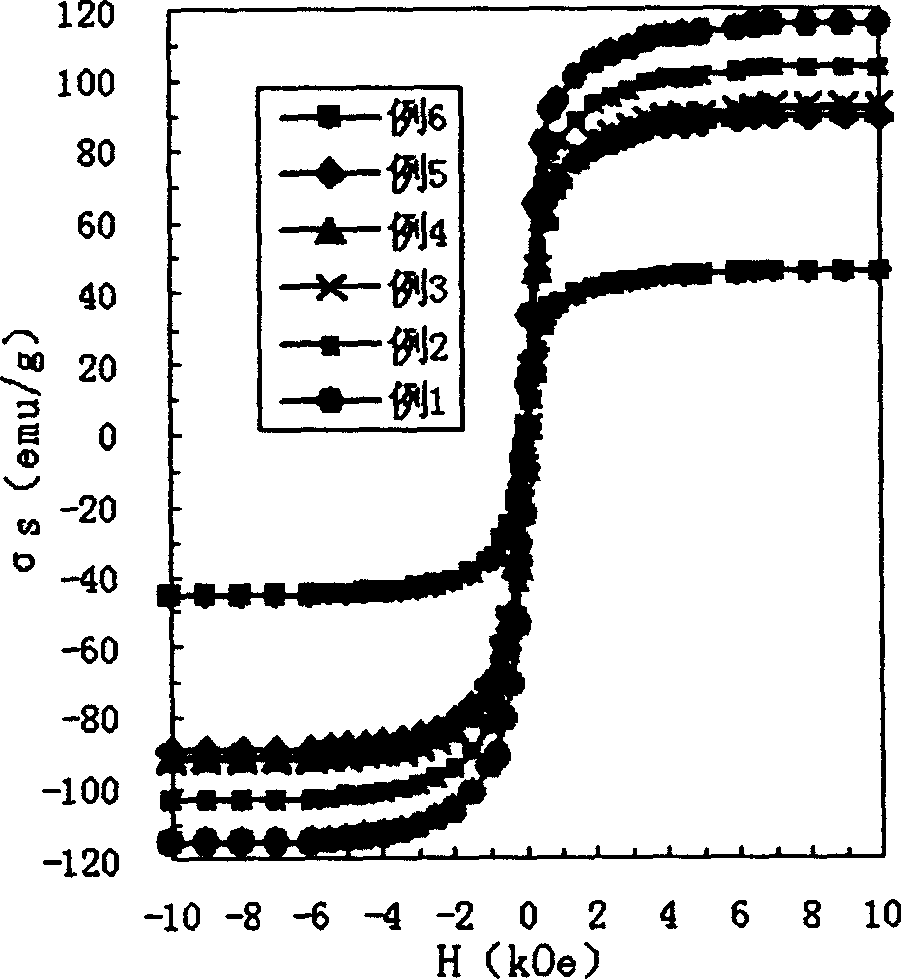

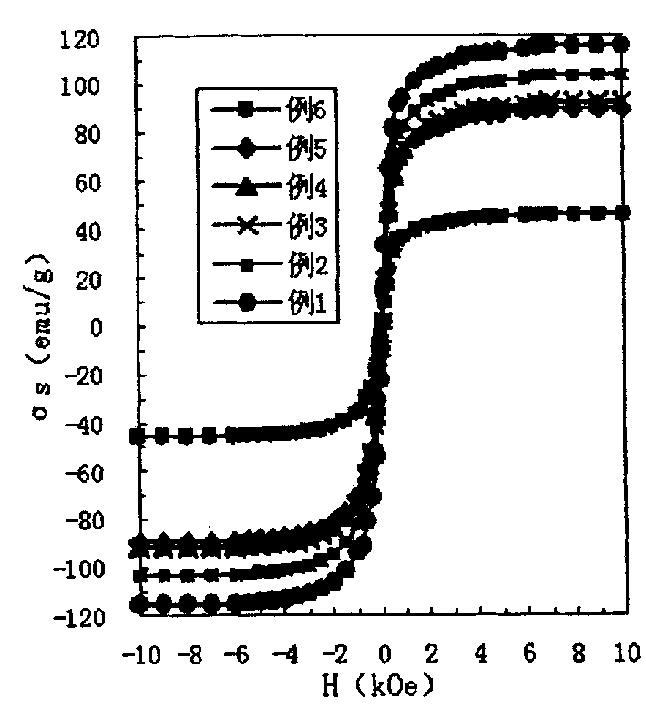

High specific saturated magnetizing strengh Fe3O4 micro particles and its preparing method

A magnetization, high-ratio technology, used in inductor/transformer/magnet manufacturing, iron oxide, inorganic material magnetism, etc., can solve problems such as lower than saturation magnetization, achieve good magnetic responsiveness, simple preparation process, and dosage. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Prepare high specific saturation magnetization Fe according to the following steps 3 o 4 particle

[0018] 1. The air in the 1000ml four-neck garden bottom flask equipped with stirring, filling inert gas, constant pressure dropping funnel, and vacuum device is replaced with nitrogen;

[0019] 2. Weigh 3.2g FeCl respectively 3 ·6H 2 O(AR) and 1.7g FeSO 4 ·7H 2 Put O(AR) into the reactor prepared in step 1, add 50 times the weight of deoxygenated pure water to dissolve, and stir to form a uniform solution;

[0020] 3. Weigh 4g NaOH (AR), dissolve it with 400ml deoxygenated pure water to form an aqueous NaOH solution of about 3M, add it to a constant pressure dropping funnel, and stir it under N 2 It was dripped into the reactor under air protection, and a black solution was obtained after the dripping was completed.

[0021] 4. Add an aqueous solution containing 0.5 g of oleic acid to the black solution obtained in step 3, and stir for 1-2 hours.

[...

Embodiment 2

[0026] Embodiment 2: Prepare high specific saturation magnetization Fe according to the following steps 3 o 4 particle

[0027] 1. The air in the 1000ml four-necked round bottom flask equipped with stirring, filling inert gas, constant pressure dropping funnel and vacuum device is replaced with argon;

