Amido modified magnetic nano-particle and method for preparing immune magnetic nano-separation agent

A magnetic nanoparticle and magnetic nanoparticle technology, which is applied in the field of preparation of immunomagnetic nano-separation reagents, can solve the problems of unsuitability for industrial production and low yield, and achieve the effects of improved synthesis efficiency, good dispersion, and fast magnetic separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

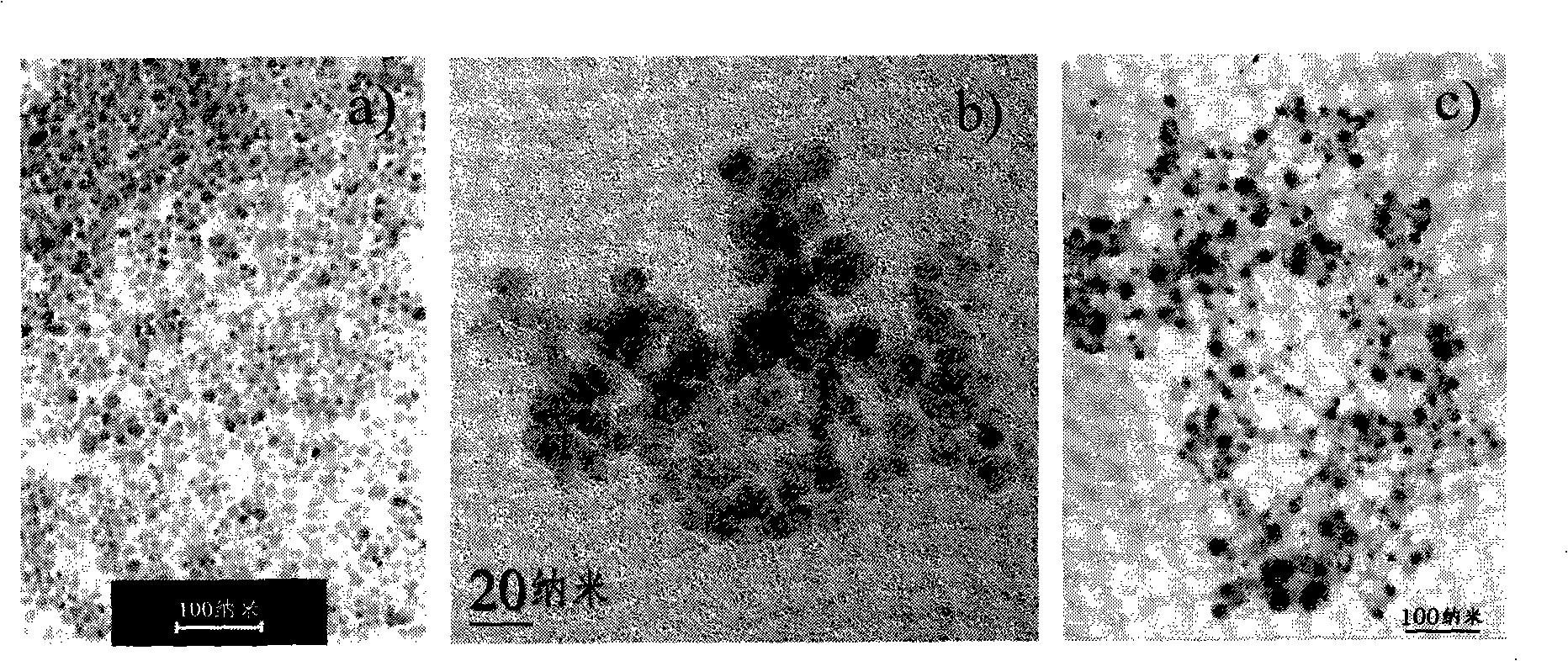

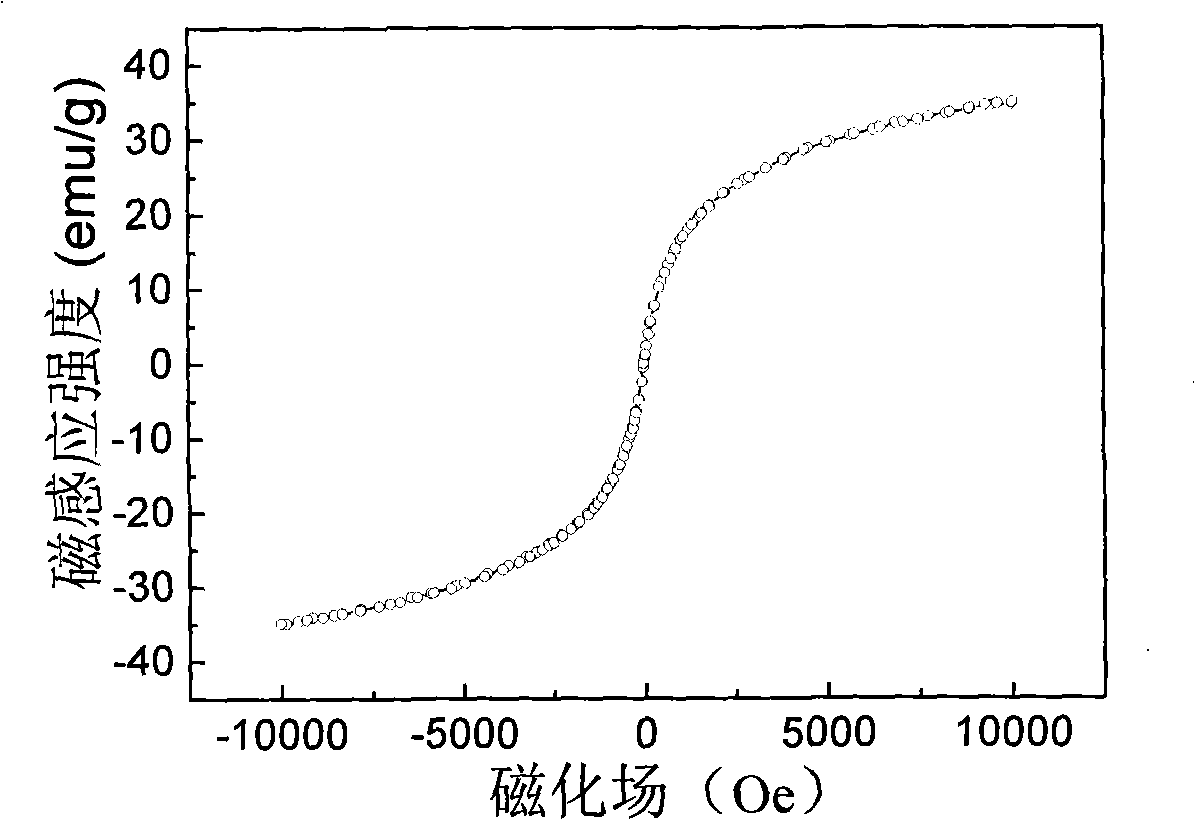

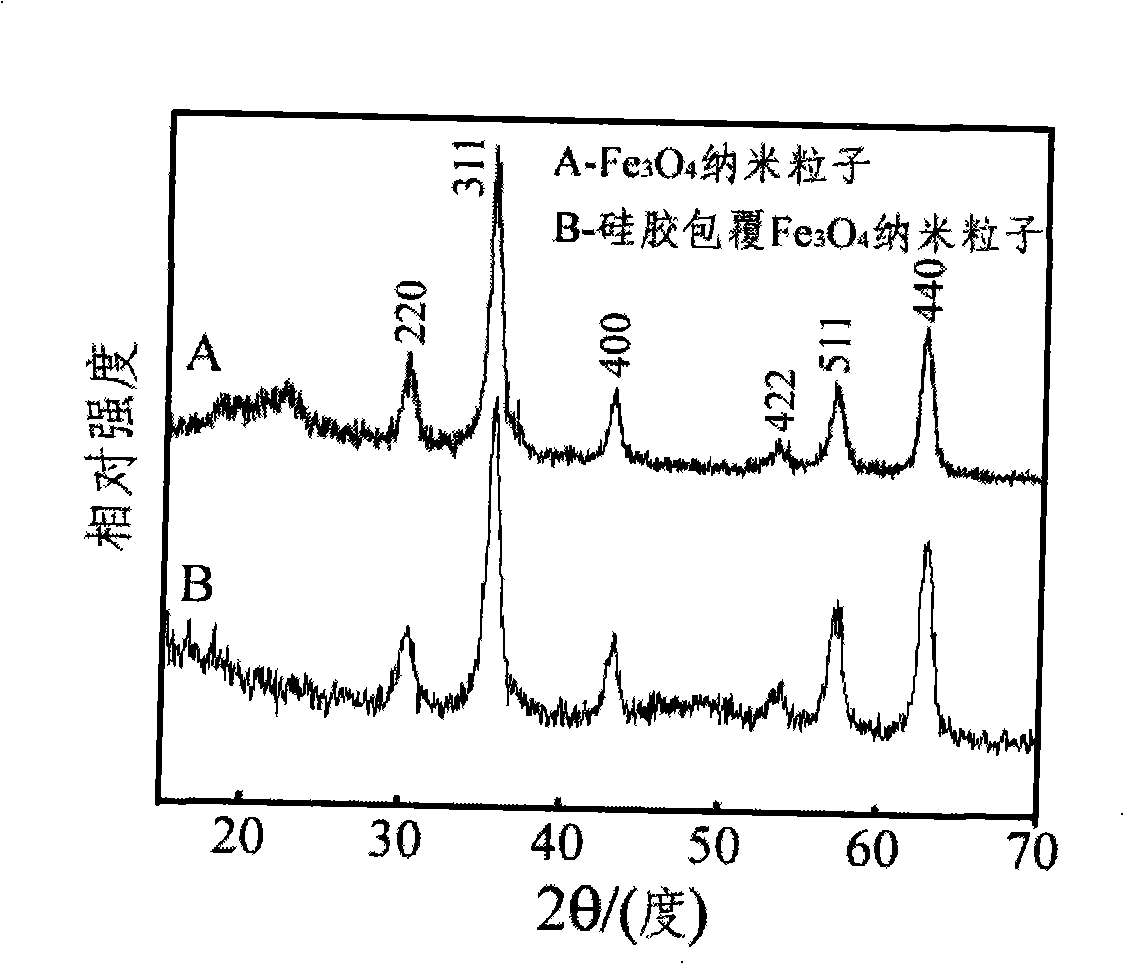

[0035] 1) Prepare 1250ml 0.5M NaOH and 125ml 1M FeCl respectively 3 , 125ml 0.5M FeCl 2 and 125ml 0.4M HCl solution, NaOH solution was placed in a three-necked flask, under N 2 Heating the constant temperature water bath to 60°C under protective conditions, the prepared FeCl 3 , FeCl 2 After mixing with HCl solution, it was quickly added to a three-necked flask, stirred at 50 rpm for 15 min, and then cooled to room temperature. Washed 5 times with deionized water and methanol successively, the resulting product Fe 3 o 4 Magnetic nanoparticles are dispersed in methanol. The TEM image of the obtained product is shown in figure 1 Shown in (a); And detect the magnetic property of product, as figure 2 The hysteresis curve is shown.

