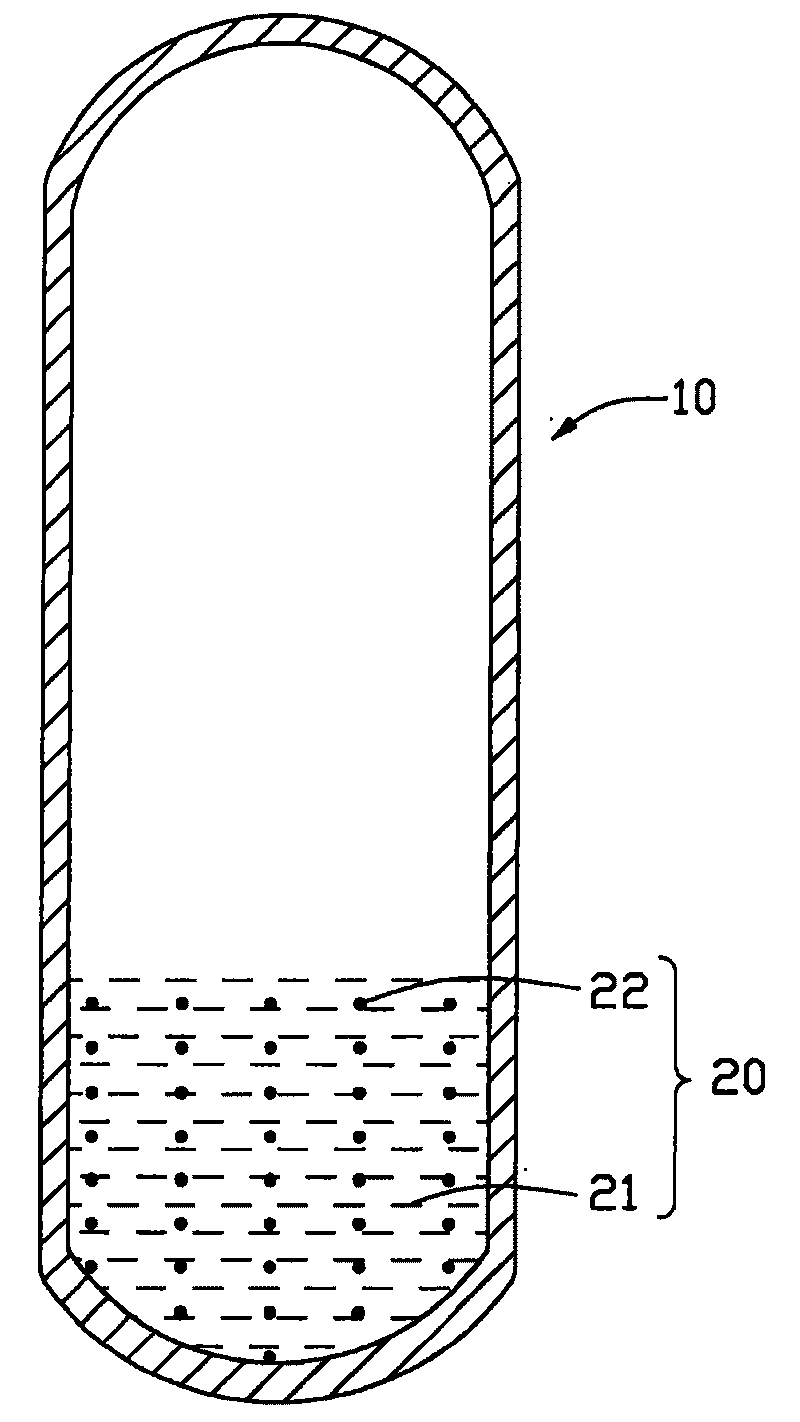

[0011] The present invention provides a working fluid that can be used in heat pipes, vapor chambers and other heat transfer devices. In this embodiment it is used for heat pipes, such as figure 1 As shown, the heat pipe 10 is a single-pipe heat pipe with a working fluid 20 inside it. The working fluid 20 includes a liquid 21 whose surface tension increases with increasing temperature, and a plurality of nanoparticles 22 dispersed in the liquid 21 .

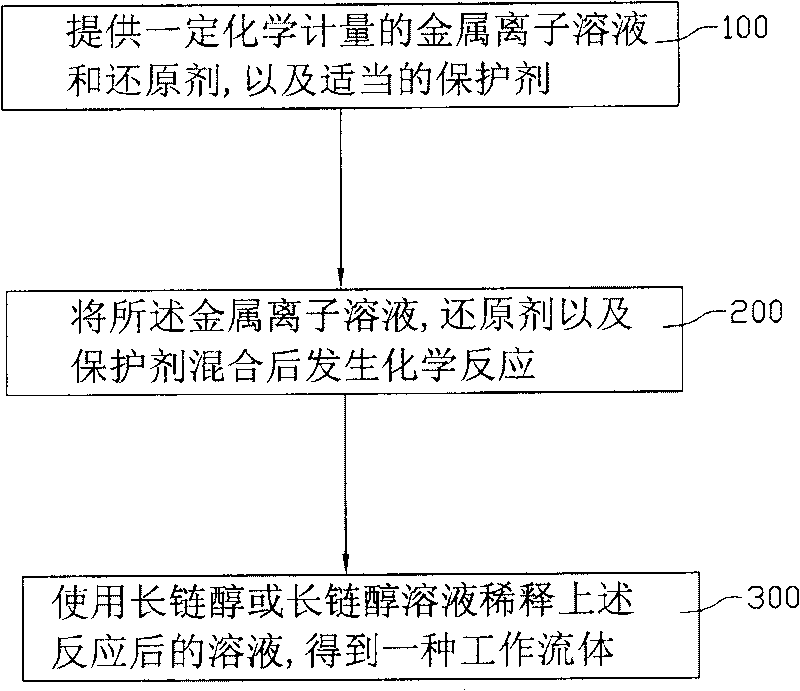

[0012] The liquid 21 may be a solution containing long-chain alcohol, or only long-chain alcohol. When the liquid 21 is a solution containing long-chain alcohol, its solvent can be selected from one or a mixture of water, methanol, ethanol, propanol and acetone. The long-chain alcohol can be selected from one or a mixture of alcohols with 4 to 10 carbon atoms, which can be straight-chain alcohols or branched-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com