Power transmission line sag measurement method based on infrared camera image processing

An infrared camera and image processing technology, applied in image data processing, measurement devices, image enhancement, etc., can solve the problems of short distance between obstacles, prone to short-circuit between phases, and large wire stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

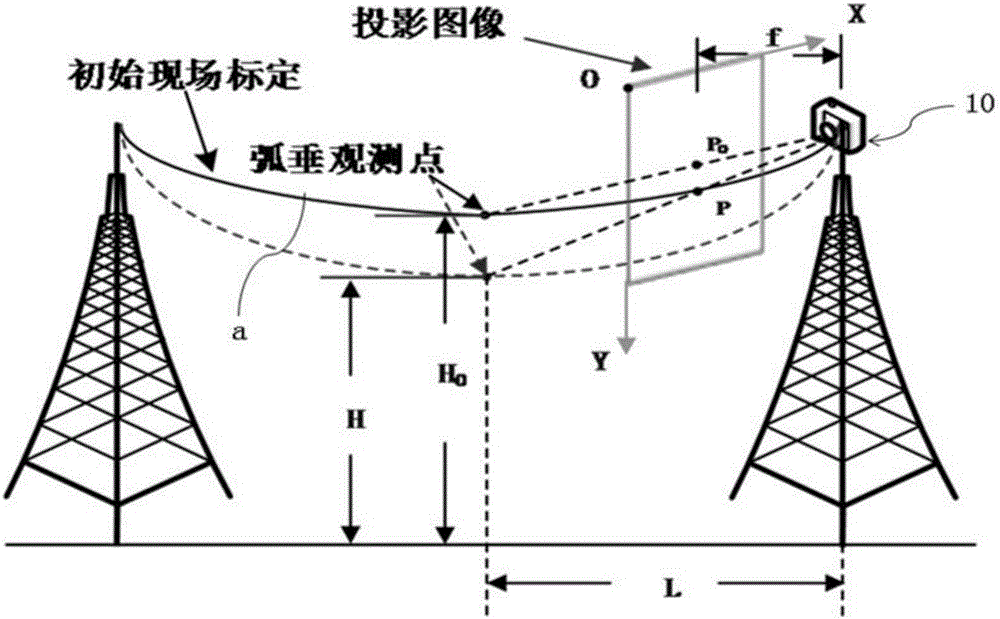

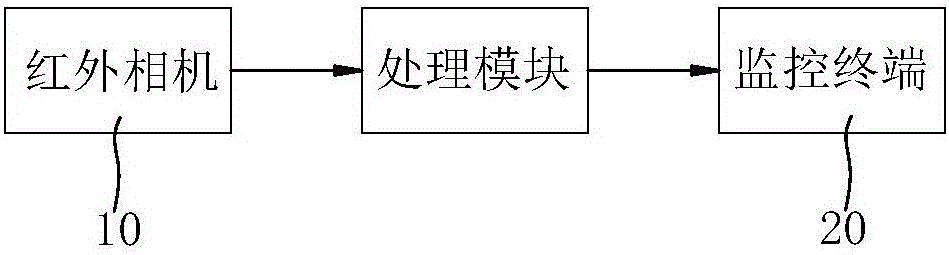

[0058] to combine Figure 1 to Figure 4 , the present invention is further described:

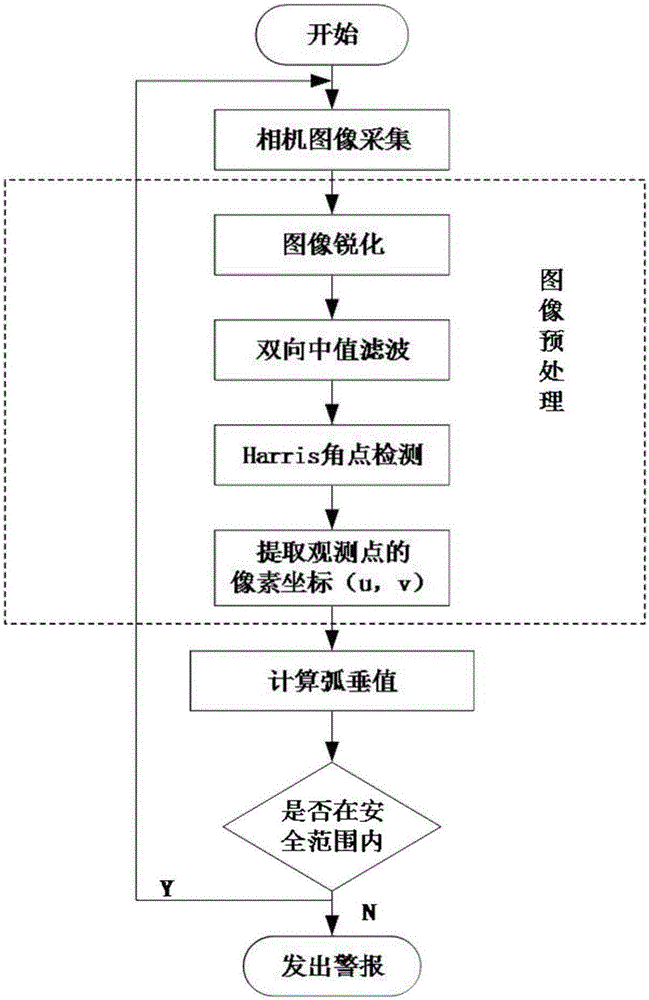

[0059] A transmission line sag measurement method based on infrared camera image processing, the measurement method includes the following steps:

[0060] Step A), the measurement site and the infrared camera 10 are calibrated;

[0061] Step B), obtain the image information near the sag observation point through the infrared camera, process the image, and extract the pixel coordinates P(u,v) of the observation point;

[0062] In step C), the processed image data obtained in step B is calculated to obtain the sag H of the transmission line;

[0063] Step D), judging whether the transmission line sag H is within the safe range, if the transmission line sag H is not within the safe range, the information is sent to the monitoring terminal 20, and the monitoring terminal 20 receives the information and outputs an alarm message; if the transmission line sag H Within safe limits, return to step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com