A method for preparing magnetic abrasive particles by sol-gel method

A magnetic abrasive particle and gel method technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of uneven mixing of abrasive particles and magnetic media, and difficulty in crushing, achieving low cost and simplifying the preparation process. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of aluminum oxide monohydrate:

[0018] (1) Preparation of aluminum sol: Mix 10g of aluminum isopropoxide and 87.66ml of deionized water according to the molar ratio of 1:100, prepare 88ml of mixed solution, stir at a speed of 300r / min for 5min, mix well, and mix according to HNO 3 : Aluminum isopropoxide: The molar ratio of deionized water is 1:2:200, add 1.4ml of HNO dropwise 3 , the addition rate is controlled at 1 drop / second, continue to stir and mix, and then put it in a water bath, heat up the water bath to 90°C, seal the plastic wrap and mechanically stir for 10 hours, and continue to mechanically stir for 1.5 hours with the open mouth, and control the stirring speed to 300r / min, forming aluminum sol;

[0019] The reaction principle is: .

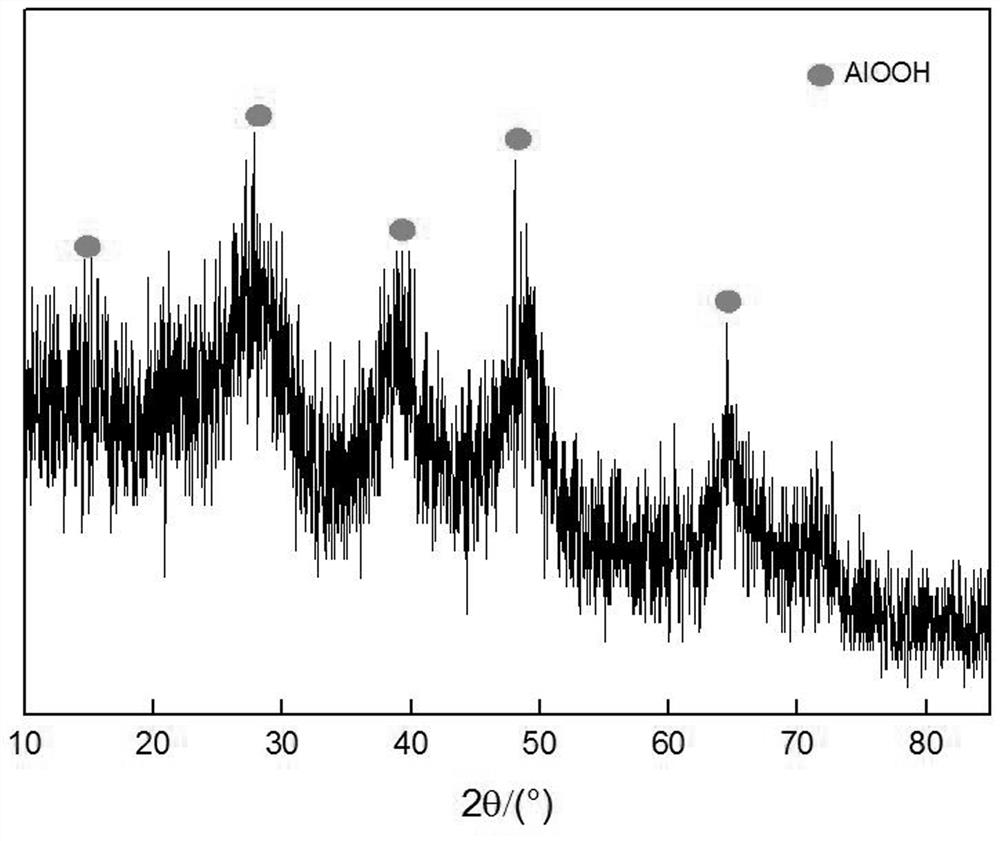

[0020] (2) Preparation of AlOOH (alumina monohydrate) particles: After aging the aluminum sol at room temperature for 12 hours, put it in a drying oven, control the temperature in the drying...