[0028] 2. Weigh 3.2g FeCl respectively 3 ·6H 2 O(AR) and 1.2g FeCl 2 4H 2 Put O(AR) into the reactor prepared in step 1, add 50 times the weight of deoxygenated pure water to dissolve, and stir to form a uniform solution;

[0029] 3. Weigh 5g of NaOH(AR), dissolve it with 400ml of deoxygenated pure water into about 3M NaOH aqueous solution, add a constant pressure dropping funnel, drop it into the reactor under stirring and Ar gas protection, and get a black solution after dropping .

[0030] 4. Add an aqueous solution containing 0.6 g of sodium oleate to the black solution obtained in step 3, and stir for 1 to 2 hours.

[0031] 5. Add the product obtained in step 4 int...

Embodiment 3

[0035] Embodiment 3: Prepare high specific saturation magnetization Fe according to the following steps 3 o 4 particle

[0036] 1, the air in the 1000ml four-neck garden bottom flask equipped with stirring, filling inert gas, constant pressure dropping funnel, and vacuum device is replaced with nitrogen;

[0037] 2. Weigh 4.0g NaOH(AR), put it into the reactor prepared in step 1, add 40 times the weight of deoxygenated pure water to dissolve NaOH, and stir to form a uniform solution;

[0038] 3. Weigh 3.2g FeCl respectively 3 ·6H 2 O(AR) and 1.7g FeSO 4 ·7H 2 O(AR), dissolved into an aqueous solution with 1000ml of deoxygenated pure water, added to a constant pressure dropping funnel, stirred and N 2 It was dripped into the reactor under air protection, and a black solution was obtained after the dripping was completed.

[0039] 4. Add an aqueous solution containing 0.7 g of sodium dodecylbenzenesulfonate to the black solution obtained in step 3, and stir for 1 to 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com