Initial strain control apparatus for distributed fiber sensor of pipe and control method thereof

A distributed optical fiber and optical fiber sensor technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems that do not involve the initial strain control method and device of distributed optical fiber sensors, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

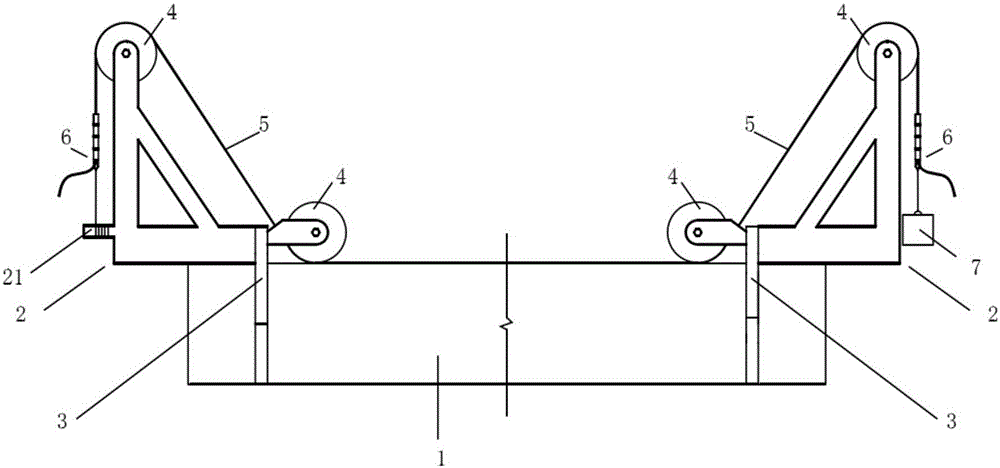

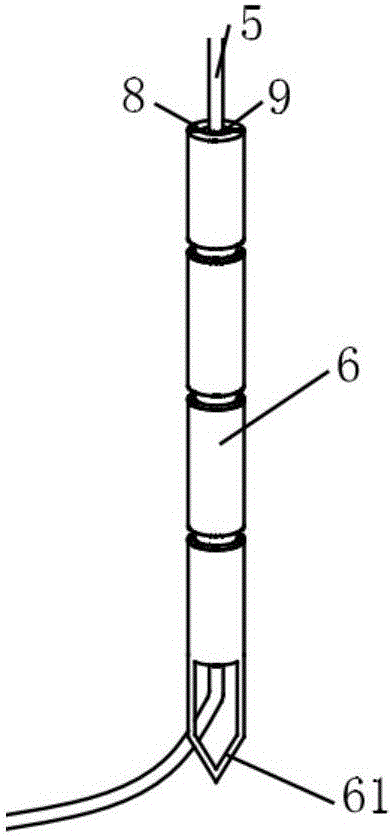

[0030] This embodiment provides a pipeline distributed optical fiber sensor initial strain control device, which is used to uniformly stretch the distributed optical fiber sensor 5 and lay it on the surface of the pipeline 1 to be detected. figure 1 , 2 , which mainly includes two pulley fixing units, pulley 4, weight 7 and fiber optic sensor binding appliance 6.

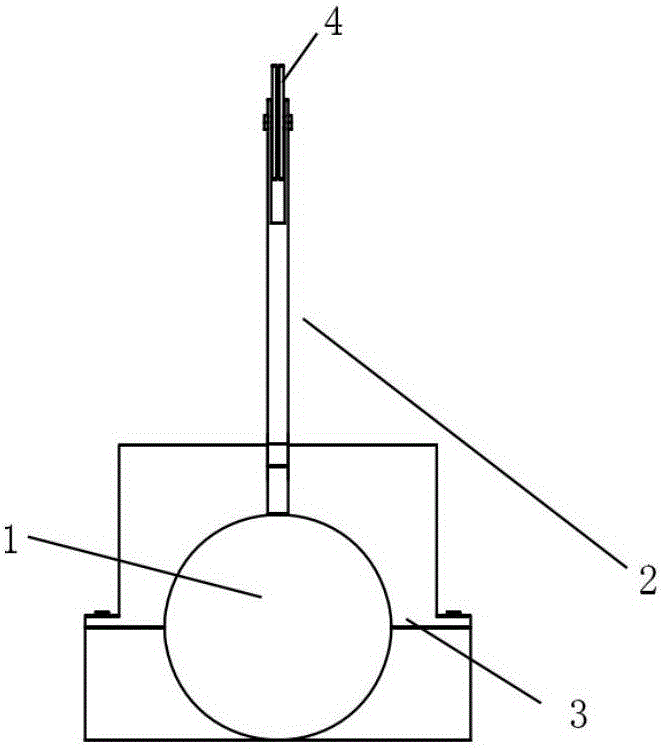

[0031] The pulley fixing unit is composed of a rigid bracket 2 and a ring clamp 3, and the ring clamp 3 is fastened on the pipeline 1 by bolts, and the specific size of its inner diameter matches the outer diameter of the pipeline; the rigid bracket 2 is composed of a cross bar , the vertical rod and the diagonal brace are fixedly connected, the horizontal rod is fixedly connected above the ring clamp 3, the vertical rod is vertically fixed on the outer end of the horizontal rod, and the diagonal brace is fixedly connected between the above vertical rod and the horizontal rod, It plays the role of rigid support for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com