Embodiment 2

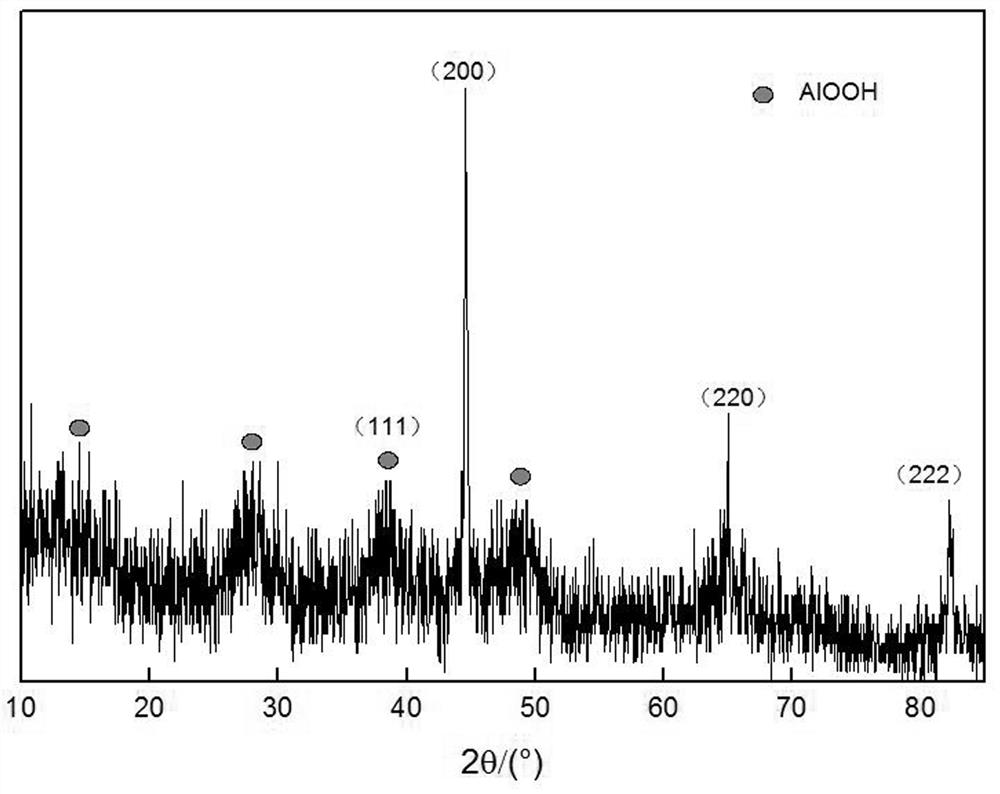

[0022] Embodiment 2: the preparation of Fe-AlOOH magnetic abrasive grain:

[0023] (1) Preparation of iron-based particles: Mix 5g of citric acid and distilled water at a mass ratio of 1:10 and dissolve in distilled water to prepare a citric acid-distilled aqueous solution with a pH value of 2, according to the mass ratio of carbonyl iron powder to citric acid Weigh 1.6g of 3-5um carbonyl iron powder at a ratio of 1:3 and add it to the prepared citric acid-distilled aqueous solution to form A liquid, then place it in an ultrasonic disperser for ultrasonic dispersion for 30 minutes, stir for 30 minutes to mix evenly, and then put A liquid Filtration, washing, drying, and the dried powder is evenly ground to form iron-based particles;

[0024] (2) Preparation of aluminum sol: Mix 10g of aluminum isopropoxide and 87.66ml of deionized water according to the molar ratio of 1:100 to form 88ml, stir at a speed of 300r / min for 5min, mix well, and mix according to HNO 3 : Aluminum iso...

Embodiment 3

[0033] Embodiment 3: A method for preparing magnetic abrasive particles by a sol-gel method, mixing carbonyl iron powder, citric acid, and distilled water to make carbonyl iron powder-citric acid distilled aqueous solution, drying it, and grinding the dried powder into iron base particles; aluminum isopropoxide was dissolved in deionized water, and then HNO was added dropwise in aqueous isopropanol 3 After the addition is completed, heat in a water bath and stir to form an aluminum sol; add dry and ground iron-based particles to the aluminum sol and stir to form an iron-based aluminum sol, and after aging at room temperature, dry in a drying oven to form Fe-AlOOH magnetic abrasive particles .

[0034] Specific steps are as follows:

[0035] (1) Preparation of iron-based particles: Mix 5g of citric acid and distilled water at a mass ratio of 1:10 and dissolve in distilled water to prepare a citric acid-distilled aqueous solution with a pH value of 2, according to the mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com