Device and method for simulating influences of underground water on coalbed methane

A simulation device and coalbed methane technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as complex structure of the simulation device, inability to meet the simulation of large coal samples, and inability to confirm the impact of coalbed methane storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

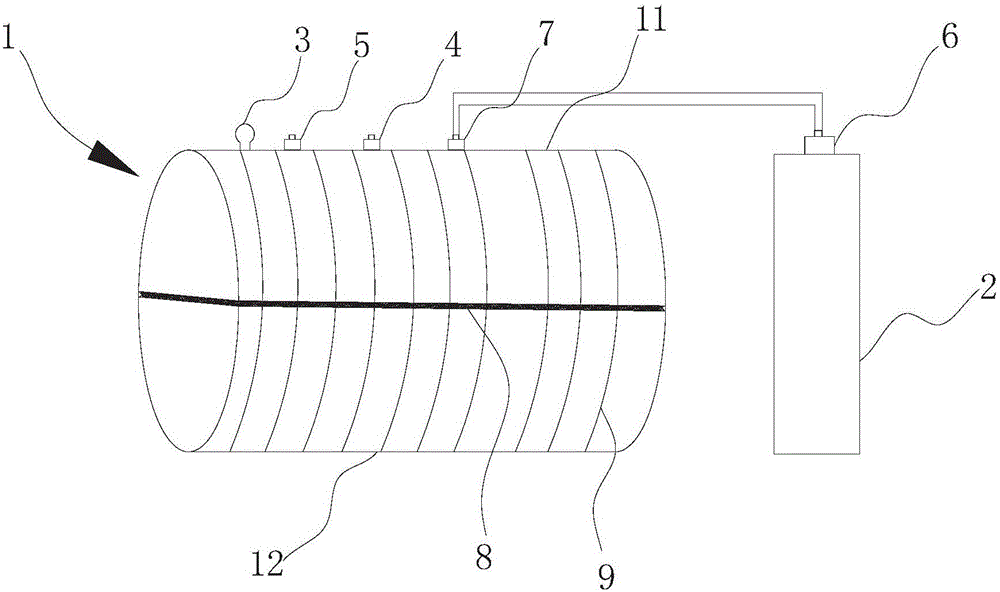

Image

Examples

Embodiment 1

[0038] S1 Determine the influence of research pressure on coalbed methane, then set the coal-water mass ratio, water quality and coal quality as 20:1, total salinity 0.5g / L, lignite, and set the different values of pressure as 1MPa, 5MPa, 10MPa, 15MPa.

[0039] S2 performs the following operations on each value of the pressure;

[0040] Separate the two half cylinders of the pressure tank, put the coal sample and water in a set ratio of 20:1, wherein the water quality needs to meet the condition of a total salinity of 0.5g / L, and close the pressure tank; and The induction coil of the induction heating coil is wound on the surface of the pressure tank;

[0041] Open the pressure reducing valve and the air inlet connection valve, release the gas to the pressure tank at a certain flow rate through the high-pressure gas bottle, check the pressure of the pressure tank through the pressure gauge until it reaches the set pressure value (1MPa, 5MPa, 10MPa, 15MPa); The induction co...

Embodiment 2

[0045] S1 is determined to study the influence of coal-water mass ratio on coalbed methane, and then set the pressure, water quality and coal quality as 1MPa, total salinity 0.5g / L, and lignite respectively, and set the different values of coal-water mass ratio to 20 :1, 10:1, 5:1, 1:1, 1:10, 1:20;

[0046] S2 performs the following operations for each value of the coal-water mass ratio;

[0047] Separate the two half cylinders of the pressure tank, put the coal sample and water in the set ratio (20:1, 10:1, 5:1, 1:1, 1:10, 1:20), wherein The water quality needs to meet the condition of total salinity of 0.5g / L, close the pressure tank; and the induction coil of the induction heating coil is wound on the surface of the pressure tank;

[0048]Open the pressure reducing valve and the air inlet connection valve, release the gas to the pressure tank at a certain flow rate through the high-pressure gas bottle, check the pressure of the pressure tank through the pressure gauge un...

Embodiment 3

[0052] S1 determines the influence of water quality on coalbed methane, and then sets the pressure, coal-water mass ratio and coal quality as 1MPa, 20:1, and lignite respectively, and sets the different values of water quality as total salinity of 0.5g / L, The total salinity is 2g / L, the total salinity is 8g / L, the total salinity is 25g / L, and the total salinity is 60g / L;

[0053] S2 performs the following operations on each value of the water quality;

[0054] Separate the two half cylinders of the pressure tank, put the coal sample and water in a set ratio of 20:1, wherein the water quality value of the water meets the set conditions (total salinity 0.5g / L, total mineralization 2g / L, total salinity 8g / L, total salinity 25g / L, total salinity 60g / L), close the pressure tank; and the induction coil of the induction heating coil is wound on the surface of the pressure tank;

[0055] Open the pressure reducing valve and the air inlet connection valve, release the gas to the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com