[0036] 2) The product prepared in the previous step (Fe dispersed in methanol 3 o 4 Magnetic nanoparticles, Fe 3 o 4 Magnetic nanoparticles (20 g) are placed in a flask, a total of 1000 ml of toluene and methanol are added at a volume rati...

Embodiment 2

[0041] 1) Prepare 1250ml 0.5M KOH and 125ml 1M Fe respectively 2 (SO 4 ) 3 , 125ml 0.5M FeSO 4 and 125ml of 0.4M HCl solution, the KOH solution was placed in a three-necked flask, heated to 70°C at a constant temperature under the protection of argon (Ar), and the prepared Fe 2 (SO 4 ) 3 , FeSO 4 After mixing with HCl solution, it was quickly added into a three-necked flask, stirred vigorously at 100 rpm for 20 min, and then cooled to room temperature. Washed several times with deionized water and ethanol successively, the obtained product Fe 3 o 4 Magnetic nanoparticles are dispersed in ethanol.

[0042] 2) Put 20 g of magnetic nanoparticles prepared in the previous step in a flask, add 1050 ml of toluene and ethanol at a volume ratio of 1:15, add 10 ml of sodium silicate, and heat up the flask to 100° C. Stir vigorously at 100 rpm, reflux for 24 hours, and wash with toluene several times to obtain Fe coated with silica gel. 3 o 4 magnetic nanoparticles.

[0043] ...

Embodiment 3

[0047] 1) Prepare 1250ml 0.5M KOH and 125ml 1M Fe respectively 2 (SO 4 ) 3 , 125ml 0.5M FeSO 4 and 125ml 0.4M HCl solution, put the KOH solution in a three-necked flask, under N 2 Heating at constant temperature to 90°C under protective conditions, the prepared Fe 2 (SO 4 ) 3 , FeSO 4 After mixing with HCl solution, it was quickly added into a three-necked flask, stirred vigorously at 80 rpm for 30 min, and then cooled to room temperature. Wash several times with deionized water and methanol successively, and the obtained product Fe 3 o 4 Magnetic nanoparticles were dispersed in methanol.

[0048] 2) Put 20 g of the magnetic nanoparticles prepared in the previous step in a flask, add 1000 ml of toluene and methanol at a volume ratio of 1:30, add 200 ml of tetraethyl orthosilicate, and heat up the flask to 120° C. 2 Protected, stirred vigorously at a speed of 80rpm, refluxed for 30h, and washed several times with toluene to obtain Fe coated with silica gel. 3 o 4 ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com